A Protective Glove

a glove and glove technology, applied in the field of protective gloves, can solve the problems of metal lumps in the protective layer in the palm portion closest to the fingers, and achieve the effect of overcompensating the problem of waste of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

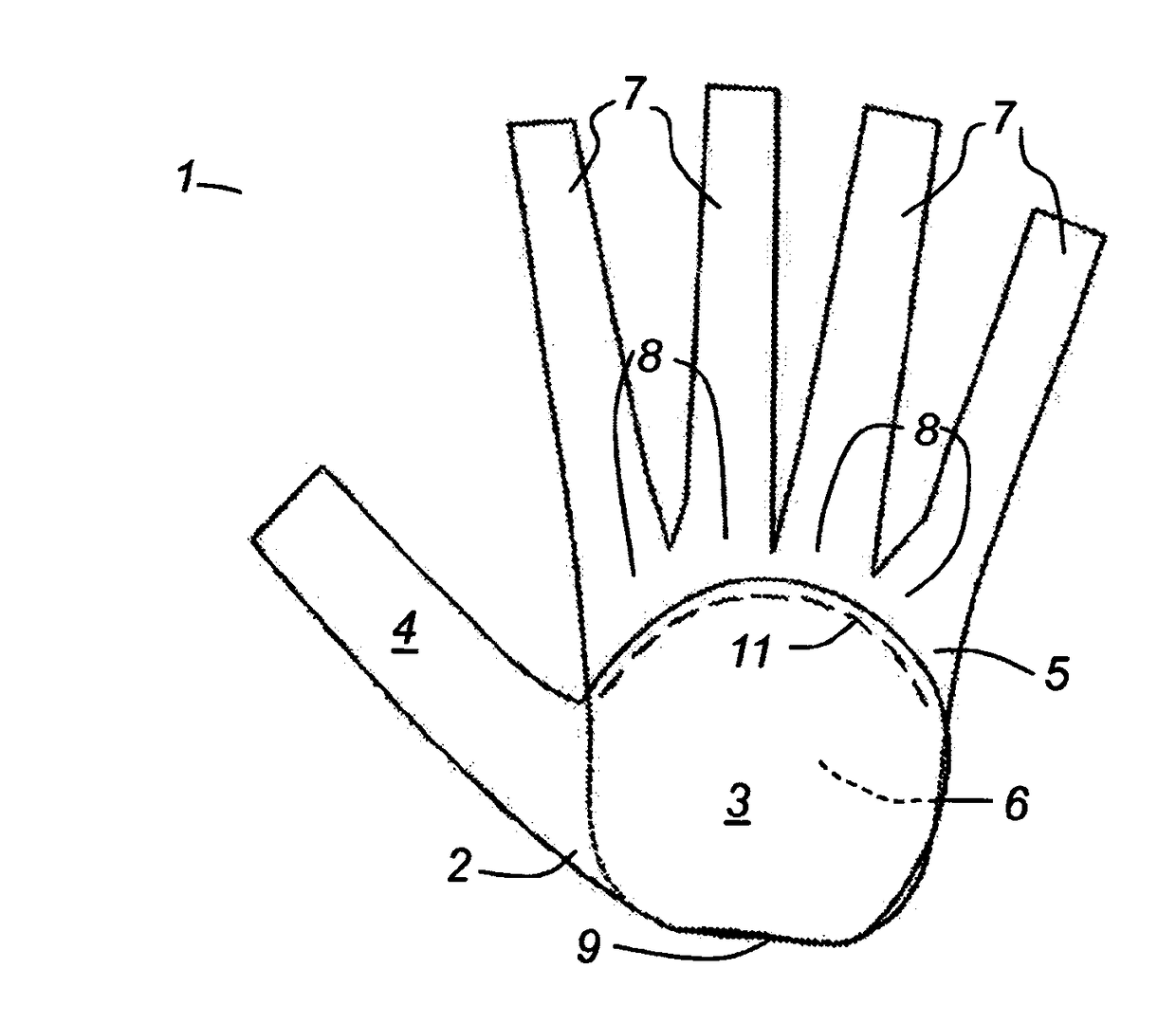

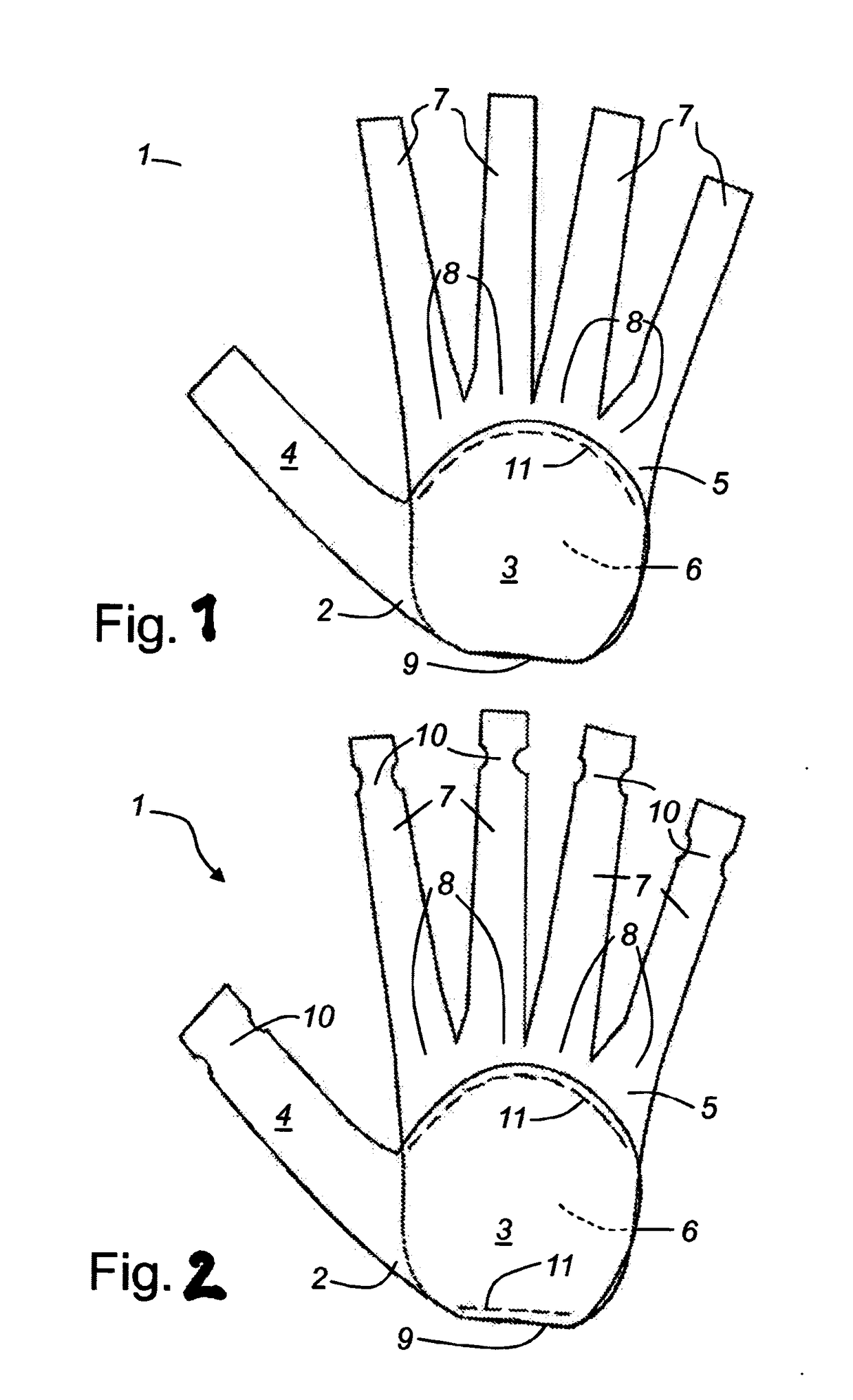

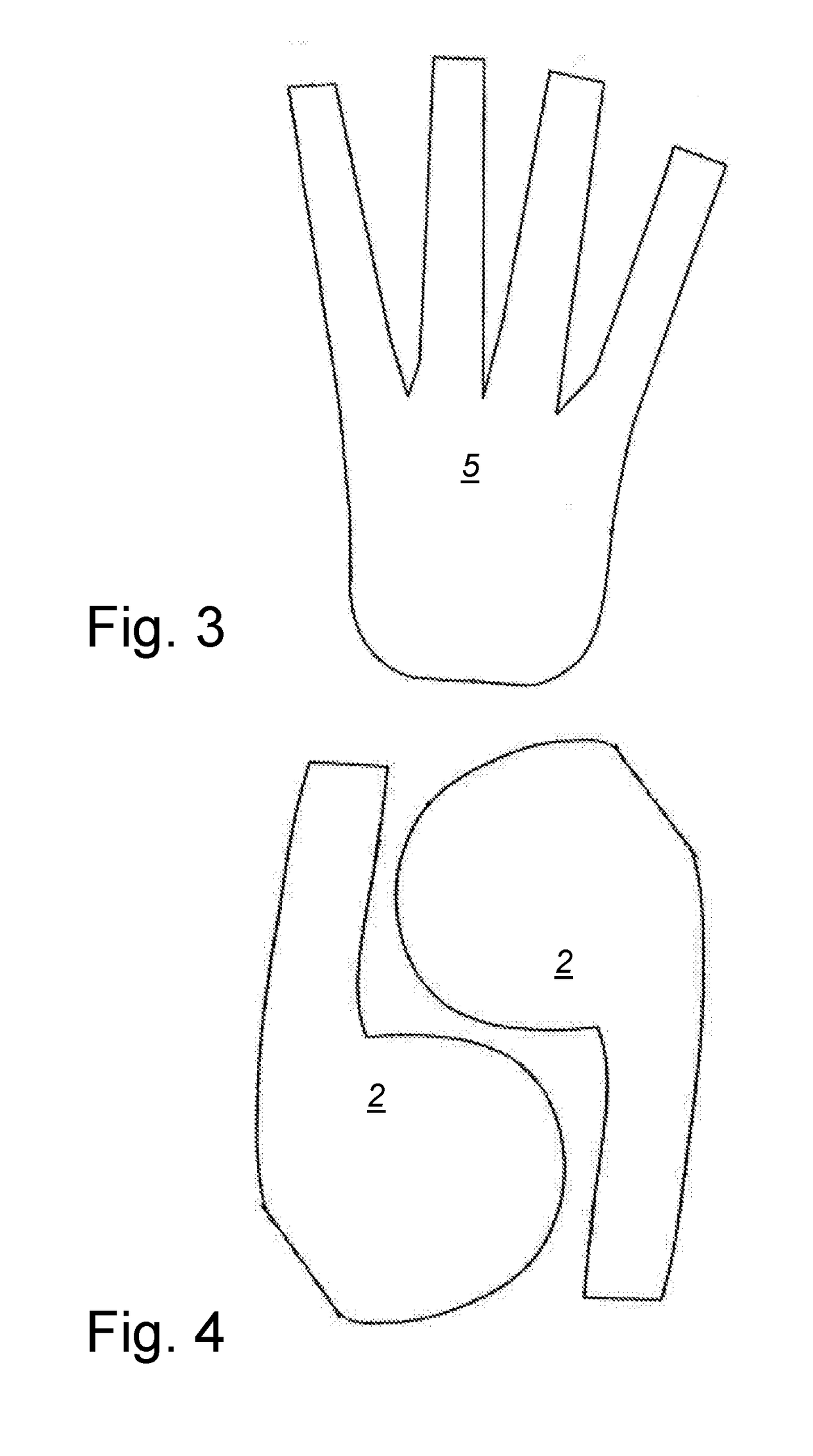

[0029]A protective glove for protection against cuts or puncture wounds according to the present invention comprises an inner layer that is in contact with the hand when the glove is in use, a protective layer 1, see FIG. 1, at least on a part of the palm side of the glove, and an outer layer. The protective layer 1 comprises a composition of a wire mesh of woven metal wires. Further, the protective layer 1 comprises at least two sheets of woven metal, the first sheet 2 of the two sheets has a palm portion 3 and a thumb 4 portion. The second sheet 5 of the two sheets has a palm portion 6 and four finger 7 portions. The two sheets 2, 5 of woven metal are attached to each other with a seam 11 adjacent at least at a part of the line defined by the transition 8 between the fingers 7 and the palm 3, 6.

[0030]In FIG. 2 there is also shown a seam 11 on the palm side 9 close to where the opening of the glove is located. Further, in FIG. 2, the finger 7 and the thumb 4 portions are slightly l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com