Articulated headrestraint system

a headrest and articulation technology, applied in the field of articulation headrest systems, can solve the problems of dependencies of the movement of the headres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

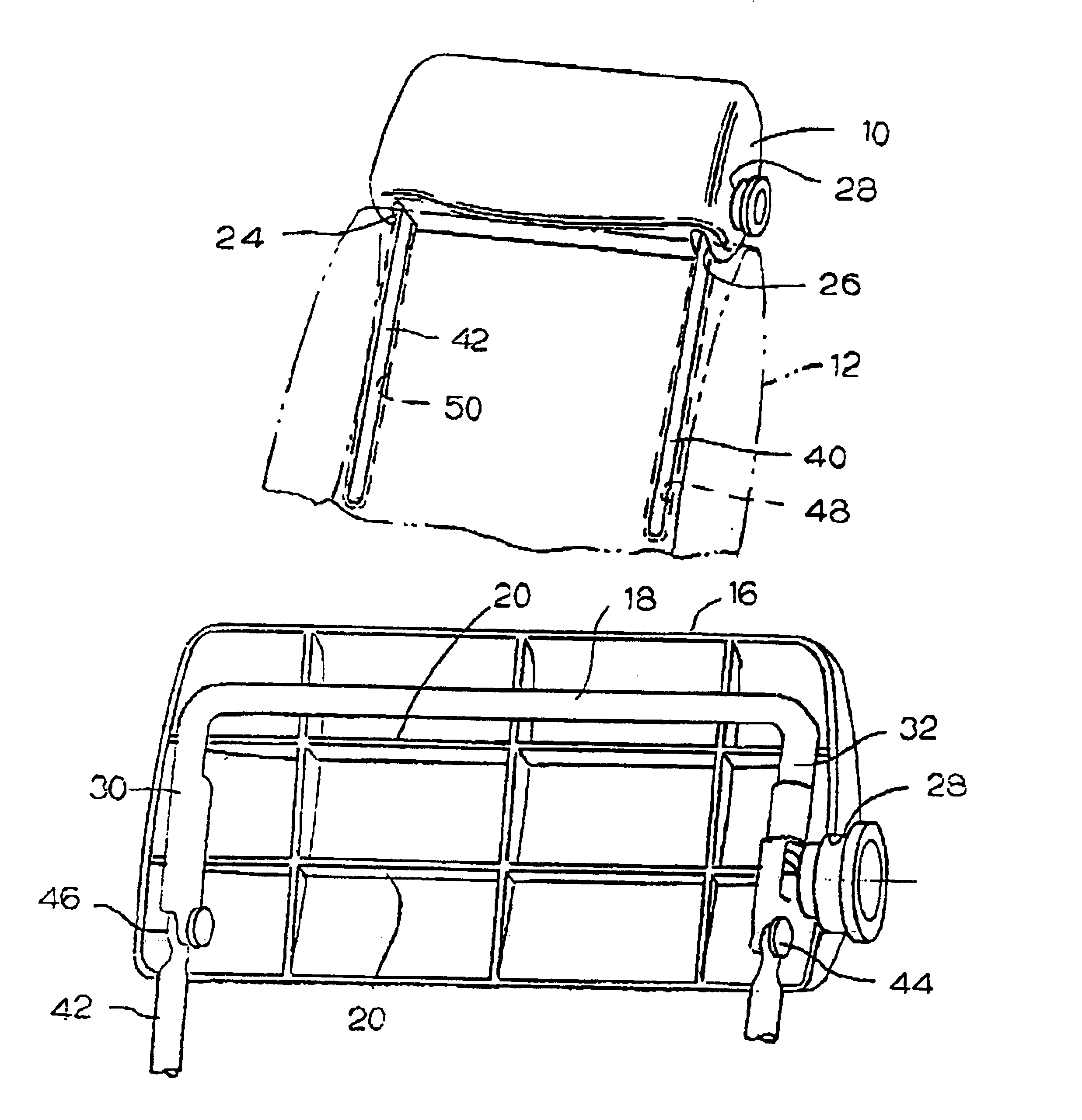

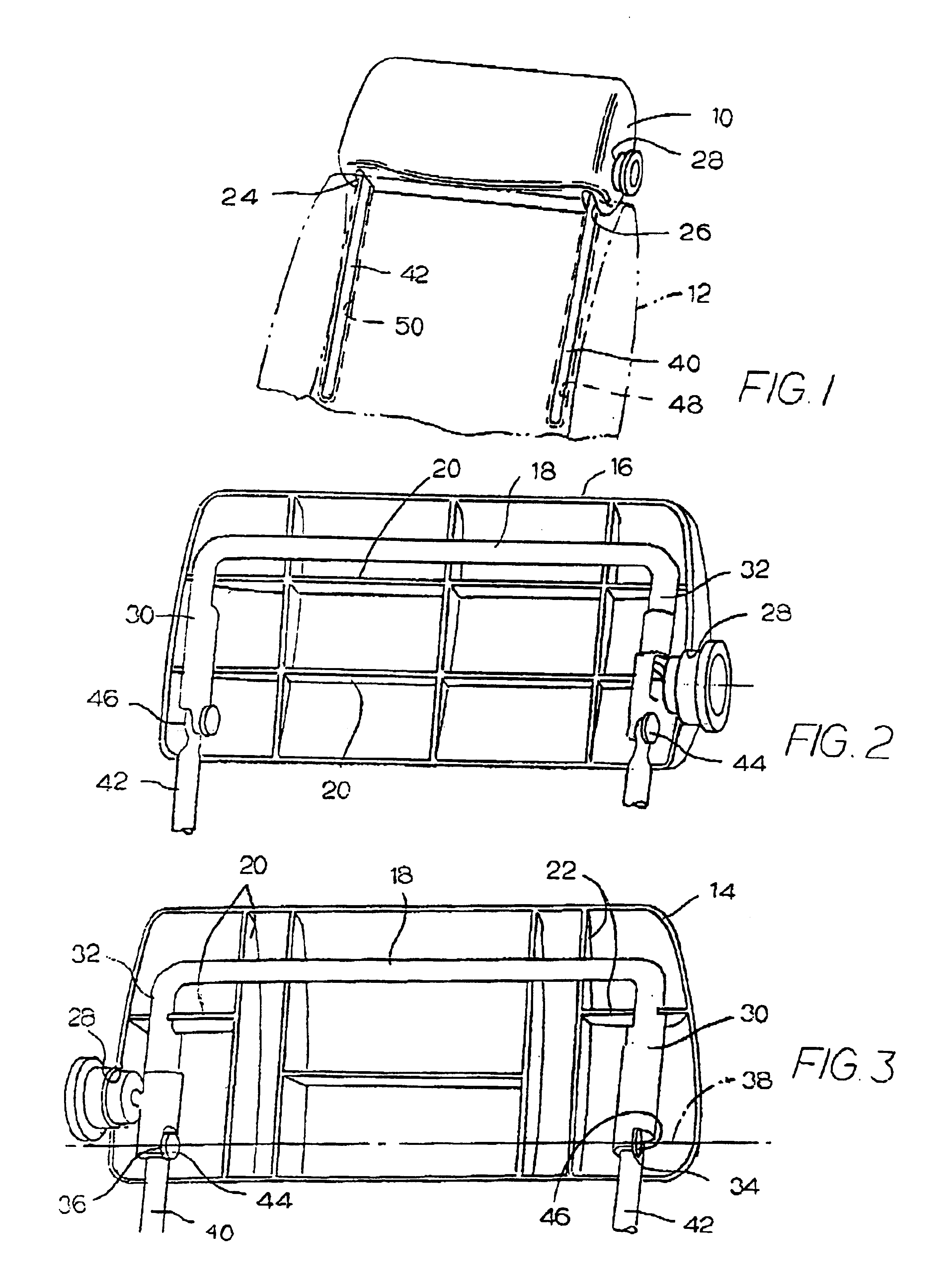

[0024]Referring to the drawings, FIG. 1 illustrates an adjustable headrest 10 mounted on a vehicle seat back 12, illustrated in phantom. Referring to FIGS. 2 and 3, headrest 10 includes a back cover 14 fastened to a front cover 16. The two covers have edges formed together to form a hollow headrest housing. A U-shaped tubular upper support member 18 is captured between the front and rear covers in ridge means 20 and 22, respectively. When the two covers are joined together, they combine to form a pair of lower slots 24 and 26. The two covers also combine to form a side button opening 28. Support member 18 is fixed to and moves with the two covers.

