Molded manufacturing for modular furniture

a technology of modular furniture and manufacturing methods, applied in the direction of convertible stools, bedstools, chairs, etc., can solve the problems of production errors and high manufacturing costs, and achieve the effect of convenient interchangeability and convenient transportation and storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The manufacturing process of modular furniture can be time consuming complex and unreliable when a large number of parts are required. When many pieces need to be combined, a significant number of man hours must be spent assembling the furniture piece and checking quality to ensure proper assembly.

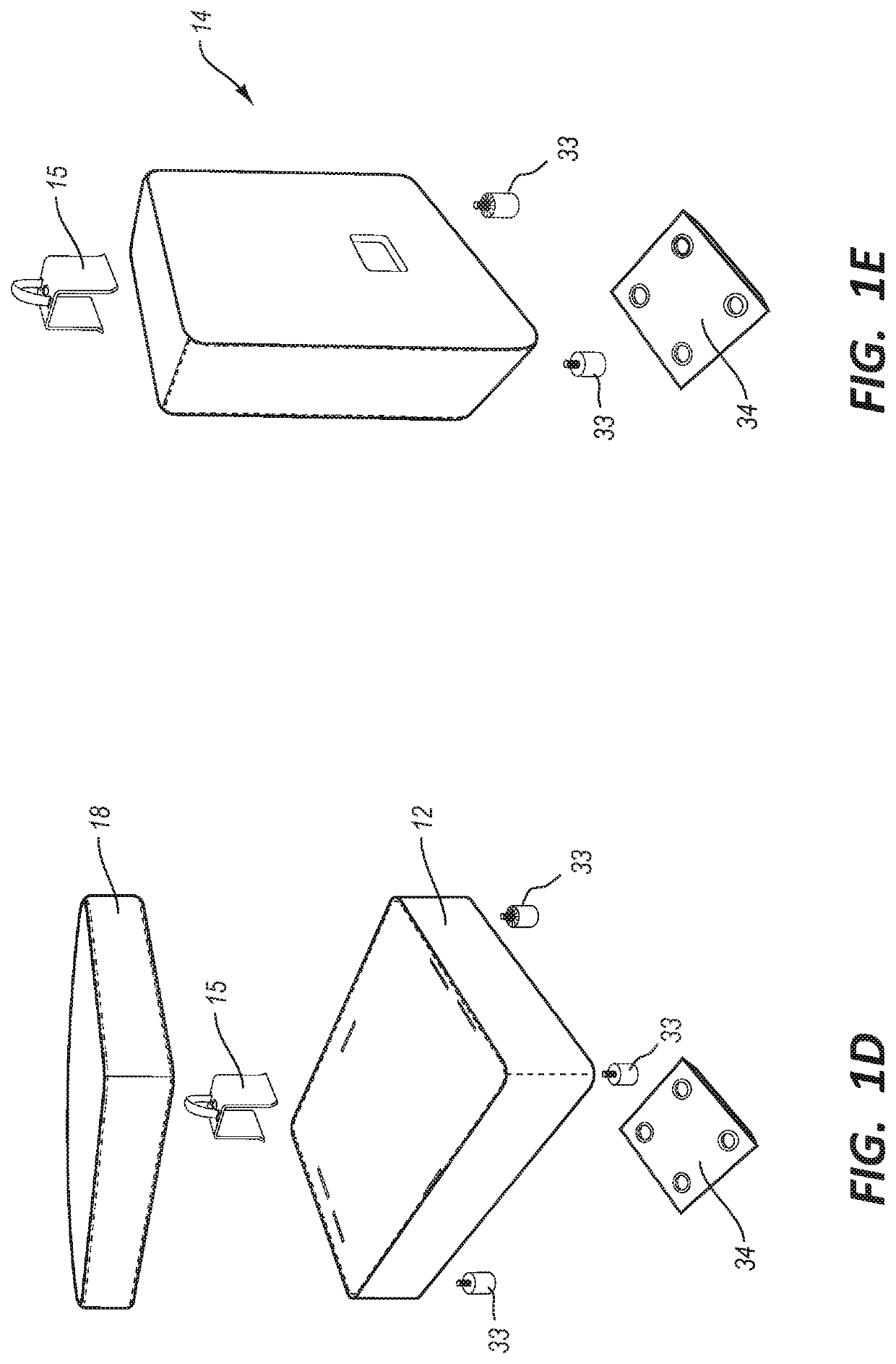

[0028]The apparatus and manufacturing methods disclosed herein provide a streamlined, simplified method of manufacturing modular furniture components. In particular, the methods described herein require minimal assembly, which lessens manufacturing time and cost. For example, manufacturing methods according to the present disclosure reduce the number of components needed to form a modular furniture base or transverse structure, thus reducing the labor associated with assembly thereof, as well as reducing quality assurance and other costly processes.

