Lighting sytems for windows having plastic glazing

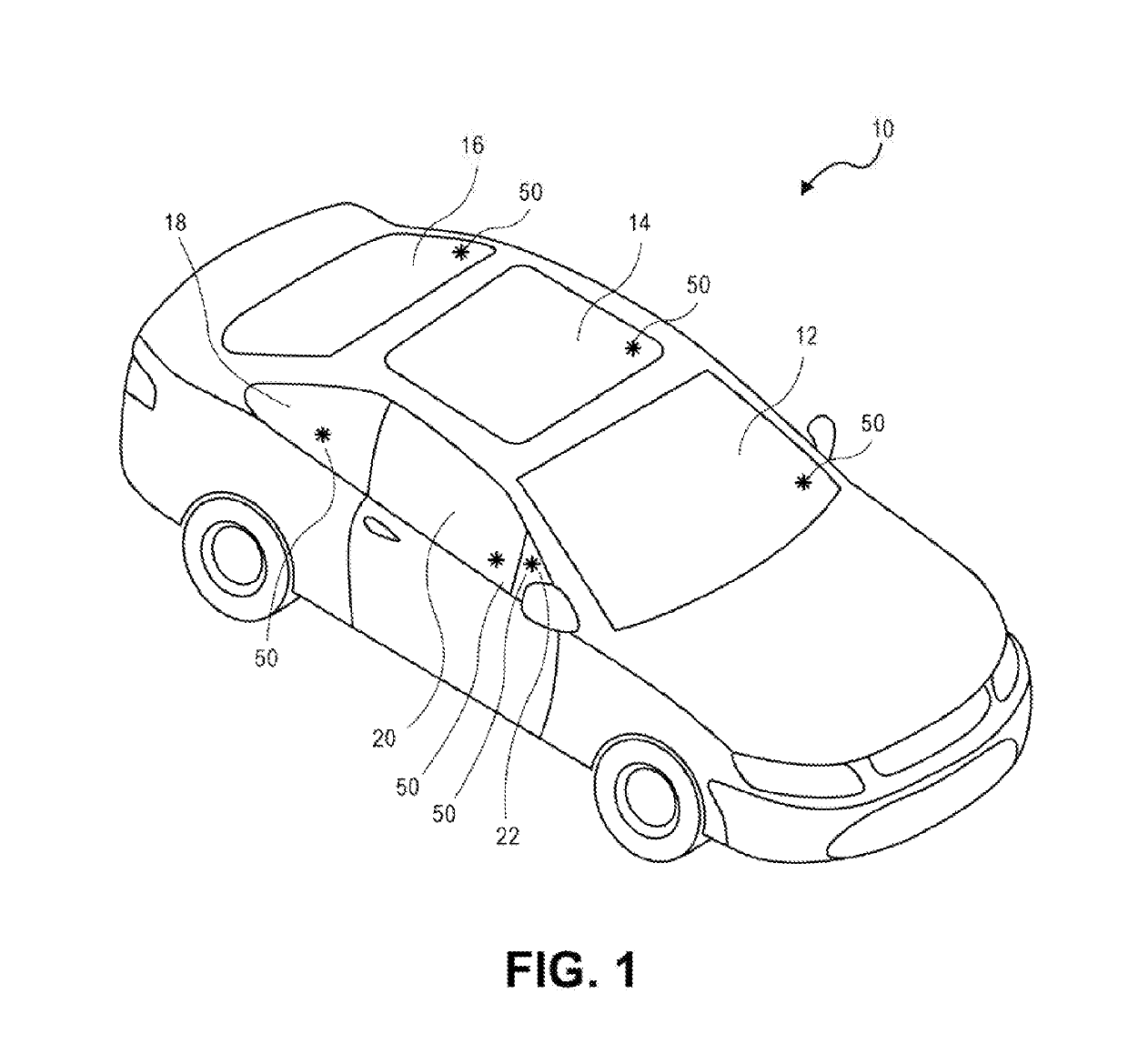

a technology of vehicle windows and light systems, which is applied in vehicle spotlighting, other compartment lighting, instruments, etc., can solve the problems of adding to the overall weight of the vehicle, adding to the cost and complexity of assembling the vehicle, and adding to the overall complexity and cost of manufacturing and assembling the vehicl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0058]The plastic glazing of example 1, wherein the light unit is supported on at least one of the following: the first vehicle window glazing component and the second vehicle window glazing component, wherein the window comprises at least one of the following: a front window, a side window, a rear quarter window, a rear window, a front quarter window, and a panoramic window.

