Pittsburgh hand tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

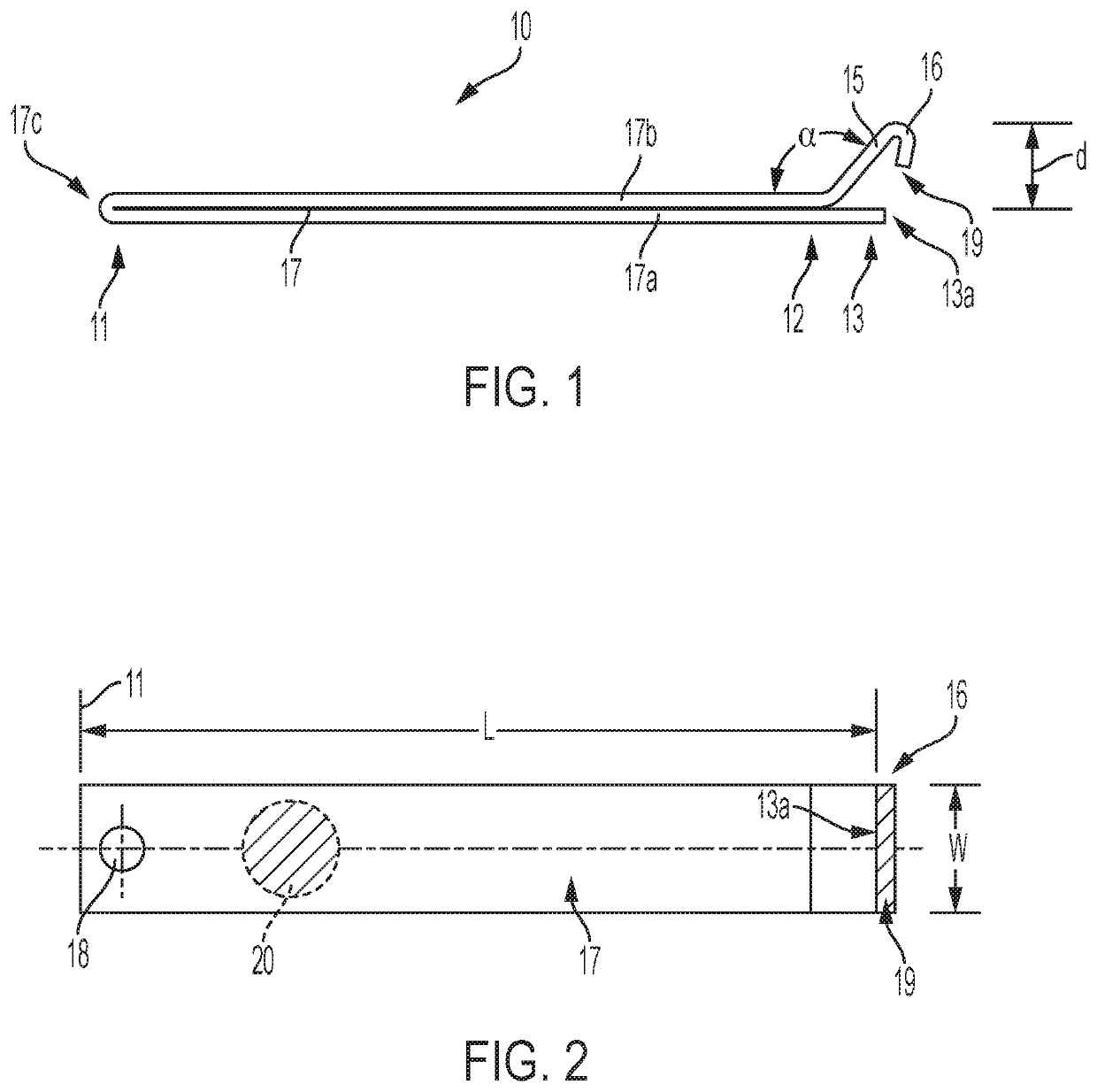

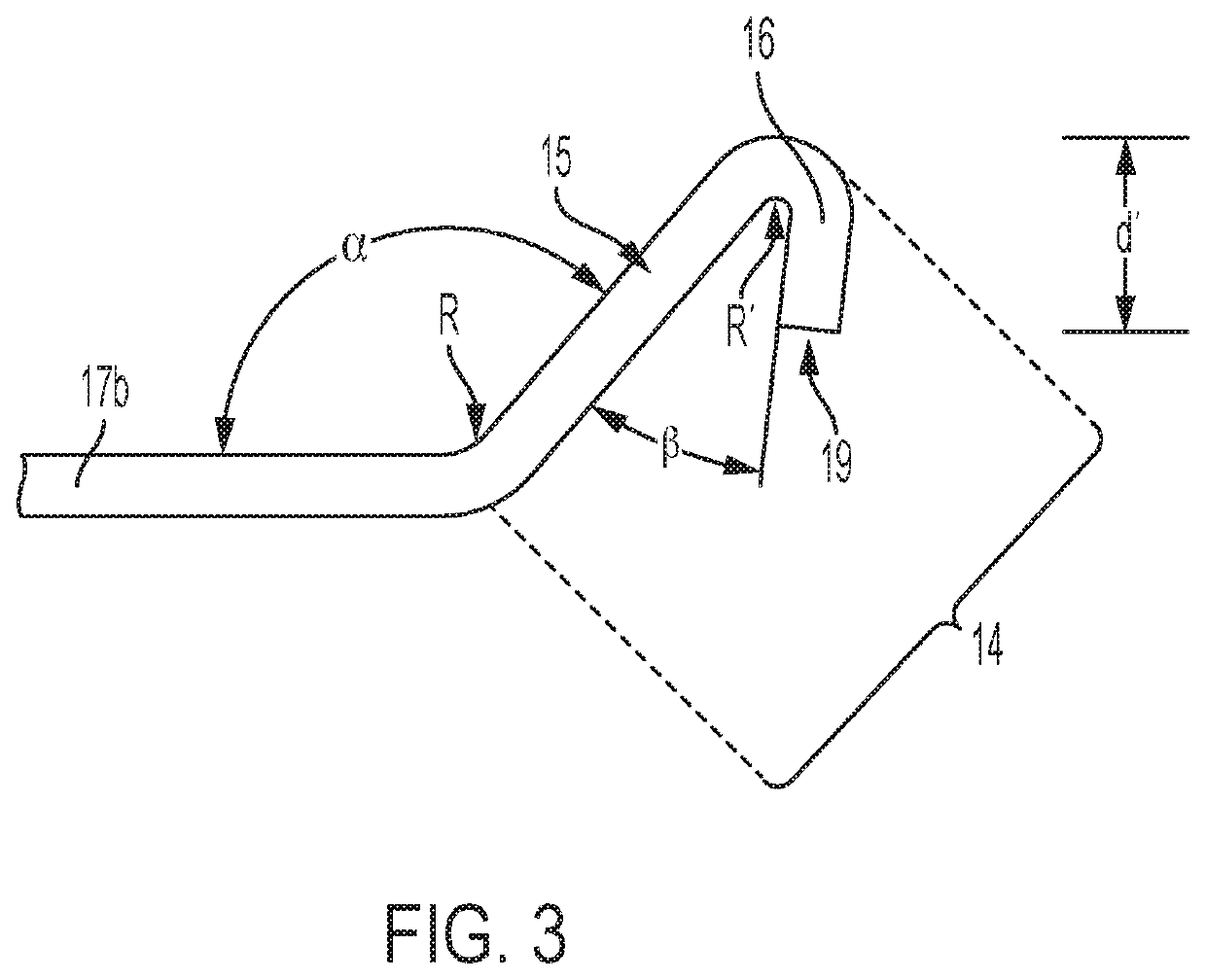

[0007]The description herein is made with reference to the Figures. This is for purposes of convenience only and is not restrictive or limiting to the scope of the disclosure and the practice thereof.

[0008]Referring to FIG. 1, depicted thereat is a cross-sectional view of an embodiment of the tool of the disclosure. As shown in this particular embodiment, tool 10 comprised of elongated handle portion 17. In one practice, elongated handle portion 17 is a rigid, flat, and substantially planar, substantially rectangular handle portion comprised of, without limitation, metal (e.g. cold-rolled steel), plastic, glass-filled nylon and like materials as known in the art for sheet metal tooling. In the embodiment depicted at FIG. 1, the handle portion 17 extends from a first end, generally shown at 12, to a second end, generally shown at 11. The first end 12 comprises two prongs, 13 and 14. First prong 13 extends in an outward direction from handle portion 17 and lies in substantially the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com