Resiliently bonded heat exchanger

a heat exchanger and resilient technology, applied in the field of heat exchangers, can solve the problems of affecting the life of heat exchangers of many types, affecting the efficiency of heat exchangers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

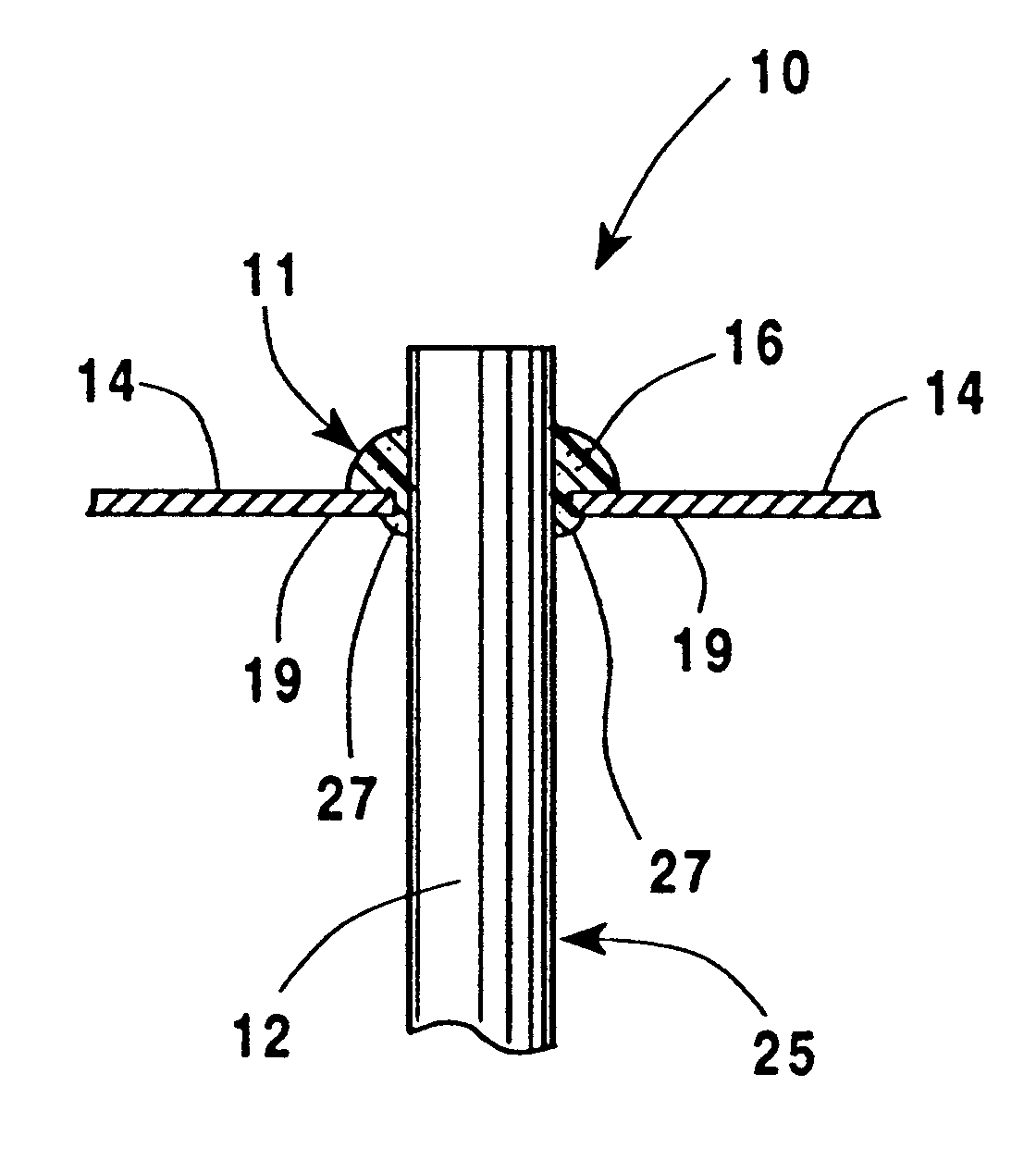

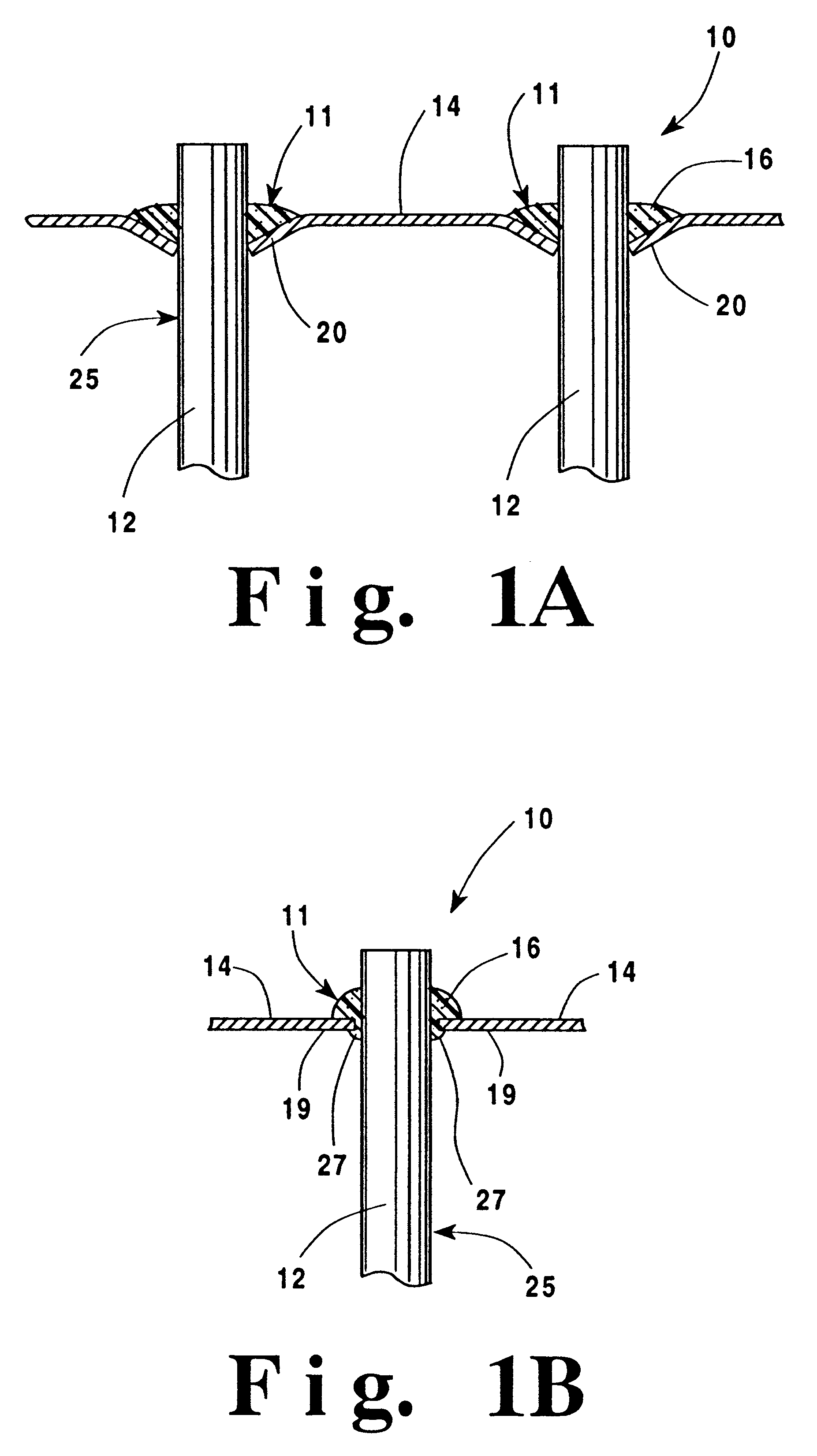

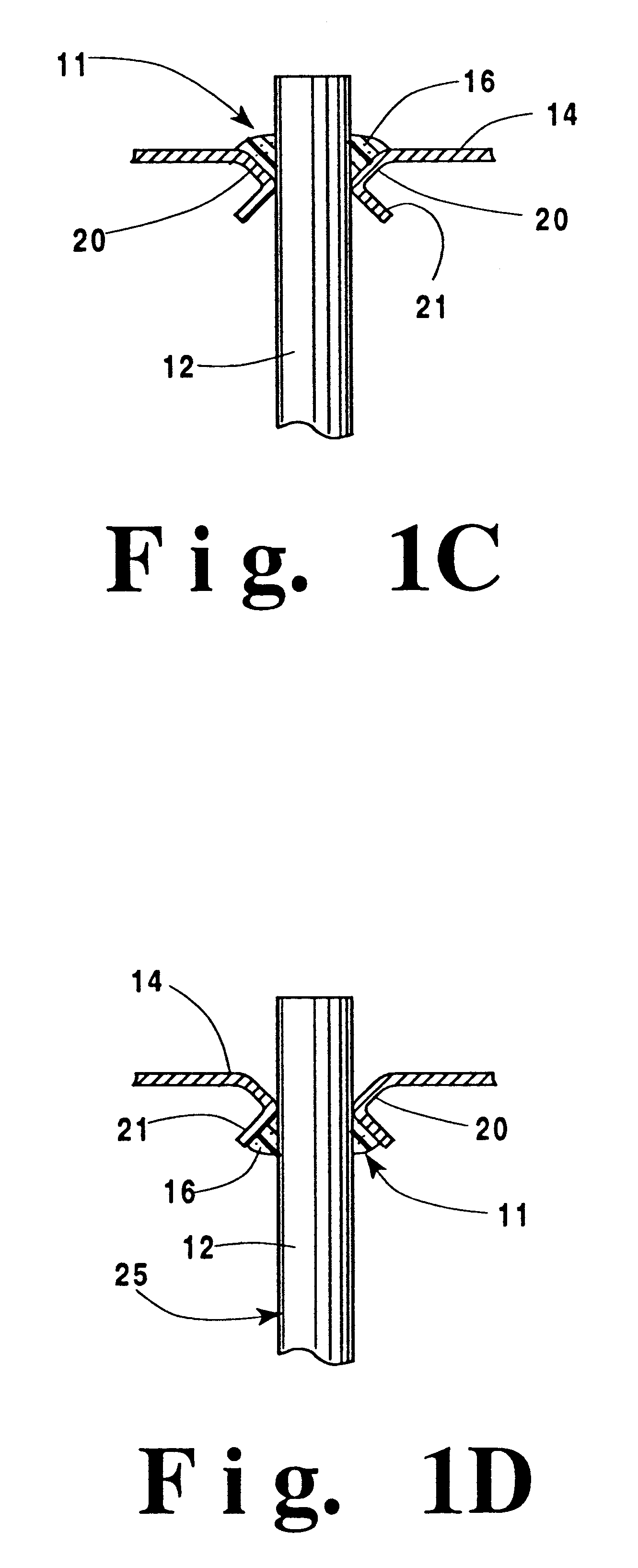

In describing the preferred embodiments of the present invention, reference will be made herein to FIGS. 1-10 of the drawings in which like numerals refer to like features of the invention. Features of the invention are not necessarily shown to scale in the drawings.

Generally, the present invention provides a method of producing flexible liquid tight seals using formed in place and cured in place techniques. The seal can be provided in a tank-to-header joint or a tube-to-header joint. Curing the seal after the assembly of the parts has specific advantages including providing a bonded liquid tight sealing joint instead of a compression fit sealing joint, and enhanced ease of assembly. Moreover, other advantages using the present invention include the expansion and contraction of the flexible joints when other components of the heat exchanger are also expanding and contracting. Also, the flexible nature of the joints provides a long life heat exchanger. Further, the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com