Bipod with compressively popping up inner leg assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

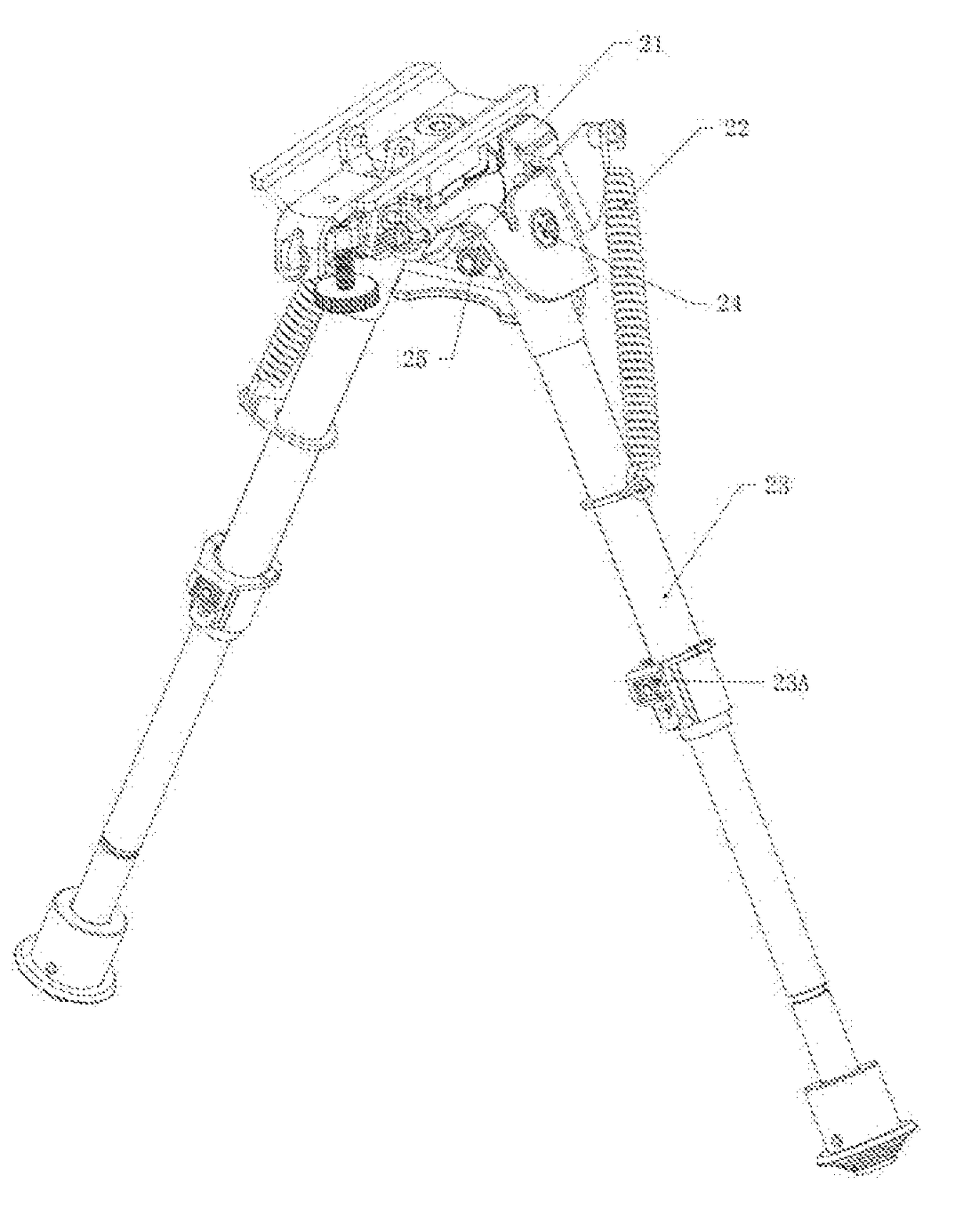

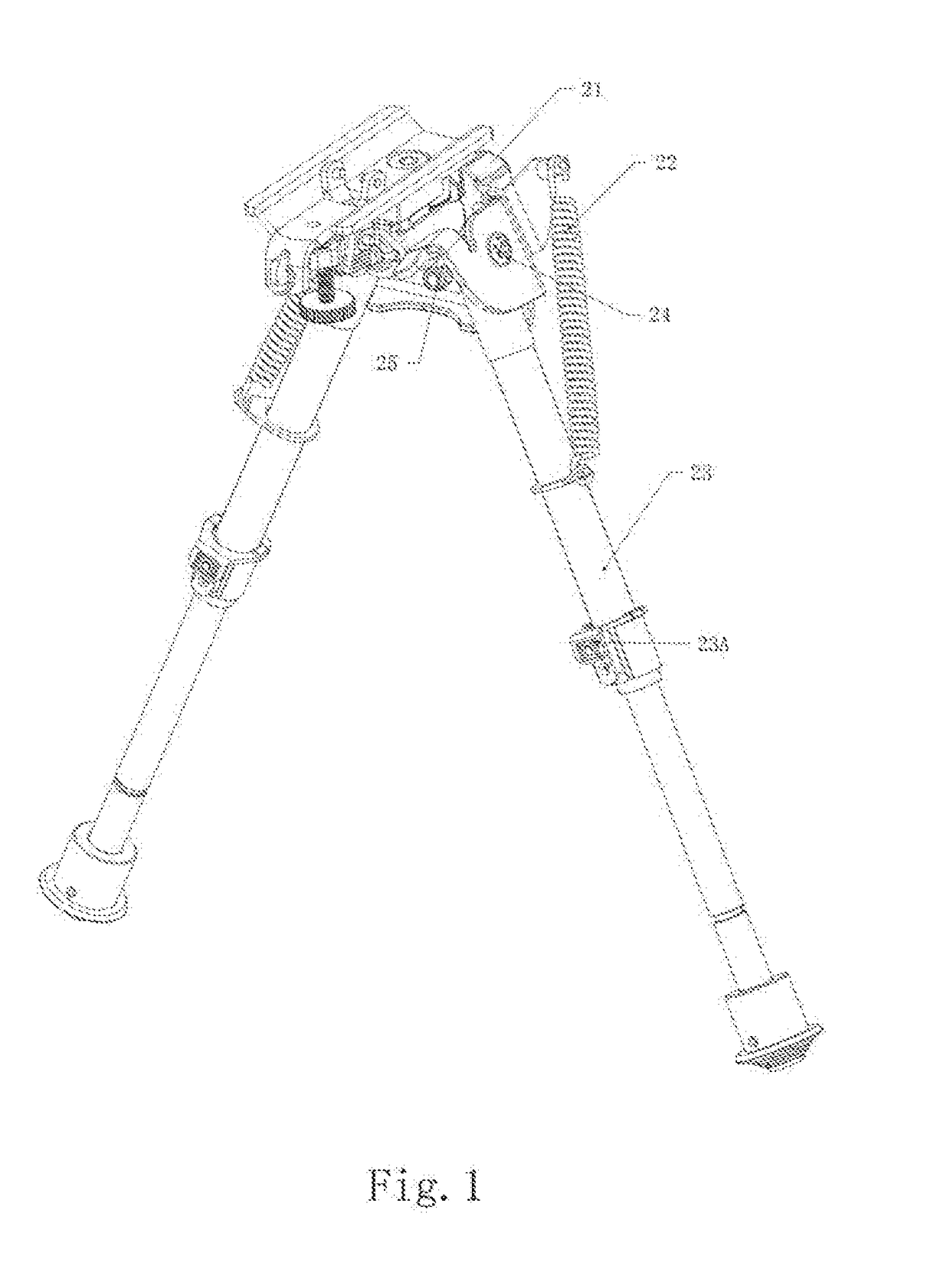

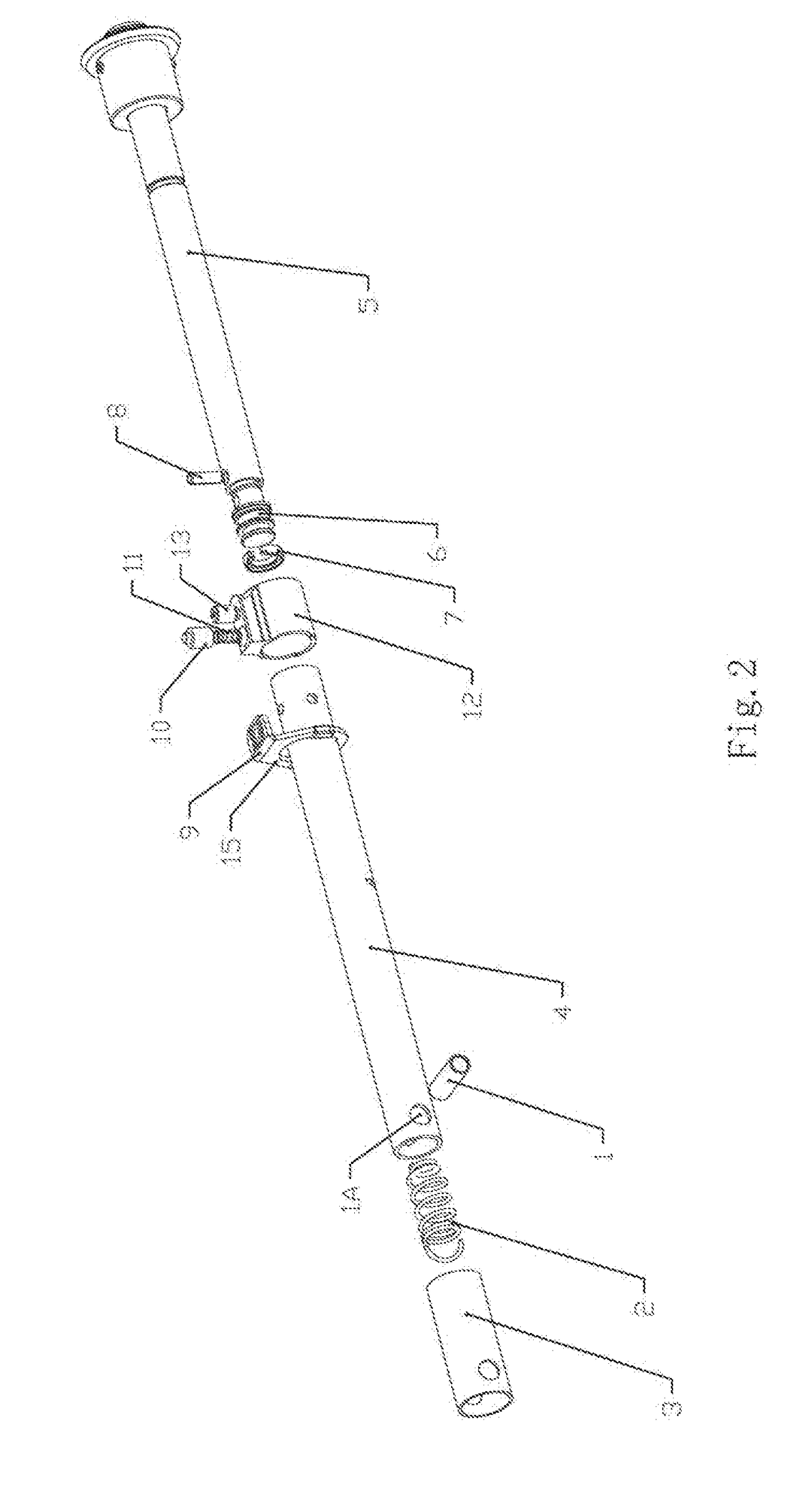

[0039]FIGS. 1-10 are illustrative embodiments of a bipod with compressively popping up inner leg assemblies according to the present invention, in some of which the specific structure details are only illustrative descriptions for explaining the technical solutions of the present invention, but not meant to limit the present invention. Where there are the same structures in each embodiment according to the present invention, for the sake of simplicity, different embodiments may refer to the same drawings for description.

[0040]FIG. 1 is a perspective view of a first embodiment of a bipod according to the present invention, which comprises a bracket assembly 21; at least two pop up inner leg assemblies 23 pivotally connected to the bottom of the bracket assembly 21.

[0041]Specifically, the bipod further comprises leg reset springs 22, socket hexagon screws 24 with half-round heads and outer hexagon nuts 25. The socket hexagon screw 24 with half-round head is for connecting the inner le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com