Footwear with improved upper

a technology of liquid-impermeable shoes and uppers, which is applied in the direction of uppers, fastenings, bootlegs, etc., can solve the problems of relative complexity of the structure of the shoe having a liquid-impermeable upper, insufficient comfort in the area of the liquid-impermeable shoe according to the prior art, and injuries, etc., to achieve faster and more economical, improve the comfort of the shoe, and optimize the manufacture of the shoe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0031]The first embodiment described below relates, for example, to a flexible shoe for walking on firm ground or in snow. However, the invention is applicable to other fields, such as those mentioned above.

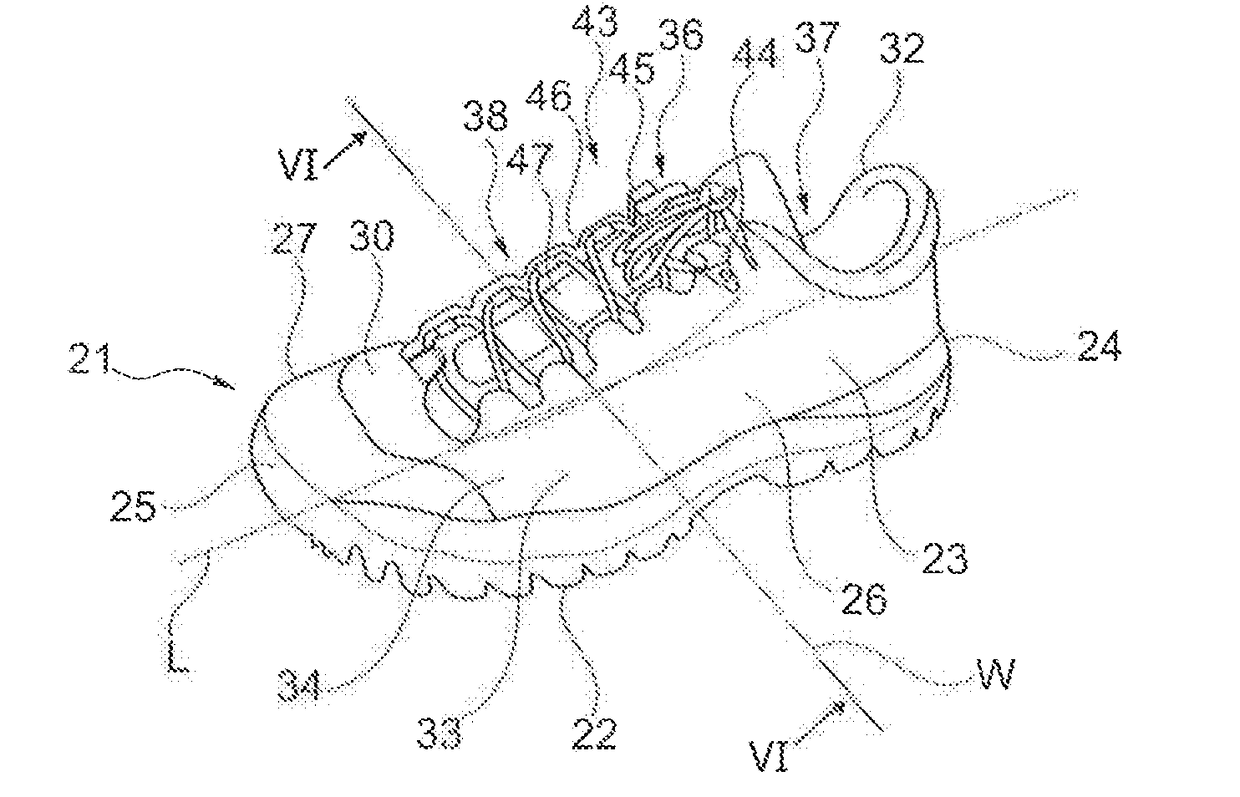

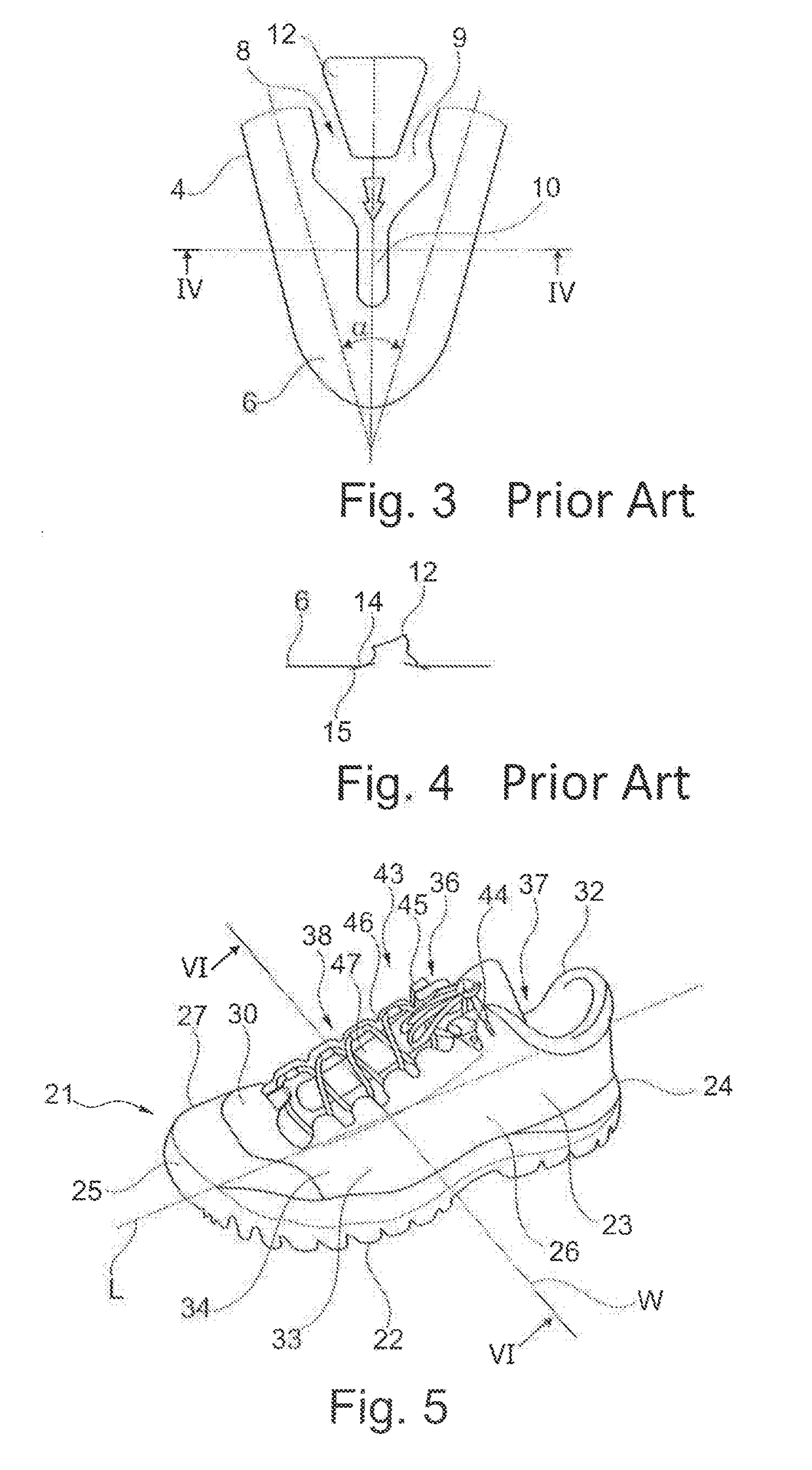

[0032]The first embodiment is described with reference to FIGS. 5 to 8.

[0033]As shown in FIG. 5, a walking shoe 21 is provided to receive the foot of the user. Conventionally, the shoe 21 comprises an outer sole assembly 22 and an upper 23 affixed to the sole assembly. The shoe extends lengthwise, along a longitudinal direction L, from a rear end 24 to a front end 25, and widthwise, along a transverse direction W, between a lateral side 26 and a medial side 27.

[0034]As shown, the upper 23 comprises a lower portion 30, provided to surround the foot, and has no upper portion. However, an upper may alternatively be provided to comprise both a lower portion and an upper portion, the latter being provided to surround the ankle and possibly a portion of the lower leg of the wearer.

[003...

second embodiment

[0051] as can be seen in FIG. 9, the inner layer 35 of the outer shell 33 is an assembly of two portions 61, 62. This configuration makes it possible to optimize the cutting of material for the manufacture of the shoe. More specifically, the scraps of material generated by the cutting of plies are smaller. Given that the price per unit area is very high in the case of a membrane impermeable to water and permeable to gas, the resulting saving is substantial.

[0052]Still for the second embodiment, the portions 61, 62 are assembled with one another to assume the general appearance of the inner layer 35. The assembly is done via a combination of stitching and adhesively affixed strips, which are located in the area of the lateral side 26 and medial side 27 of the shoe 21. This location of seams and strips is outside of the zones of the upper that are subject to bending or to the action of the tightening device. As a result, foot comfort is preserved.

third embodiment

[0053]In the same spirit, as can be seen in FIG. 10, the inner layer 35 of the outer shell 33 is an assembly of three portions 63, 64, 65. Here again, the configuration allows optimizing the cutting of material for the manufacture of the shoe, and the resulting saving is substantial.

[0054]Again, the portions 63, 64, 65 are assembled with one another to assume the general appearance of the inner layer 35. The assembly is done via a combination of stitching and adhesively affixed strips, which are located in the area of the lateral side 26, medial side 27, and rear end 24 of the shoe 21. This location of seams and strips is outside of the zones of the upper that are subject to bending or to the action of the tightening device. As a result, foot comfort is preserved.

[0055]In any case, the invention is made from materials and according to implementation techniques known to one of ordinary skill in the art.

[0056]The invention is not limited to the embodiments described above, and includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opening angle | aaaaa | aaaaa |

| opening angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com