Case for powdered cosmetic product including an improved opening/closing device

a cosmetic product and opening/closing technology, applied in the field of cosmetic products with improved opening/closing devices, can solve the problems of uncontrolled discharge of powdered cosmetic products, unsanitary, and difficult to use by users, and achieve the effect of simple and comfortable movement and convenient use for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

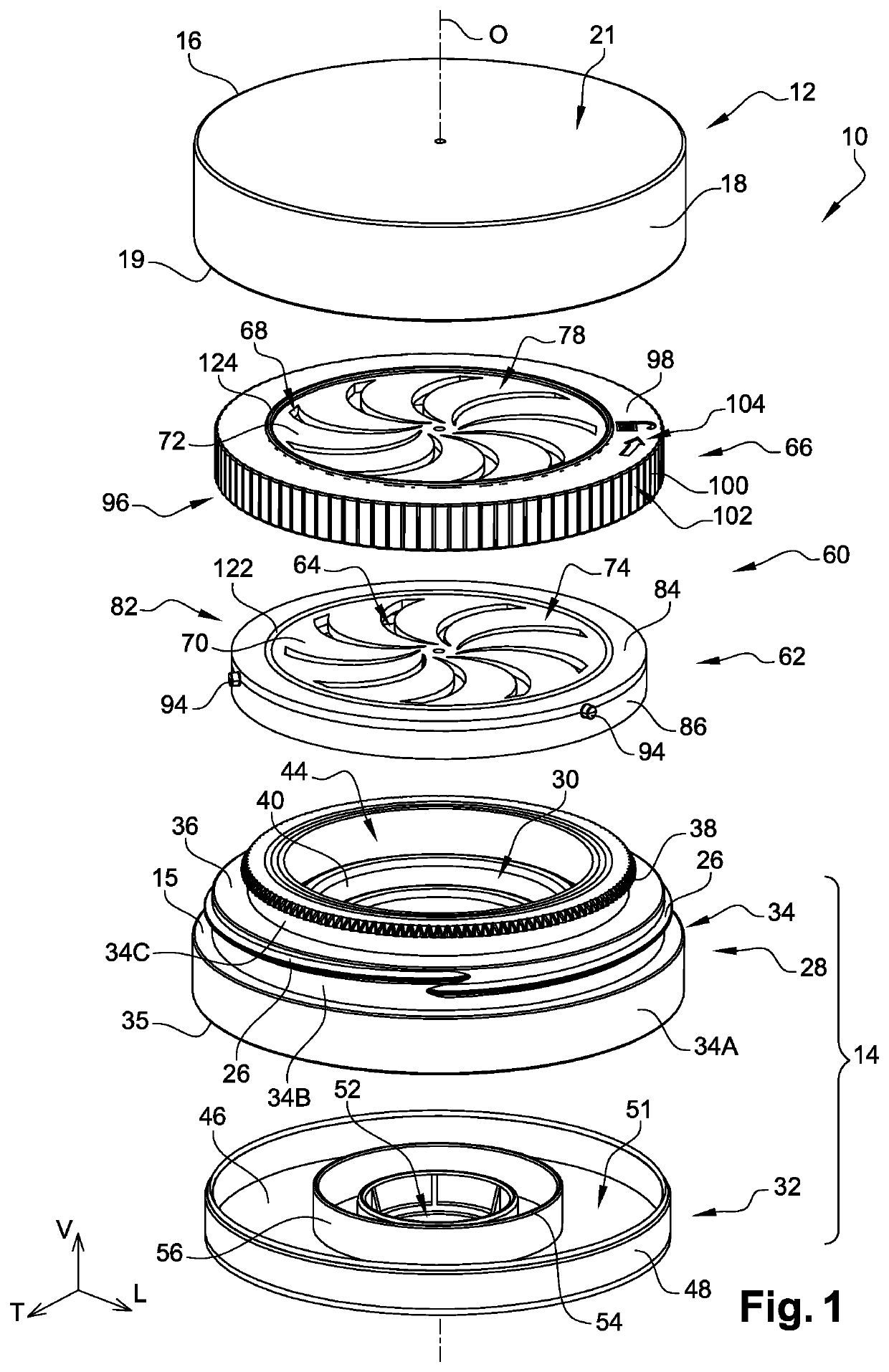

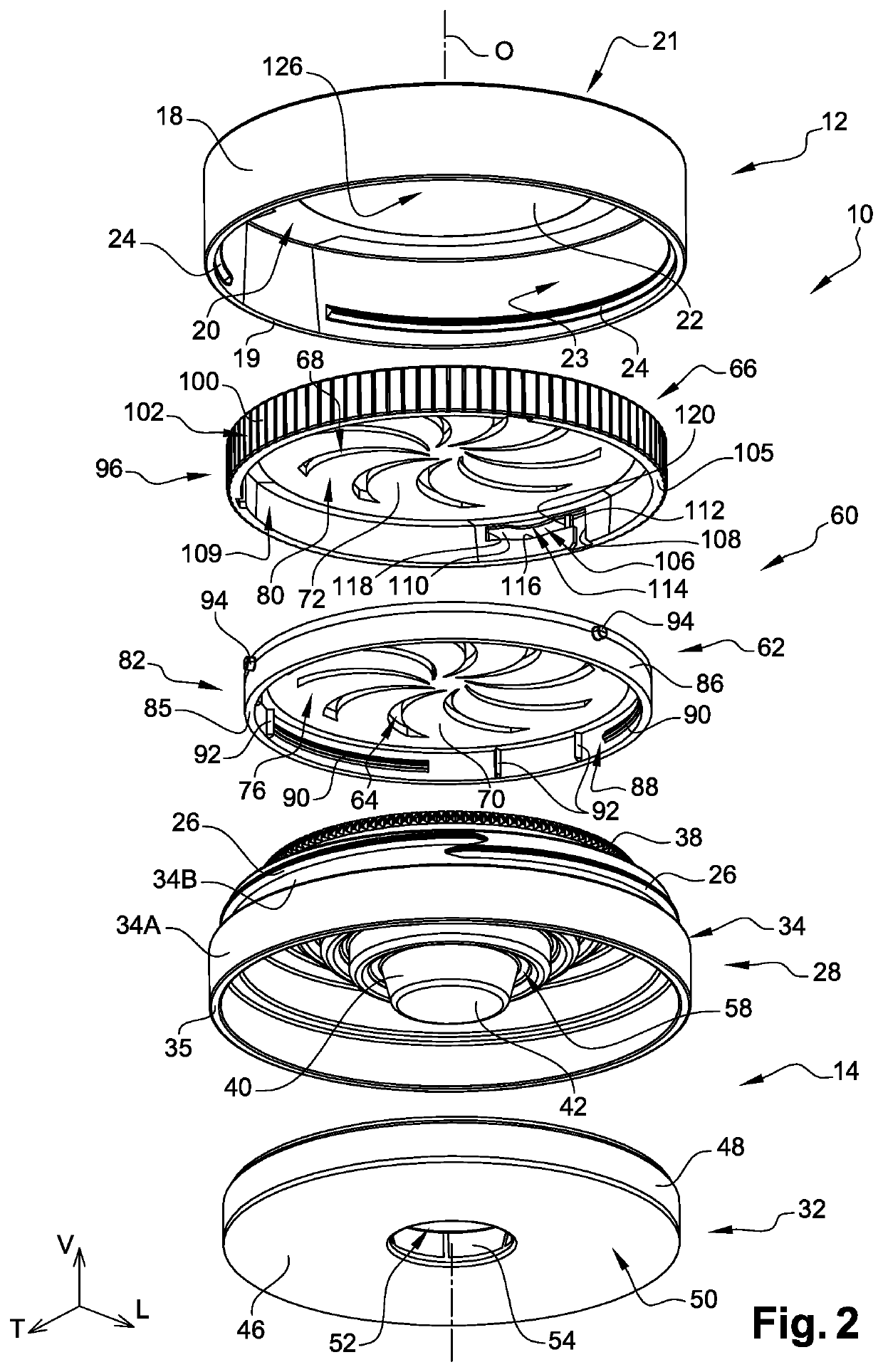

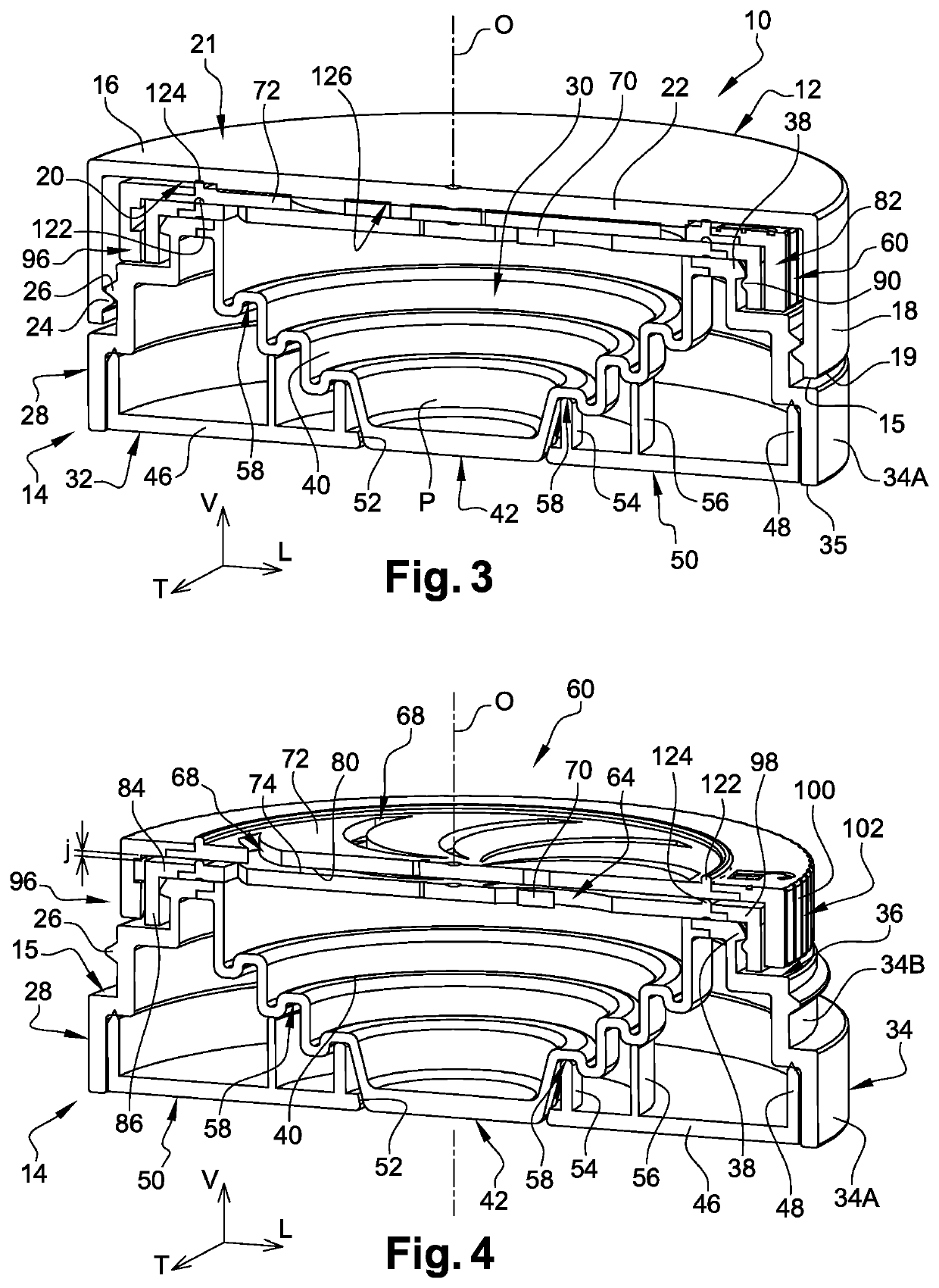

[0183]In this first embodiment, the cavity 30 is formed by a part 40 which is secured to the body 28 of the base 14. In a variant, the part 40 can be designed as a full refill, which could be mounted reversibly to the body of the base.

