Fluids for Extreme Pressure and Wear Applications

a technology of fluids and fluids, applied in the direction of lubricant compositions, base materials, additives, etc., can solve the problems of increased workload, and increased workload of submarine propulsion systems. , to achieve the effect of low turnover, substantial effort and expense, and high gear-to-fluid volume interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0062]The following technical reports describe the development of the antioxidant as well as a brief chronological summary of the 2190-S fluid development.

[0063]The research was designed to develop a synthetic alternative to Navy 2190-TEP. A series of synthetic basestocks and mixtures were evaluated, such as polyalphaolefins, alkylated naphthalenes, diesters, polyol esters and polyalkylene glycols, all containing a common commercially available additive package. Lubrizol 857 additive was used, which is recommended at a treat level of 1.4-3.0% in petroleum basestocks to meet the requirements of Navy's MIL-PRF-17331 specification. The research identified 3 candidate fluids that looked promising in most regards, with the exception of rust protection.

[0064]Further research focused on improving the rust protection of the candidate formulations. The Lubrizol 857 package was recommended for use at 1.4-3.0%, and was applied initially at a level of 1.5%. Increasing the concentration of the L...

example 2

Antioxidant Evaluation

[0071]The effectiveness of various antioxidants in the synthetic fluid was evaluated using differential scanning calorimetry (DSC) in accordance with the ASTM D6186 method to measure the oxidation induction time of the fluid formulations. Initially the formulations were tested under conditions of atmospheric pressure and 200° C. Later the test conditions were modified by decreasing the temperature to 180 and increasing pressure to 500 PSI. An iron catalyst was also added to promote oxidation.

[0072]In both sets of tests, formulation BC-7 containing phenylalphanaphthylamine (PAN) and BC-1 containing alkylated phenylalphanaphthylamine (APAN) proved to offer superior oxidation resistance.

TABLE 1Antioxidant Comparison2190-TEPBC-1BC-3BC-4BC-5BC-6BC-7PAO-10 (B)—87.885.885.885.885.885.8PAO-40 (C)—10.012.012.012.012.012.0Durad 620B—1.01.01.01.01.01.0LZ-859—0.10.10.10.10.10.1Irgamet 39—0.10.10.10.10.10.1AntioxidantsNAUGALUBE ®—1.0—————APANVanlube 81——1.0————NAUGALUBE ®——...