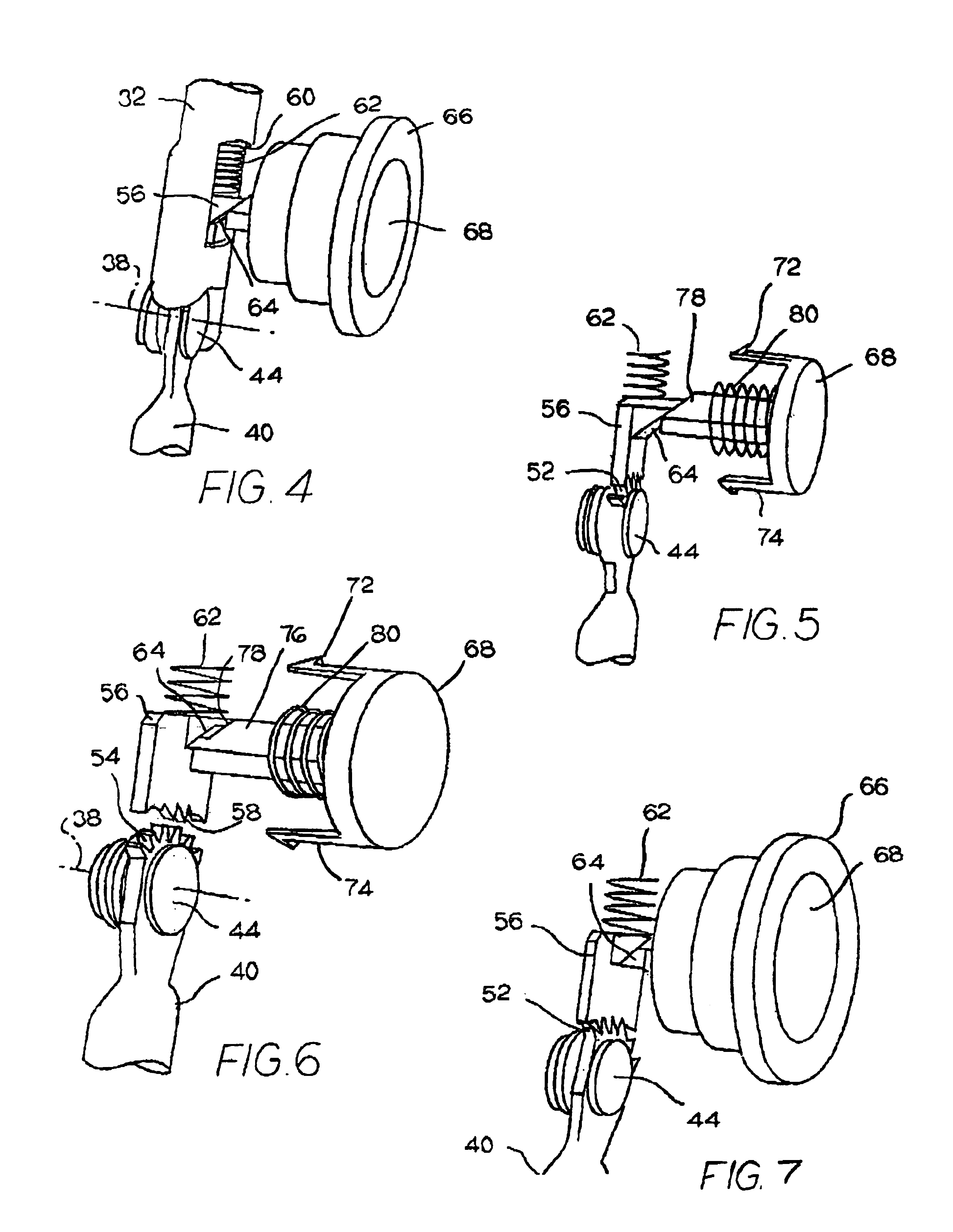

[0025]Support member 18 has a pair of parallel brackets 30 and 32. The lower ends of the two brackets have rivet-receiving openings 34 and 36, aligned along a pivotal axis 38.

[0026]A pair of upright parallel legs 40 and 42 have upper flattened ends connected by rivet means 44 and 46 to the lower ends of brackets 32 and 30, respectively. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com