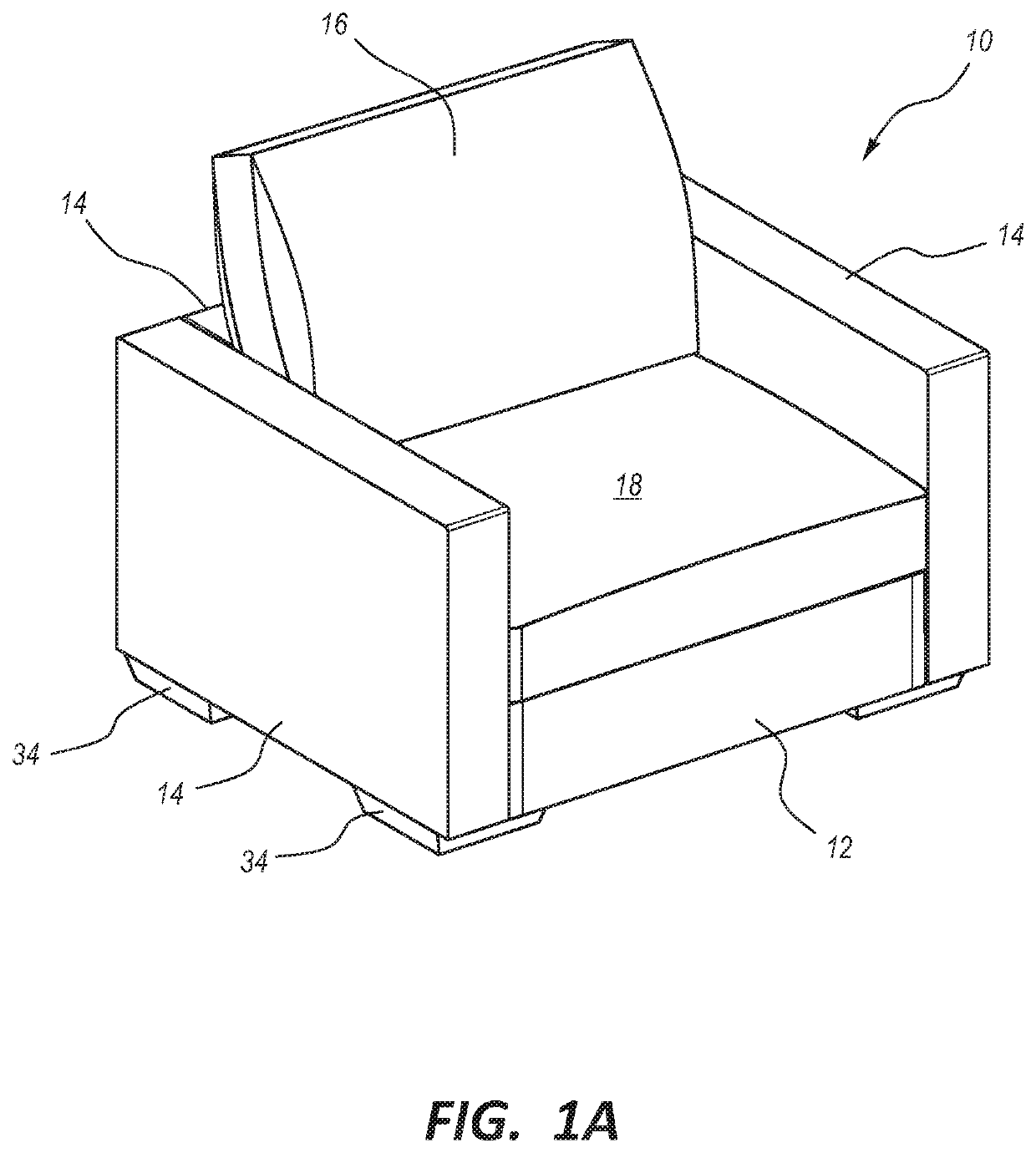

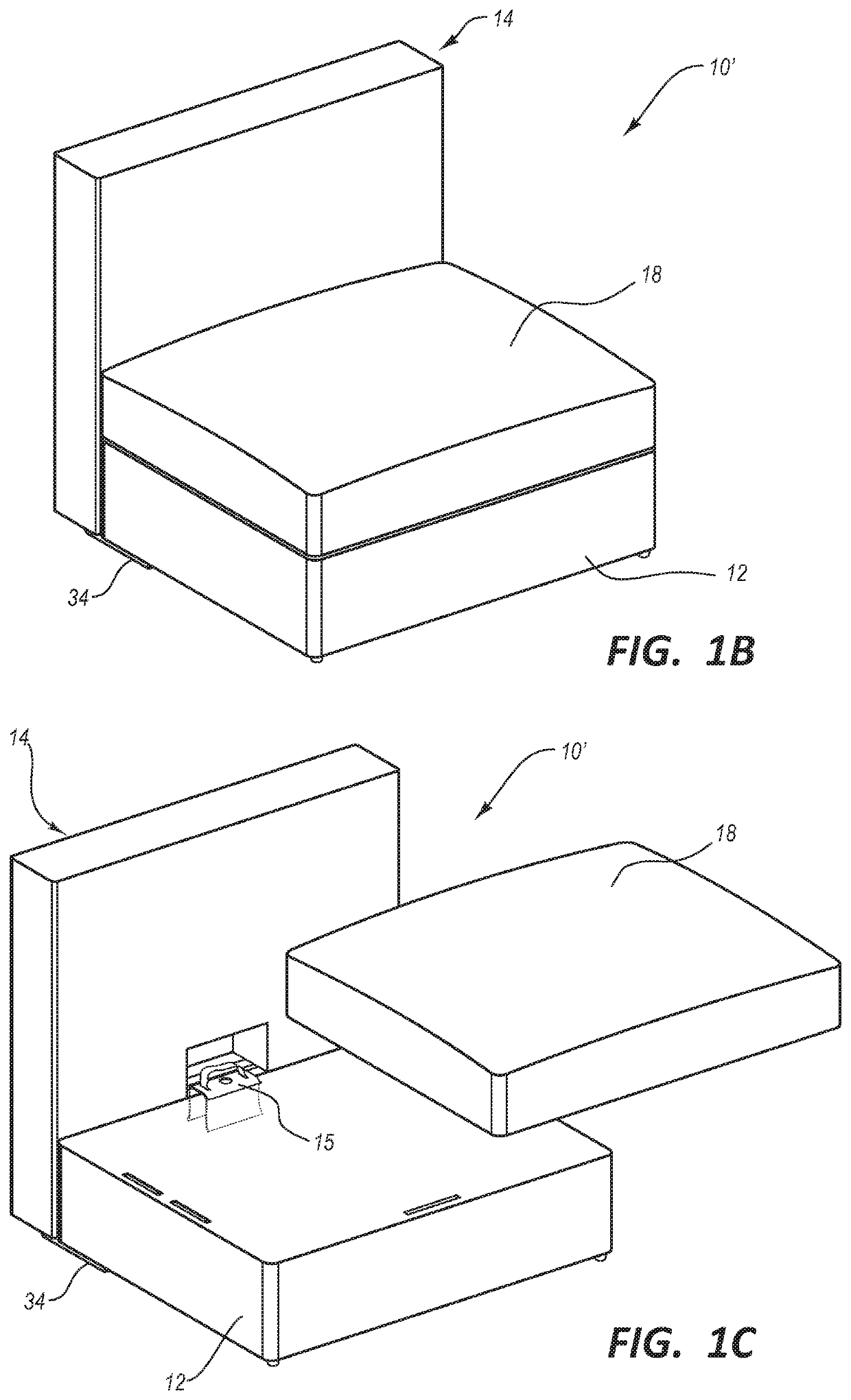

[0029]FIG. 1A is a perspective view of a modular furniture assembly in the form of a chair 10, one or more components of which may be man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap