Knitted Mattress Cover, Mattress and Method for Manufacturing a Knitted Mattress Cover

a mattress cover and knitted technology, applied in the field of knitted mattress covers, can solve the problems of bringing down both production costs and production time, and achieve the effects of reducing labor costs, cost-effectiveness, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

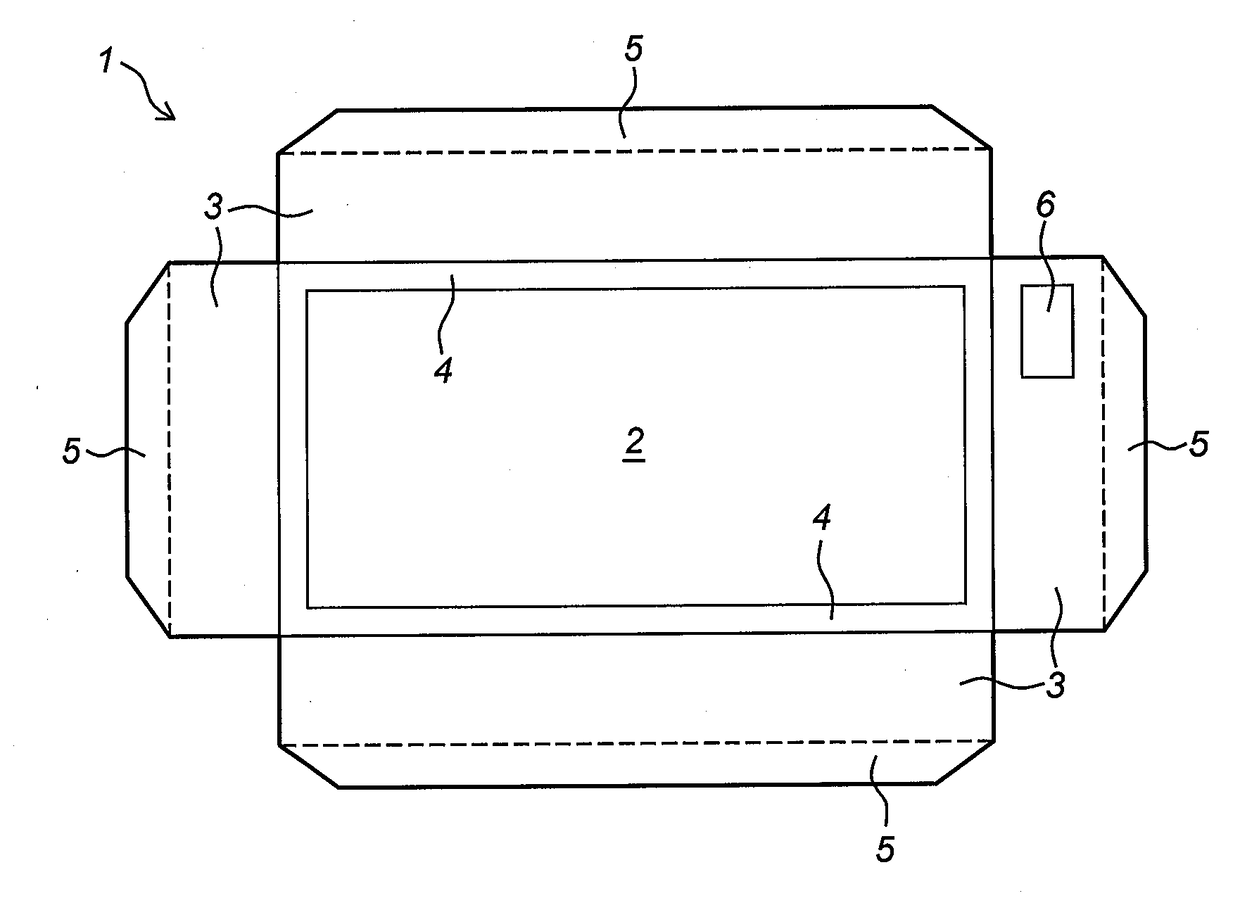

[0020]FIG. 1 depicts a plan view of a knitted mattress cover 1 according to an embodiment of the invention. The mattress cover, also known as the ticking, comprises a top panel 2 and multiple side panels 3. A tape edge 4 connects the top panel 2 with each of the side panels 3. The side panels are at a free end thereof provided with gussets 5. The mattress cover 1 could amongst others comprises a cotton or a linen textile. The top panel 2 and / or the side panels 3 may be provided with patterning or a logo 6, which pattern or logo 6 is directly knitted into the fabric of the mattress cover 1. The mattress cover as shown in FIG. 1 is able to fully enclose the top and sides of a mattress. However, it is also possible that the mattress cover encloses only part of the mattress, wherein additional panels are provided to connect with the mattress and cover the complete mattress core.

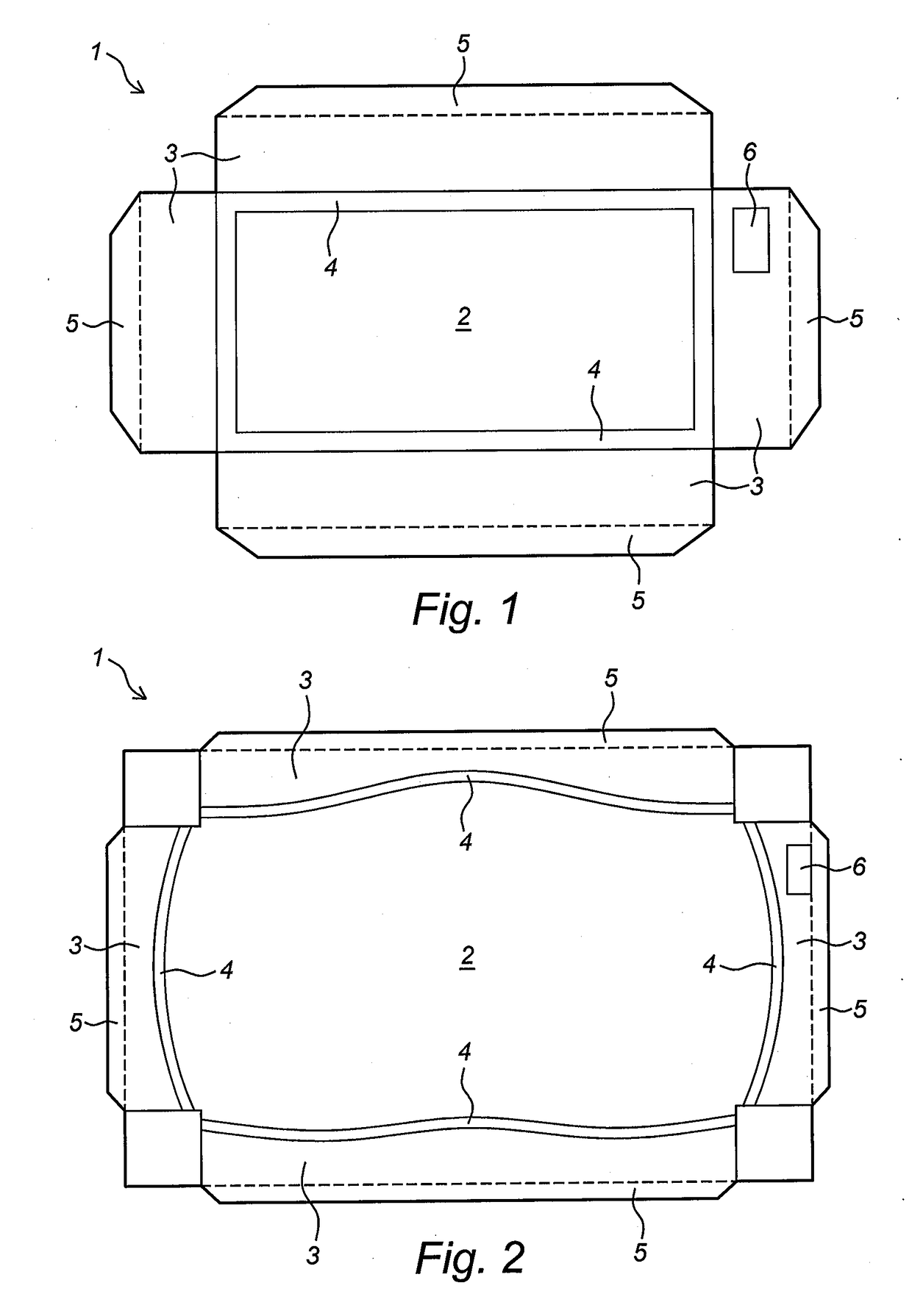

[0021]FIG. 2 shows another plan view of a knitted mattress cover 1 according to an embodiment of the invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com