Plastic film applicator with a braking function

a technology of plastic film and applicator, which is applied in the direction of transportation and packaging, thin material processing, and article delivery, etc., can solve the problems of insufficient tension of plastic film extended and affect the wrapping, and achieve the effect of enhancing application convenien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

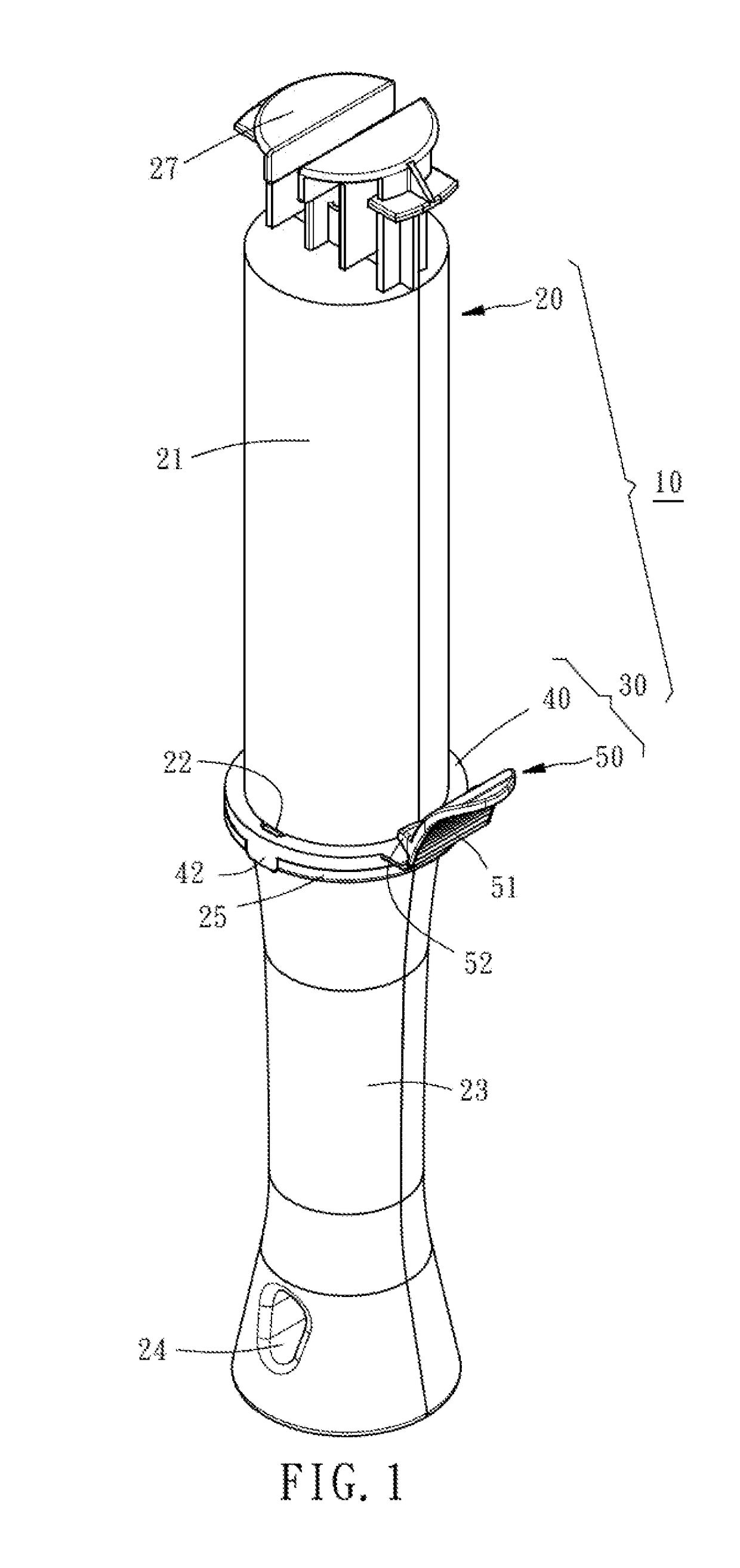