[0184]Preferably, the part 40 is flexible and mainly has the shape of bellows, here a truncated and tiered shape. This bellows includes an alternating succession of folds 58 and concentric, flat, annular surfaces. There are three folds 58 in this example. However, there could be more or less folds. The folds 58 have a staircase profile, and not a saw-tooth profile like an accordion. This makes it possible to have concentric, flat, annular surfaces between the folds 58. These concentric, flat, annular surfaces make it possible to receive the product P.

[0185]The part 40 includes a bottom 42 axially delimiting the lower end thereof and the outer diameter of the part 40 increases successively from the bottom 42 to the upper end thereof, which delimits an o...

second embodiment

[0371]In this second embodiment, the base 14 is made of two parts, respectively the body 28 and the bottom 32.

[0372]By comparison, the body 28 of the base 14 does not include any bellows-shaped part 40.

[0373]The bottom 32 is consequently modified and differs from that of the first embodiment in that it does not include, in particular, an opening 52 or partitions 54, 56.

[0374]Advantageously, the bottom 32 is structurally simplified.

[0375]According to one of the characteristics of this second embodiment, the cavity 30 is integrally formed with the body 28 of the base 14.

[0376]By comparison, the cavity 30 of the case 10 according to this second embodiment has a volume which is less than that obtained with the bellows-shaped flexible part 40.

[0377]Thus, a case 10 according to one or the other of the embodiments will be selected according to the desired volume of powdered cosmetic product P.

[0378]By comparison with the first embodiment shown in FIGS. 1 to 9, a third embodiment of a case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com