example 3

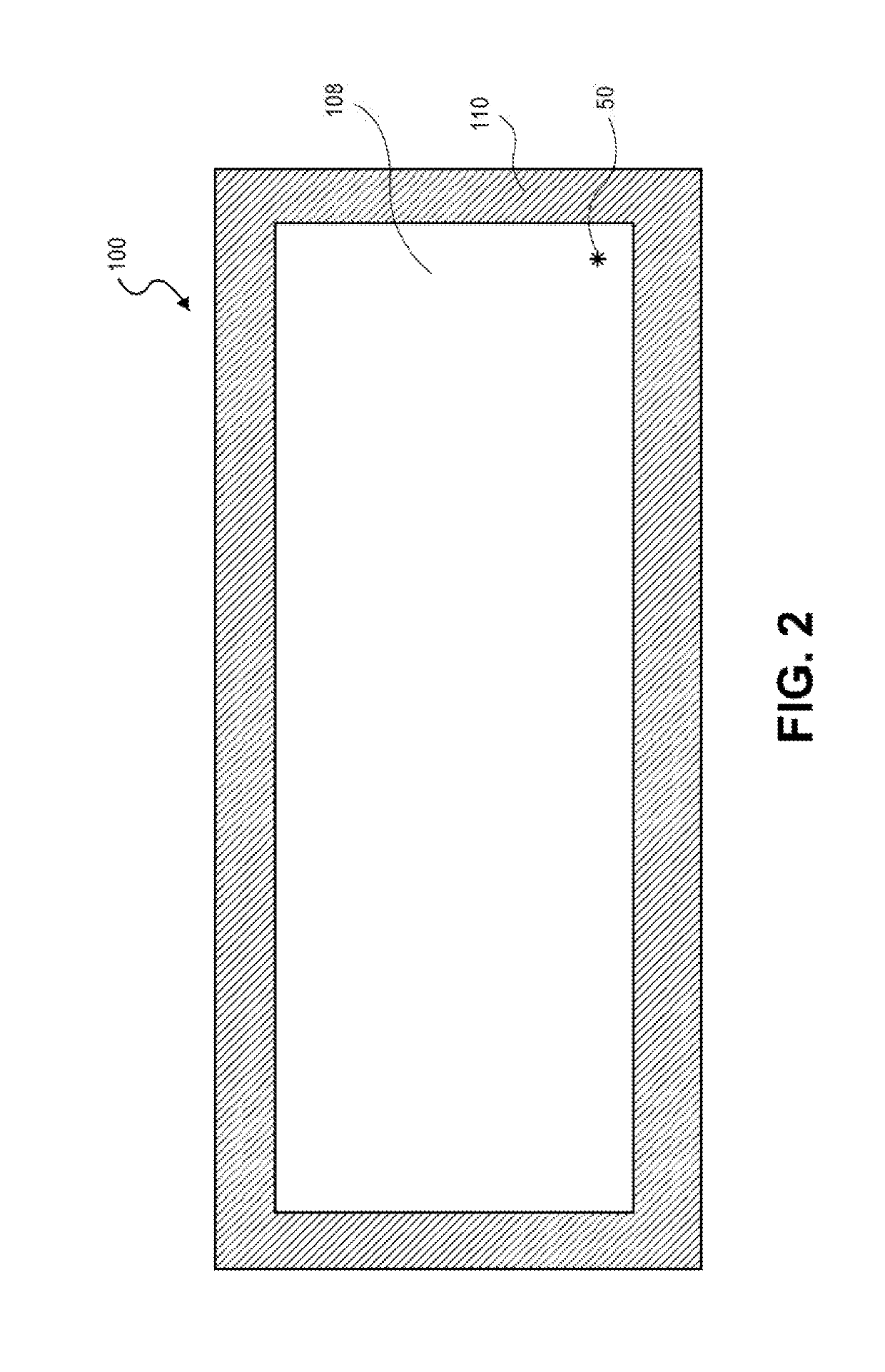

[0059]The plastic glazing of any one of Examples 1-2, wherein the plastic glazing is attached to a housing unit that is configured to support the light unit, wherein the housing unit comprises a fiber-reinforced polymer.

