Ecdysozoans trap

a trap and ecdysozoan technology, applied in the field of ecdysozoans and traps for catching ecdysozoans, can solve the problems of time-consuming, expensive, and difficult work with existing technologies, and achieve the effects of reducing the risk of ecdysozoans, and reducing the number of traps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Test

Experiment 1

Material and Methods

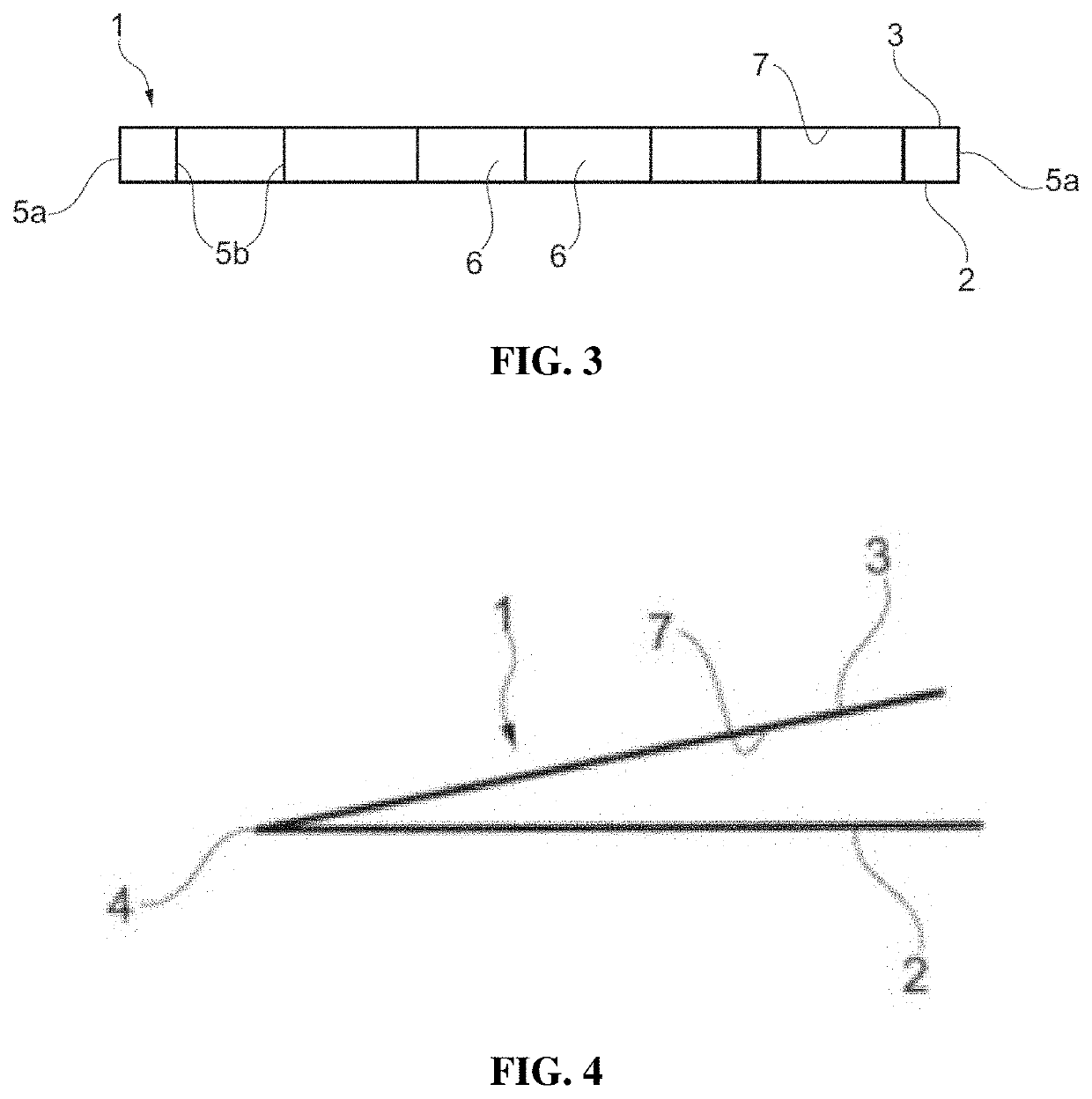

[0193]Two traps (one with smooth floor and one with rough floor) were placed in a plastic tray facing each other. The smooth floor was made of smooth plastic (polypropylene 55 μm, referred as smooth floor) from Pockets Din (Brony by doculine, 099007). The rough floor was made of sandpaper (240 grains / cm2, referred as rough floor). The roof of the traps was made of black paper coated with double-sided adhesive tape (AXTON®) on its interior surface. Twenty-five bedbug individuals (5 males, 5 females and 15 nymphs of all stags) were placed in the center of the tray. The number of individuals glued to the double-sided adhesive tape was noted after 15 hours.

Results

[0194]Results are presented in Table 1.

TABLE 1Comparison between smooth and rough floorSmoothRough floorfloorp-valueR1317R2321R3124Total762R: replicate

[0195]These results show that bed bugs significantly entered into traps with rough floor, compared to traps with smooth floor. On average, ove...

experiment 2

Material and Methods

[0196]A plexiglass plate comprising areas sanded with different densities of sandpaper (4000, 3000, 2000, 1000, 400, 280, 120, 80 and 60 grains / cm2) was used. Sandpaper of 4000 grains / cm2 provides a very fine sanding, while sandpaper of 60 grains / cm2 leads to important scratch on the plexiglass plate. The ease of bedbugs to travel on each sanded area was observed. Then the capacity of bedbugs to climb on the support when it is tilted was investigated.

Results

[0197]Bedbugs have great difficulty moving through plexiglass areas sanded with sandpapers of 4000 to 1000 grains / cm2 (they slide). However, the more the density decreases, the more bedbugs have facility to move, which is reflected by an increase of their travel speed (data not shown). When the plexiglass plate is tilted, bedbugs are not able to hold onto and slide along the plexiglass areas of 4000 and 3000 grains / cm2. From 2000 grains / cm2, bedbugs are able to hold on to the support even vertically.

[0198]Ther...

experiment 3

Material and Methods

[0199]The same experiment as in Experiment 2 hereinabove was performed on two other materials with increasing roughness: sand paper and plastic rough-textured plastic.

Results

[0200]Bedbugs were found to slide on smooth materials and materials very slightly rough. The mobility of individuals increased up from a density of about 1000 grains / cm2 to 200 grains / cm2. Then, individuals have increasing difficulties in mobility on materials with a greater roughness, from 180 to 60 grains / cm2.

[0201]Therefore, the mobility of individuals to enter into the trap depends on roughness of the material. The results show that the most appropriate density increased up to 200 grains / cm2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com