Recycled Bottle Cap Blacksplash Assembly and Method for Use

a bottle cap and blacksplash technology, applied in the field of bottle cap backsplash assembly system and method for use, can solve the problems of inconvenient installation, inconvenient installation, and inability to accurately and effectively align the back splash, and achieve the effect of enhancing the overall visual appeal and accurate and effective alignmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The following detailed description is of the best currently contemplated modes of carrying out exemplary embodiments of the present invention. While the specification concludes with claims defining what it is inventor deems as his invention, it is believed that the invention is best understood when taken in conjunction with the drawings and detailed description. Yet, the detailed description is not to be taken in a limiting sense, but rather is made merely for the purpose of illustrating the general principles of the invention, since the scope of the invention is best defined by the appended claims and diagrams. Moreover, the terms and phrases used herein are not intended for the purpose of limiting the invention description, but rather to provide a clear understanding of the invention to allow those who are skilled in the art to make and practice the same.

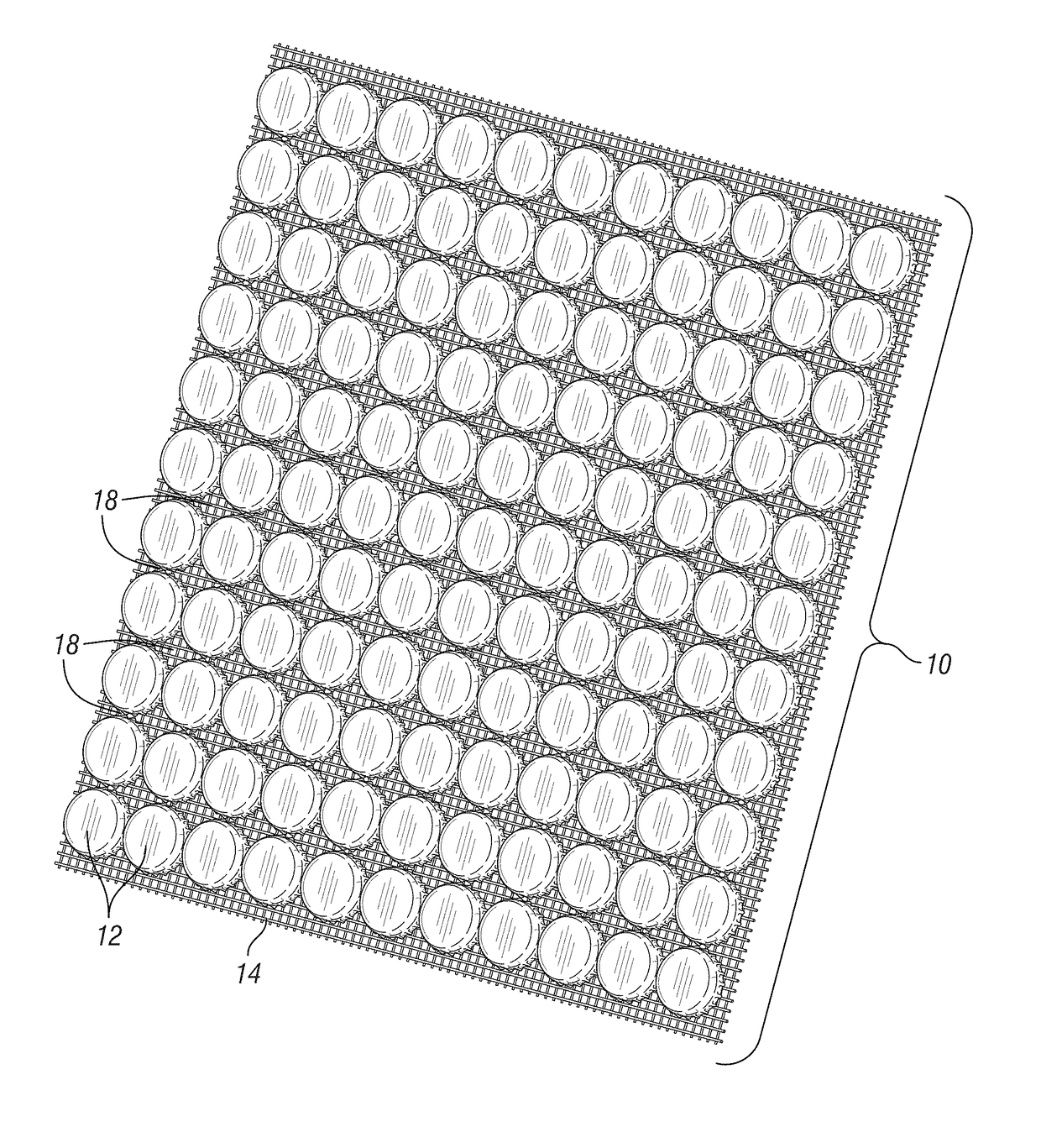

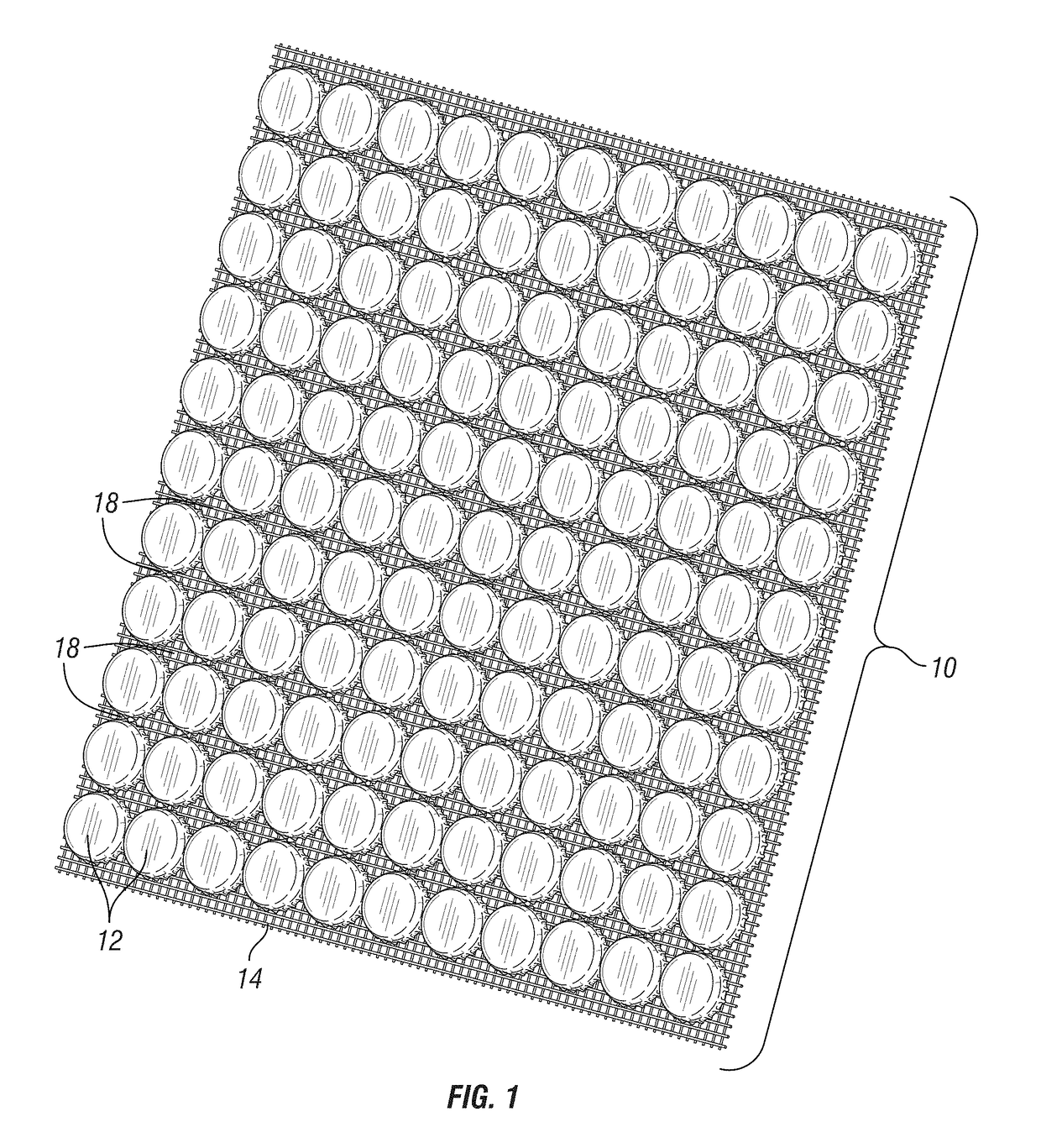

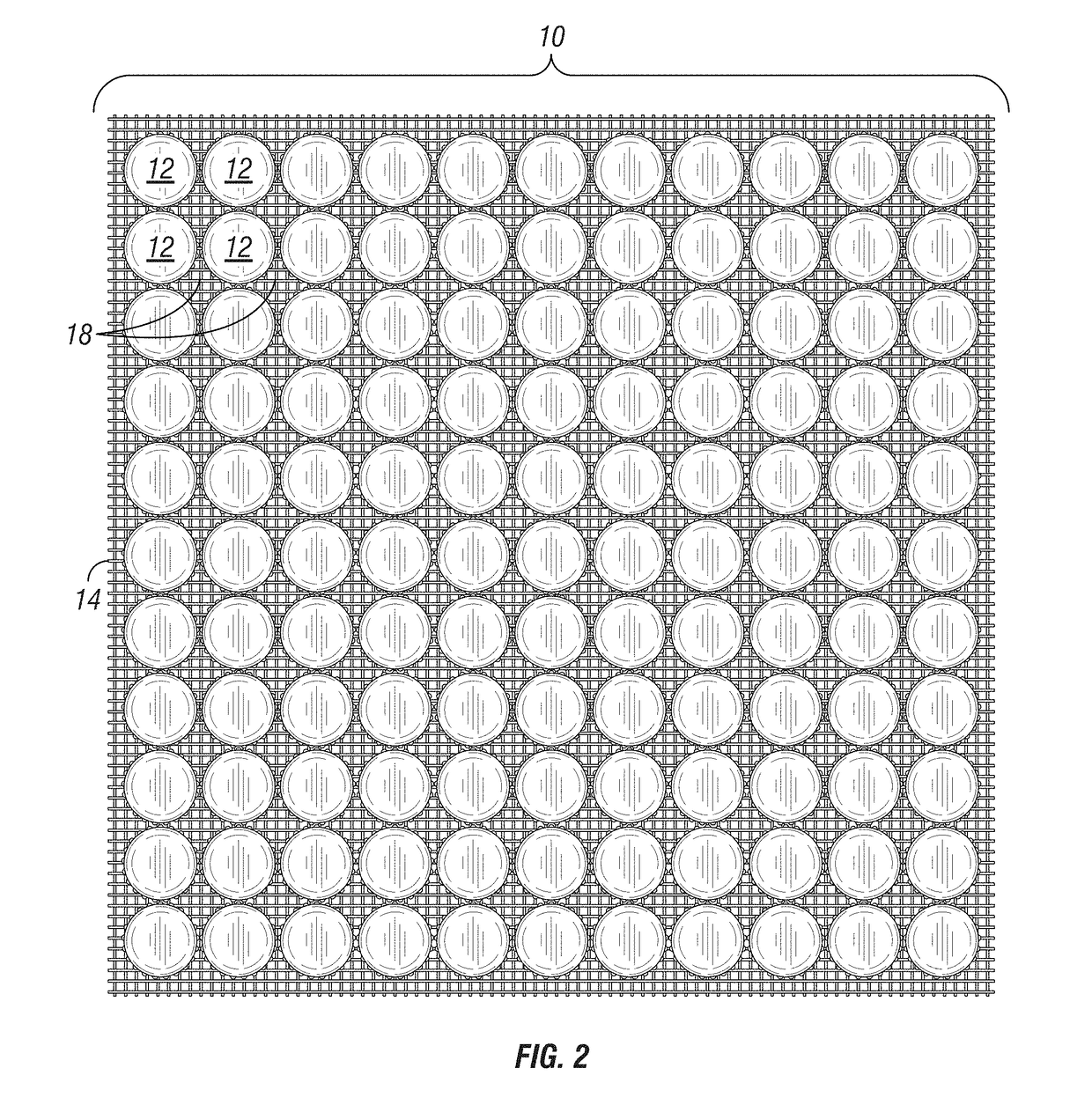

[0029]Broadly, FIG. 1 displays one embodiment of the present invention which provides a bottle cap backsplash assembly 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com