example 4

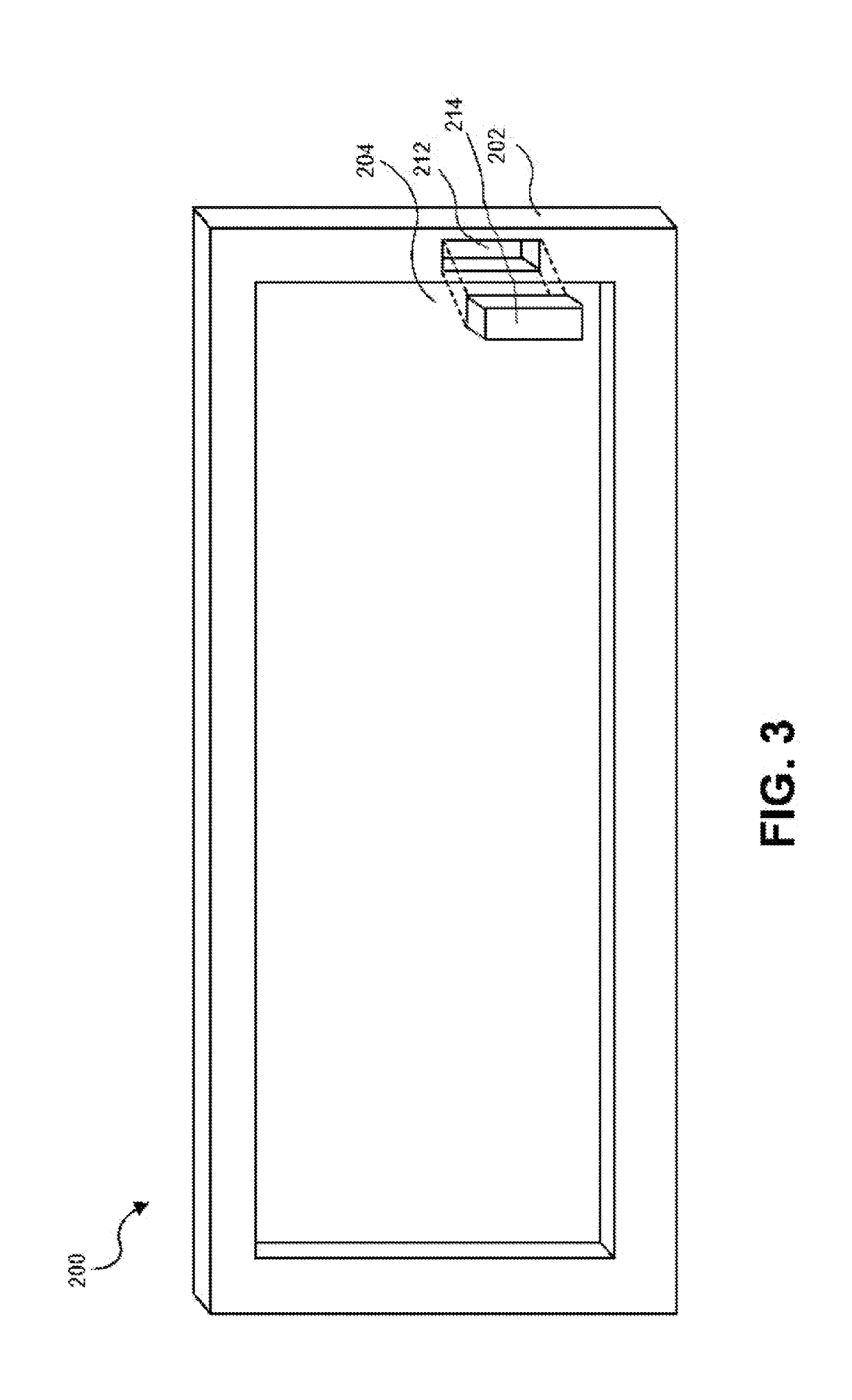

[0060]The plastic glazing of any one of Examples 1-3, further comprising a light guide configured to receive the light from the light unit, wherein the light guide is configured to one of the following: emit the received light along a length thereof to provide the light feature, deliver the light to an end thereof to provide the light feature internally within the vehicle, and deliver the light to an end thereof to provide the light feature externally from the vehicle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com