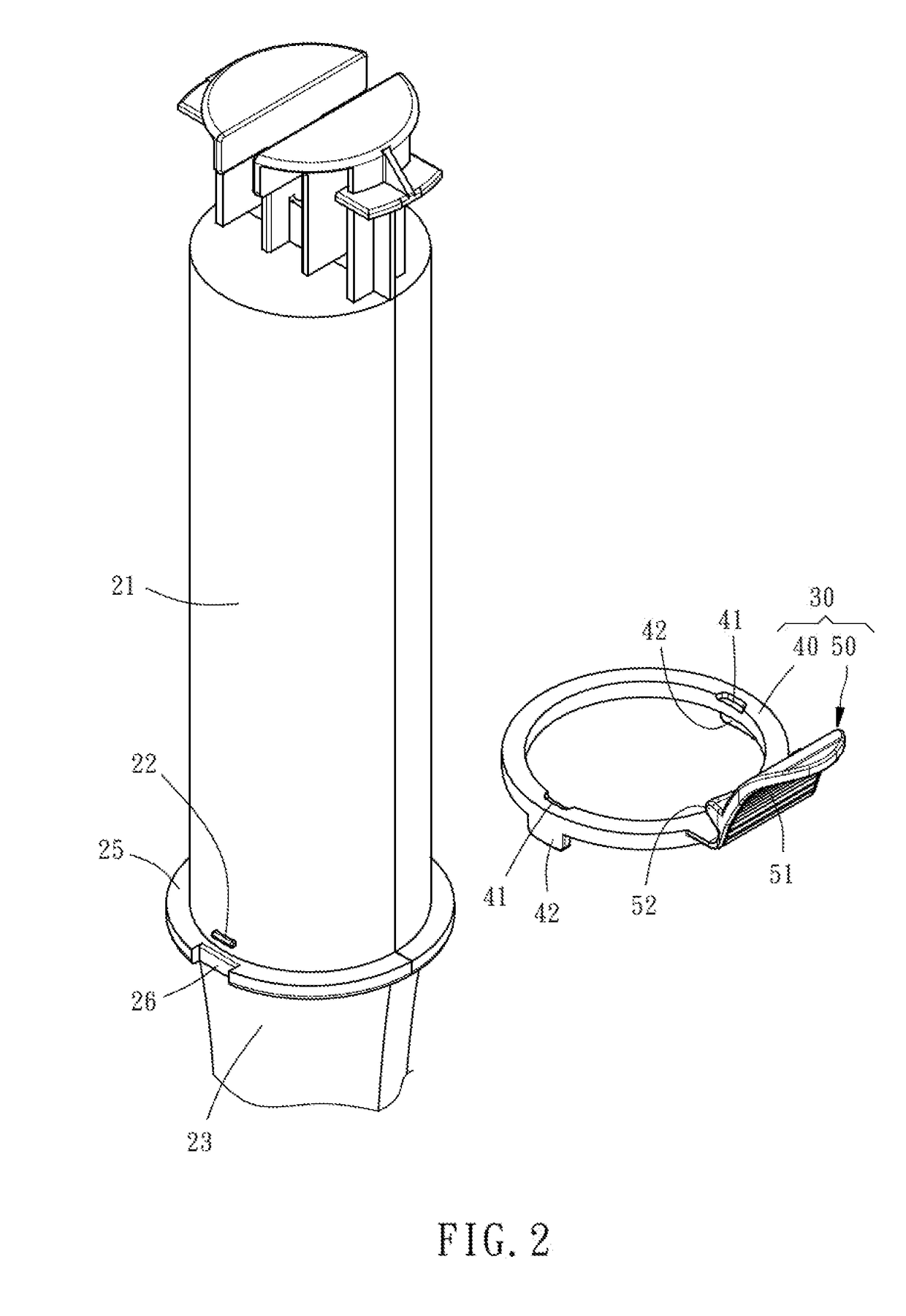

[0018]Referring to FIGS. 1 and 4, a plastic film applicator 10 in accordance with the present invention is shown. The plastic film applicator 10 is configured for the application of a plastic film roll 12. As illustrated, the plastic film roll 12 comprises a film roll shaft 14, and a roll of plastic film 16 wound round the film roll shaft 14. As illustrated in FIGS. 1 and 2, the plastic film applicator 10 comprises an applicator body 20 and a brake device 30.