example 3

Lubrication Evaluation

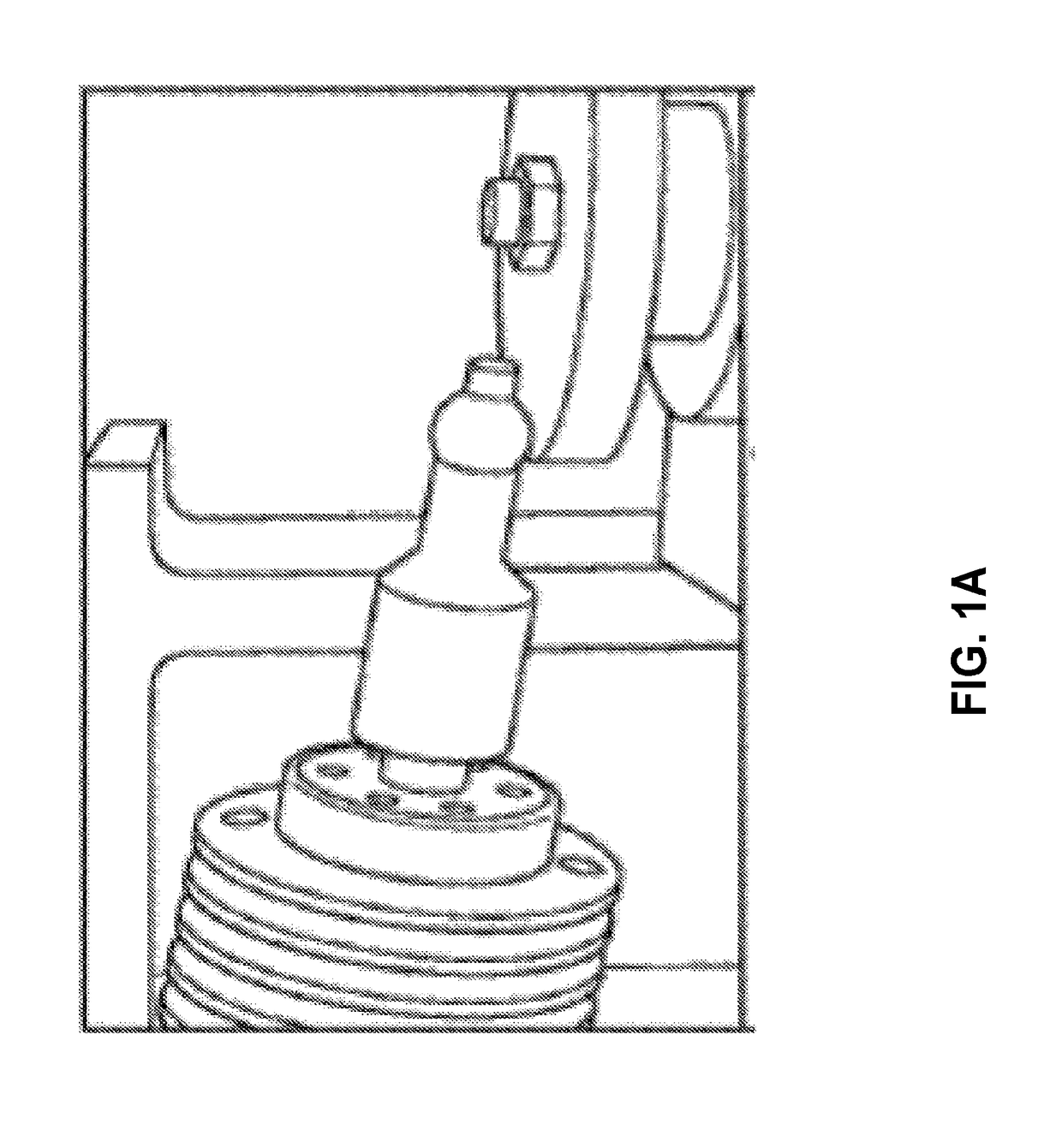

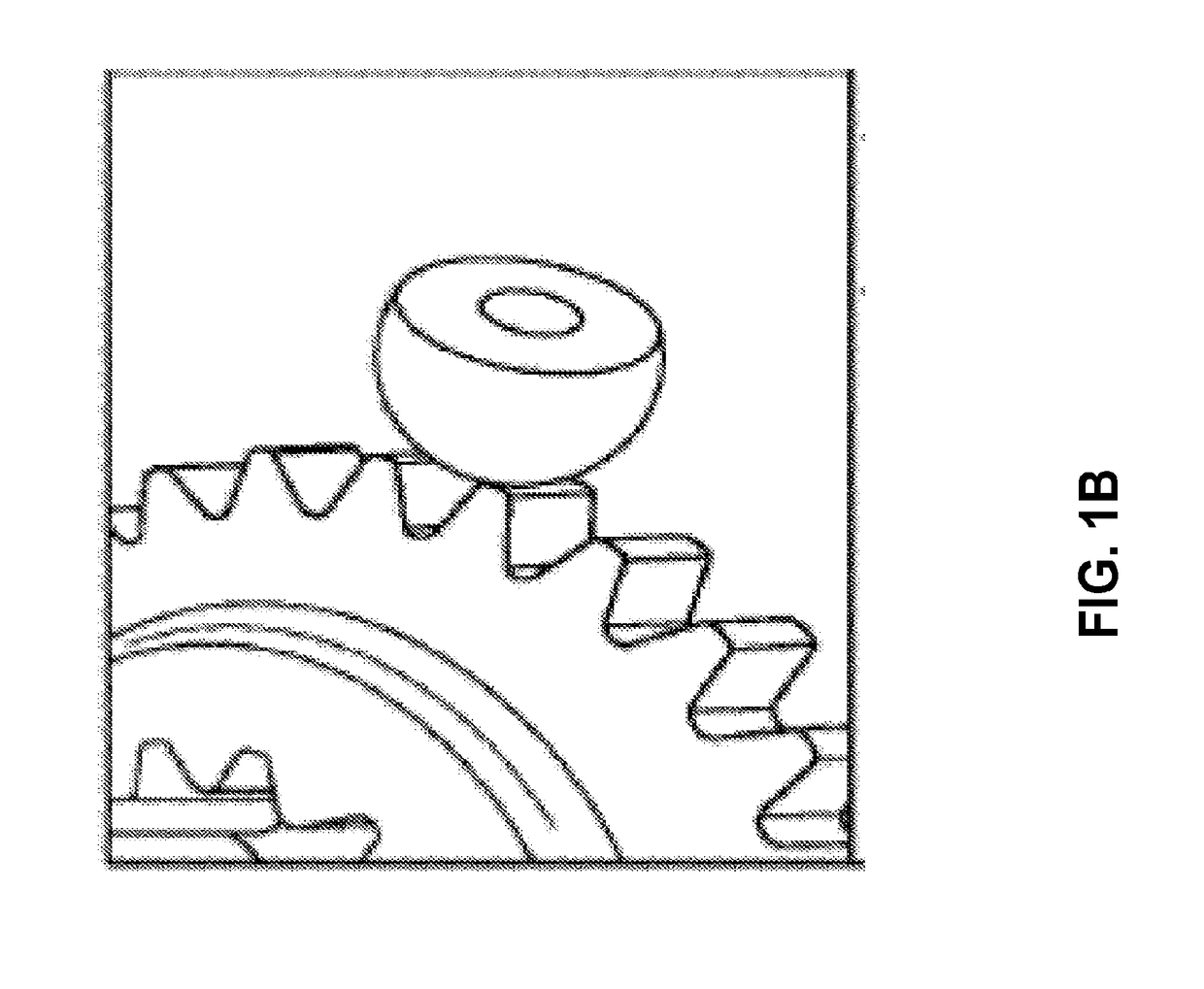

[0074]Rapid and fairly economical tribological test methods that may simulate the sliding friction and forces of gear teeth, such as those developed by Wedeven Associates, use a WAM ball-on-disk machine as shown in FIG. 1. Both the ball and disk are made of AISI 9310 steel typically used for gear applications, and are independently driven so their rotational speeds and contact load can be controlled. The test was actually developed with funding from NAVAIR in an effort to develop an alternative to their Ryder Gear Test Method that has been routinely used to evaluate aviation gearbox and gas turbine engine oils. The lubrication characteristics of the 2190-S fluid were optimized through subjecting a series of formulations for WAM Load Capacity testing.

[0075]Originally, samples of Navy 2190-TEP and the current 2190-S (labeled BC-1A) were tested, along with two additional formulations BC-1A-2 and BC-1A-3. The formulation designated 2190-S (BC-1A) contained 1% Durad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| w/w | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com