Composition for Manufacturing Secondary Battery Separator and Secondary Battery Including the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0038]Hereinafter, constitution and function of the present disclosure will be described in more detail through preferable exemplary embodiments of the present disclosure. It is to be noted that Examples to be described below are provided merely for specifically exemplifying the present disclosure, and accordingly, the present disclosure is not limited to the following Examples.

[0039]Descriptions which are not described in the specification can be sufficiently and technically deduced by a person skilled in the technical field, and accordingly, details thereof will be omitted.

[0040]1. Preparation of Composition for Manufacturing Secondary Battery Separator

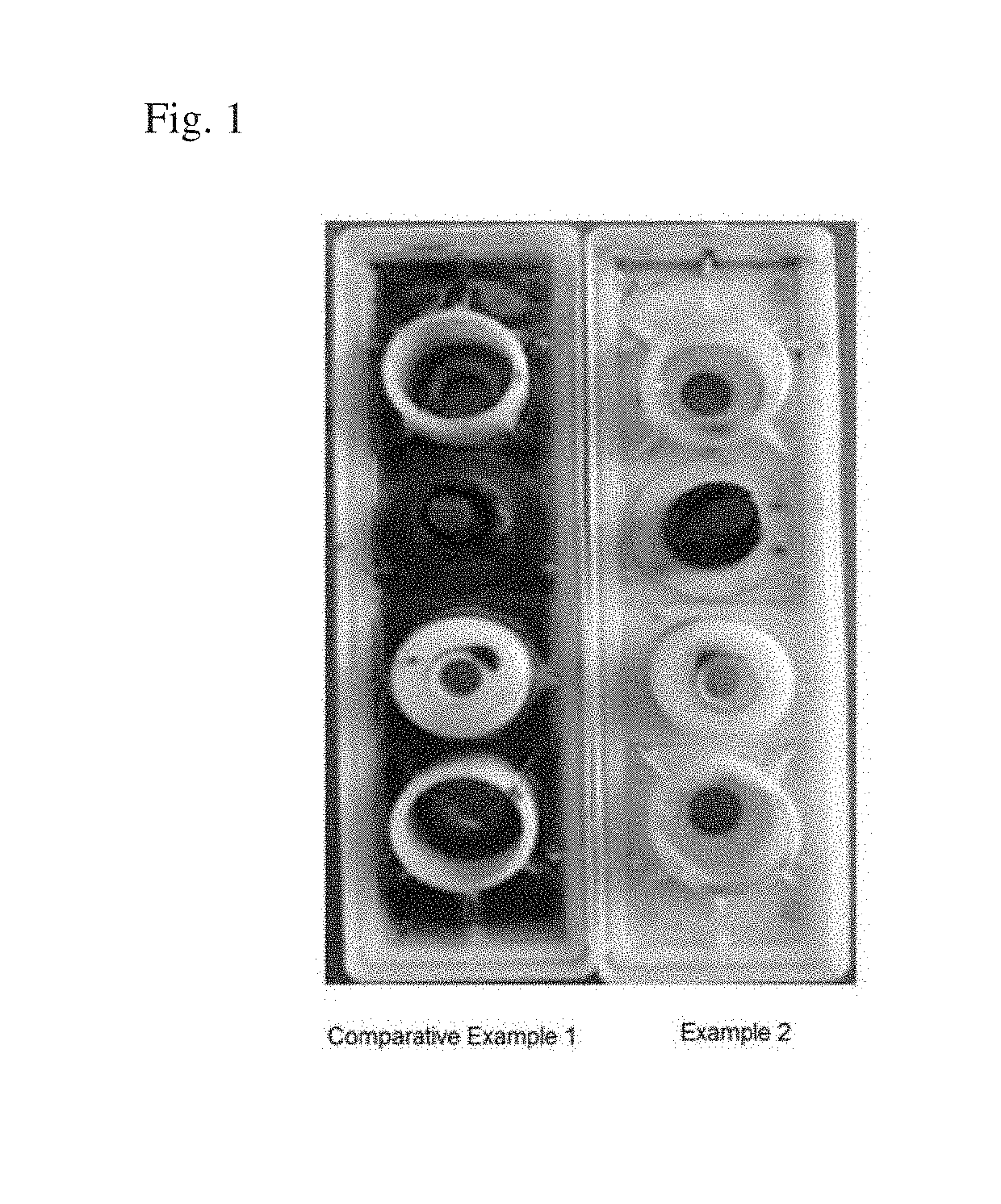

[0041]Compositions for manufacturing secondary battery separators according to Examples 1 to 23 and Comparative Examples 1 to 24 were prepared with the compositions shown in Tables 1 to 3.

TABLE 1(Unit: wt %)ClassificationExample 1Example 2Example 3Example 4Example 5Example 6Example 7Example 8Polyethylene20.020.020.020.020.020.020.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap