Noise reducing silencer with a spirally shaped tube for a compressor

a compressor and spiral tube technology, applied in the field of compressors, can solve the problems of reducing the efficiency of the compressor, noise generated at noise emitted from the air inlet or suction side of the reciprocating compressor, etc., to reduce the restriction of the inlet air flow, reduce the cost, and eliminate the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The present invention will be described with respect to particular embodiments and with reference to certain drawings but the invention is not limited thereto and can be combined interchangeably with certain features in the different embodiments.

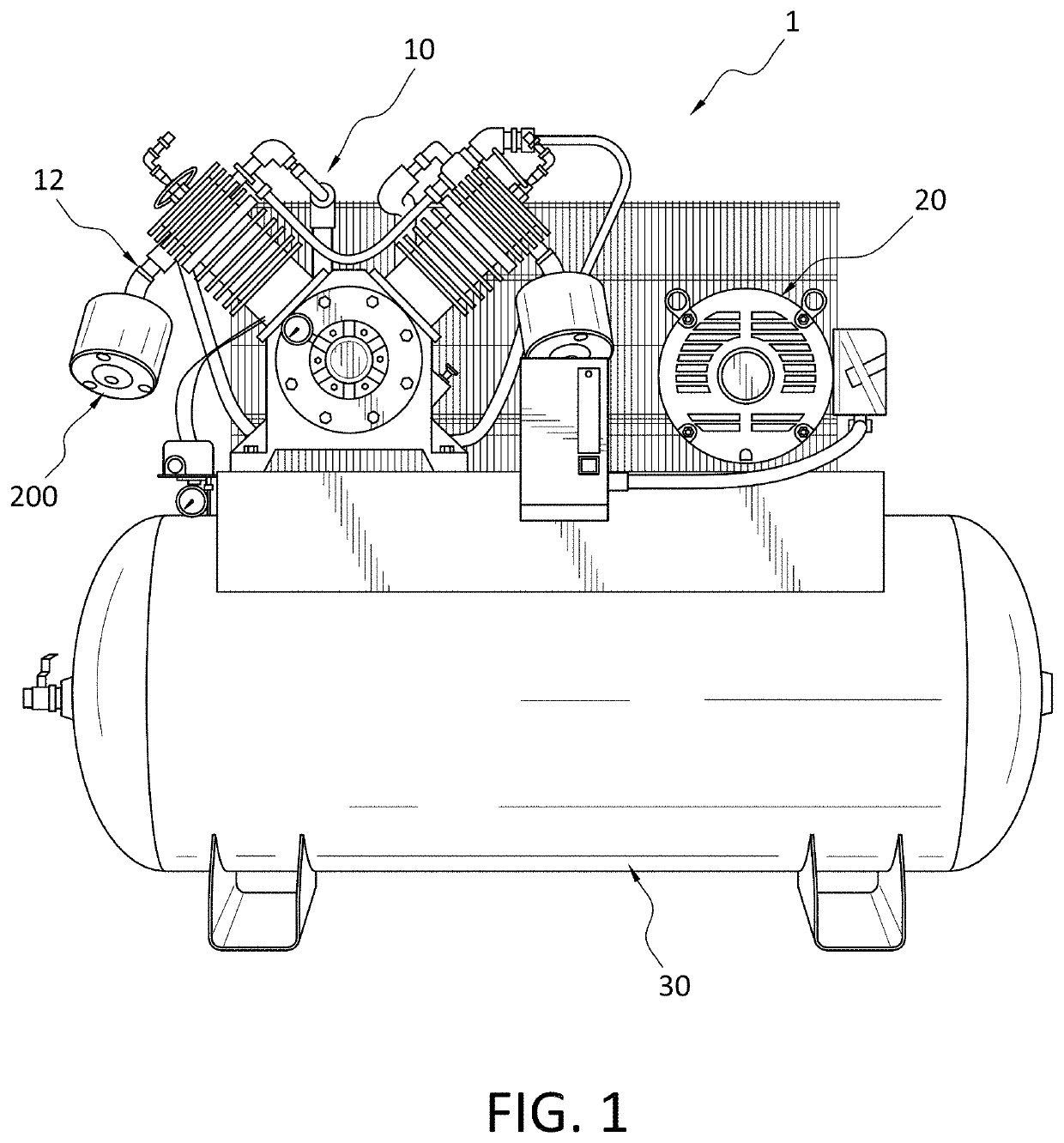

[0016]FIG. 1 illustrates a compressor installation, which can be a single or two stage reciprocating compressor or piston compressor, a centrifugal compressor, a scroll compressor, a screw compressor having male and female compressor elements, or the like, that includes a noise reducing silencer 200 according to the present invention. In this embodiment, the compressor element 10 is illustrated as a reciprocating compressor having at least two piston cylinders, preferably four piston cylinders and up to ten piston cylinders, for compressing air received from an air inlet 12 of the compressor element 10. The noise reducing silencer 200 is provided at the air inlet 12 for filtering the inlet air. The compressor element 10 is driven by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com