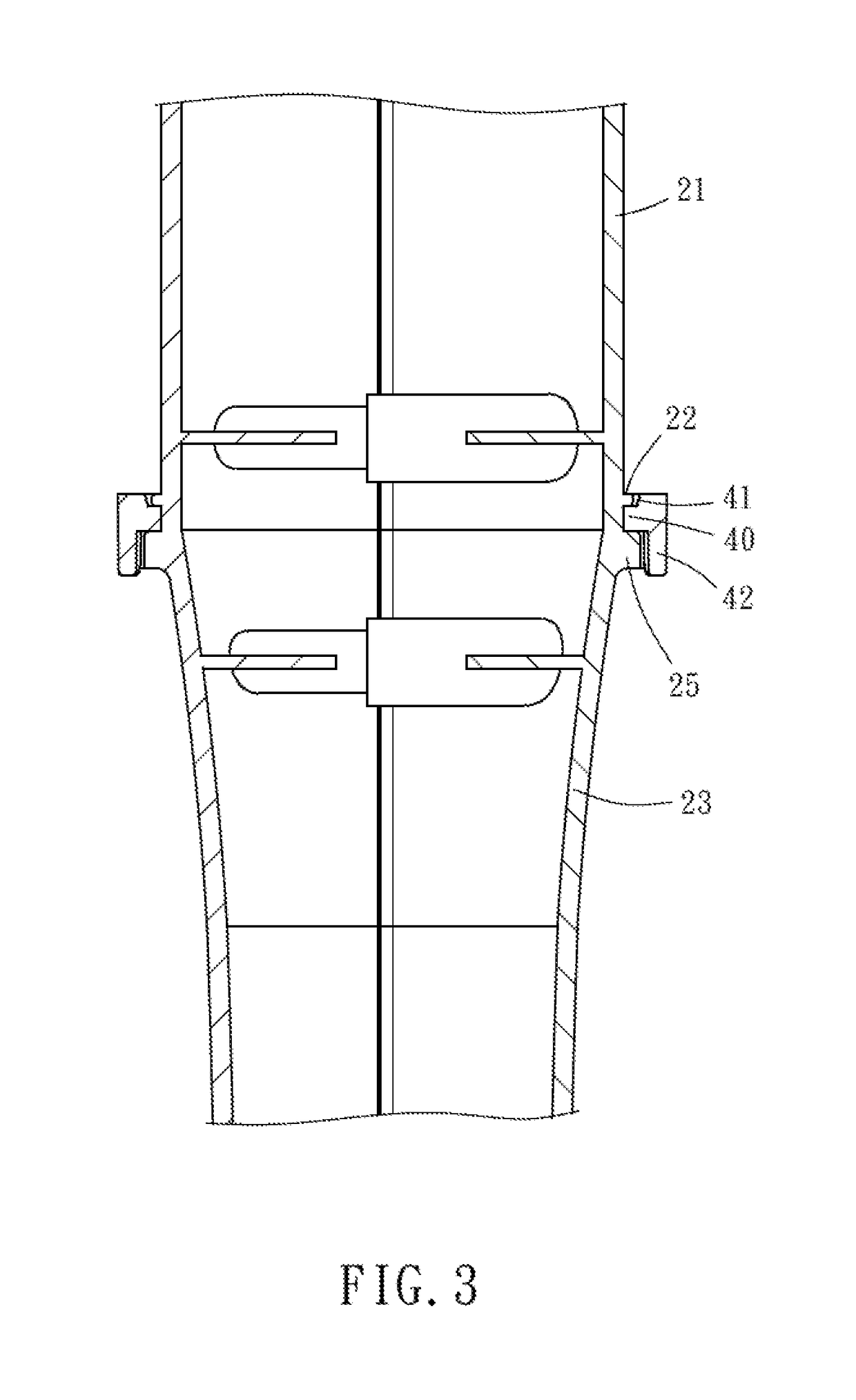

[0019]The applicator body 20 is made of an elastic material (such as, plastics), comprising a mandrel 21, a grip 23 coaxially connected to one end of the mandrel 21, and a flange 25 extended around the periphery of the junction between the mandrel 21 and the grip 23.

[0020]The mandrel 21 has two stopping protrusions 22 located on the outer periphery thereof at two opposite sides. The grip 23 has a hanging hole 24 located at one end thereof remote from the mandrel 21. The flange 25 defines two opposing positioning recesses 26 resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| external force | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com