Digital camera focus self-calibration

a digital camera and self-calibration technology, applied in the field of digital cameras, can solve the problems of inconsistency between specific profiles and thermal expansion and contraction, and is susceptible to thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

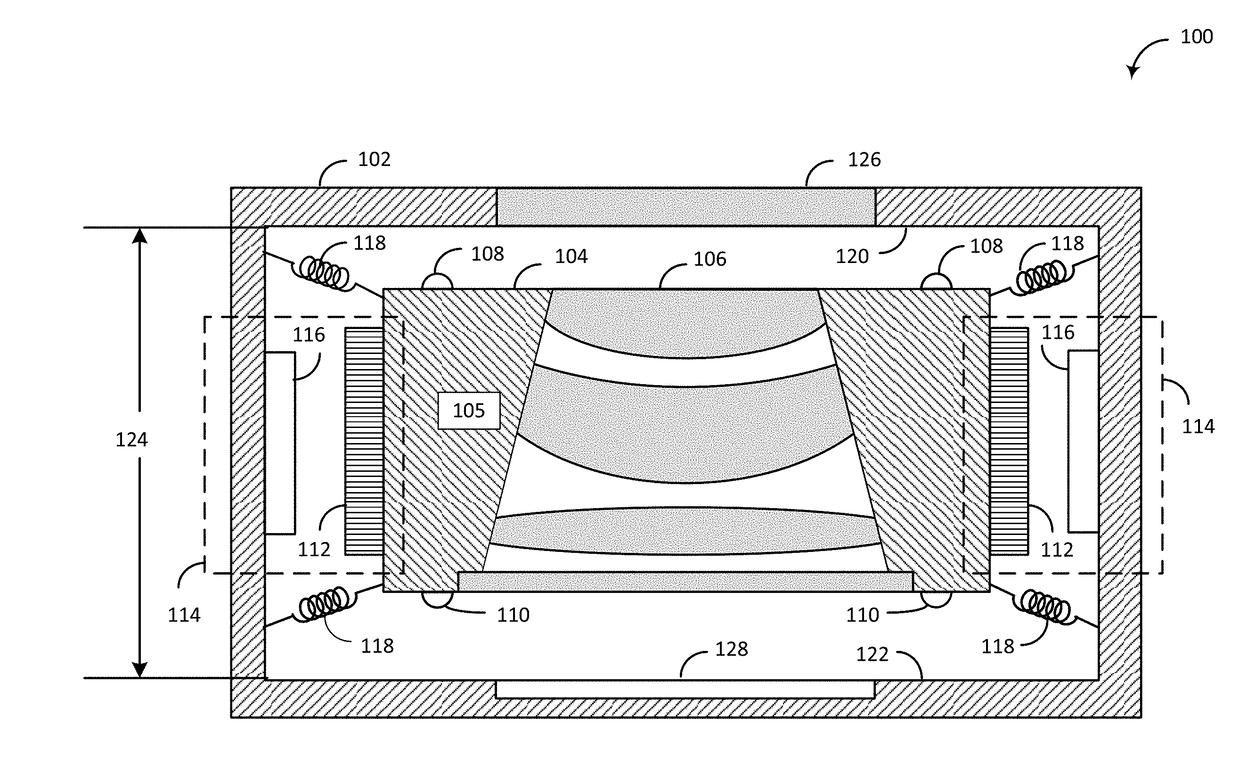

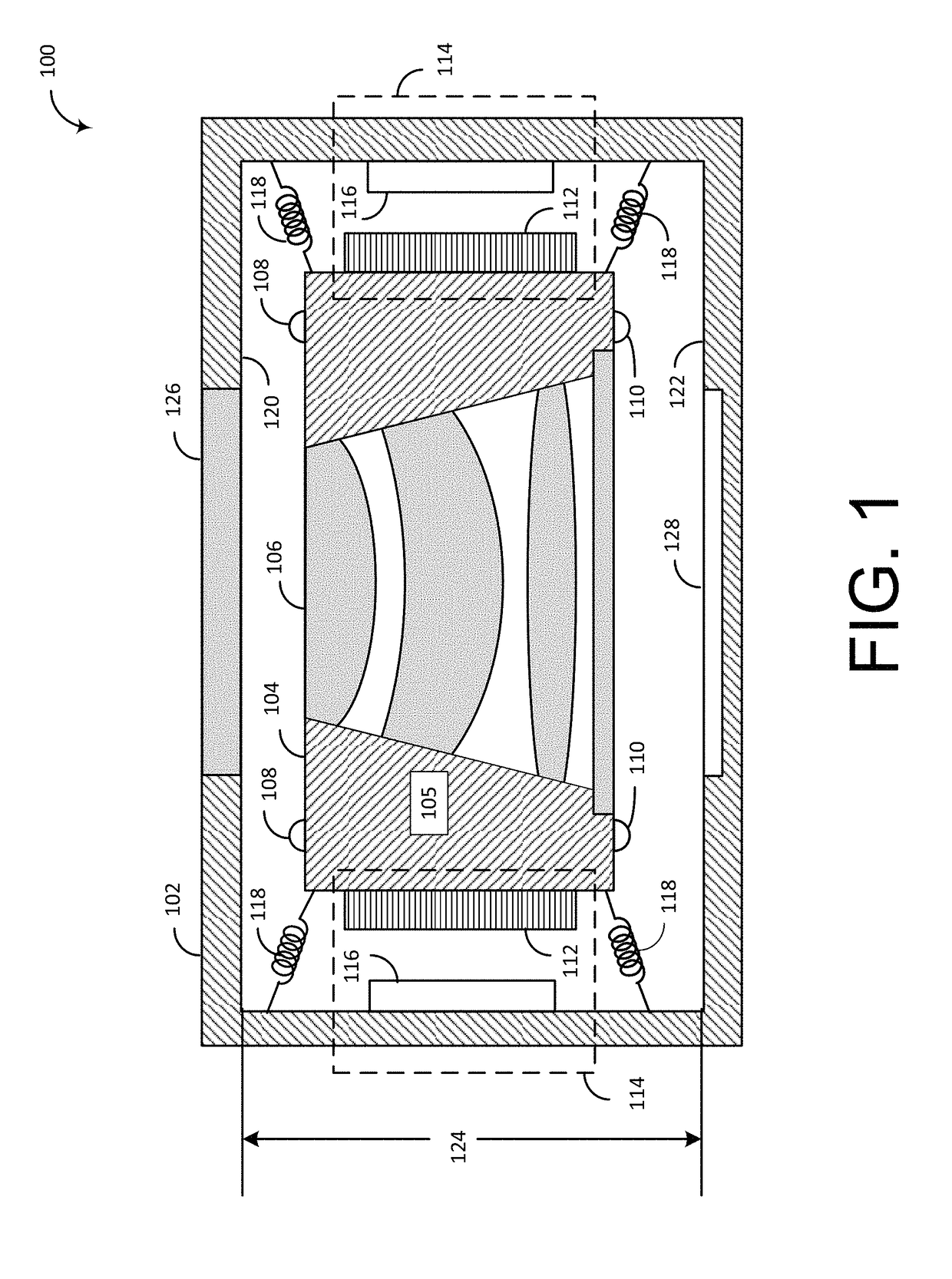

Image

Examples

example clauses

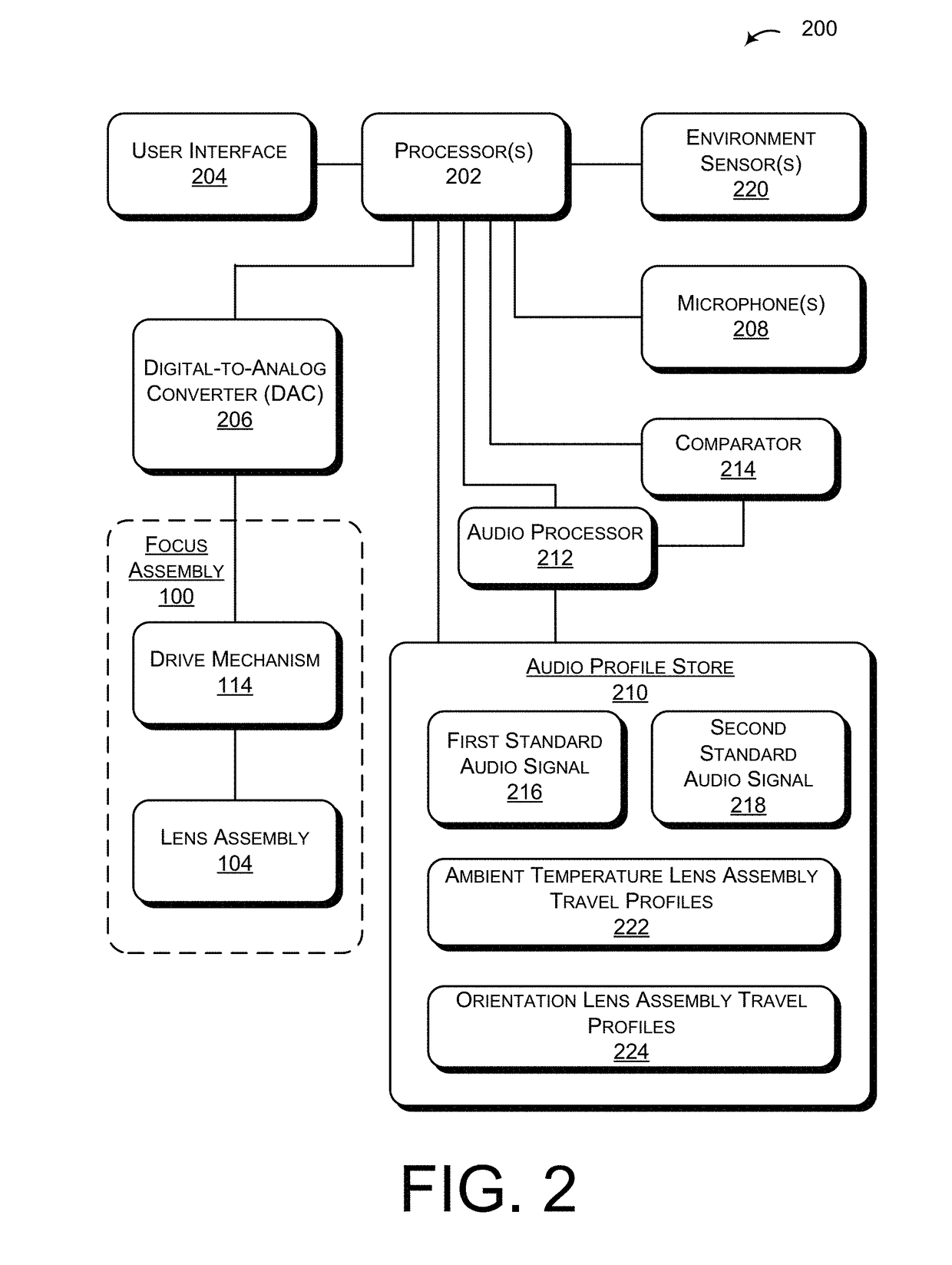

[0046]A. A method of focus calibration in a portable electronic device, the method comprising: receiving an input to activate a camera function of the portable electronic device; moving, by a drive mechanism, a lens assembly of the portable electronic device towards an end of a lens assembly travel; detecting an audio signal associated with the lens assembly reaching the end and recording an end value; and generating a lens assembly travel profile based at least in part on the end value, the lens assembly travel profile indicative of a lens assembly position for focusing.

[0047]B. A method as paragraph A recites, further comprising: activating, upon receiving the input to activate the camera function, one or more microphones of the portable electronic device to detect the audio signal.

[0048]C. A method as paragraph A or B recites, wherein, the value corresponds to an input value to the drive mechanism when the one or more microphones detect the audio signal.

[0049]D. A method as parag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com