Pitcher-shaped active area for field effect transistor and method of forming same

a field effect transistor and active area technology, applied in the field of semiconductor devices, can solve problems such as low electric field, and achieve the effects of reducing contact resistance, increasing transistor on-current, and reducing transistor serial resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

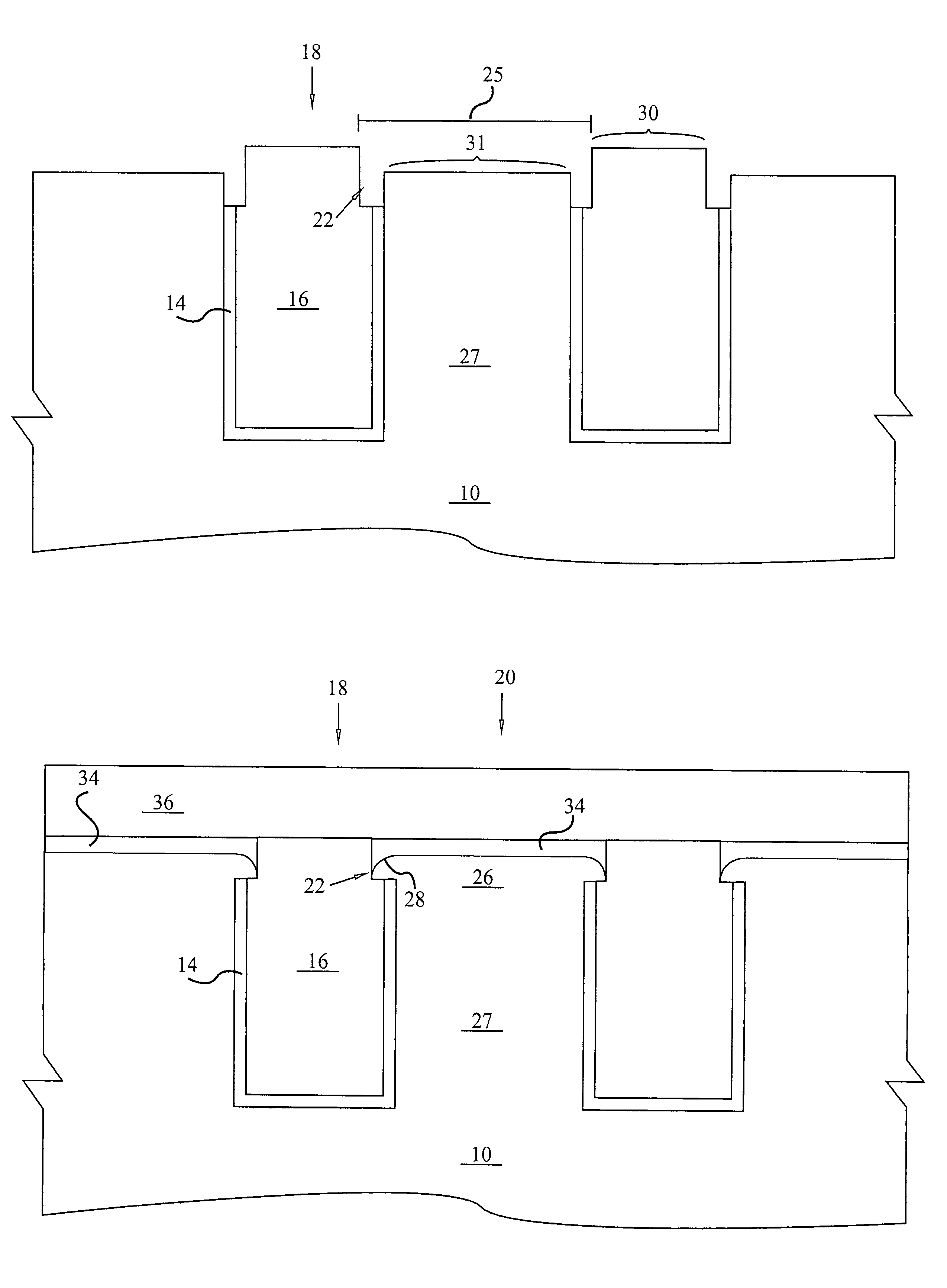

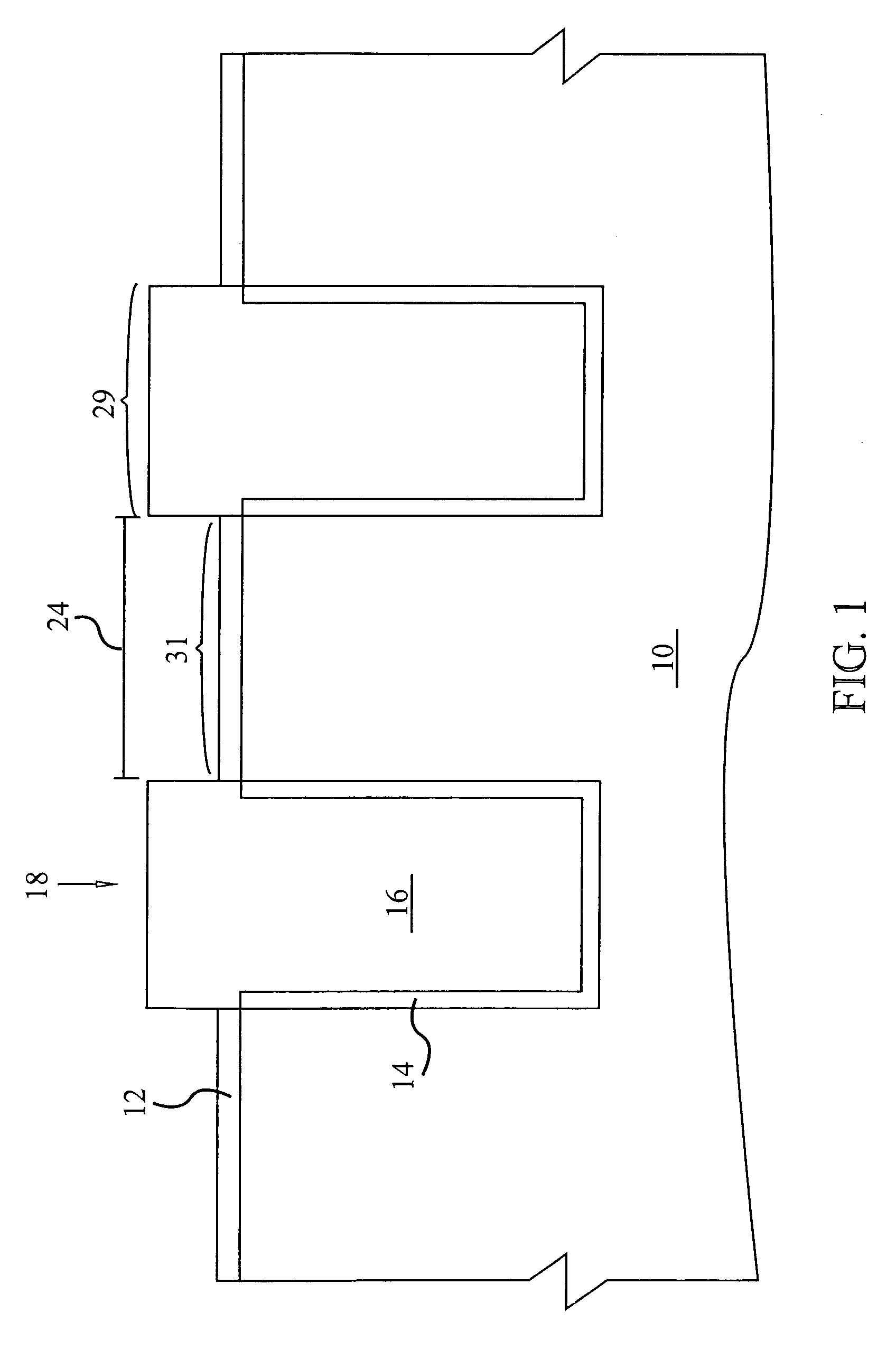

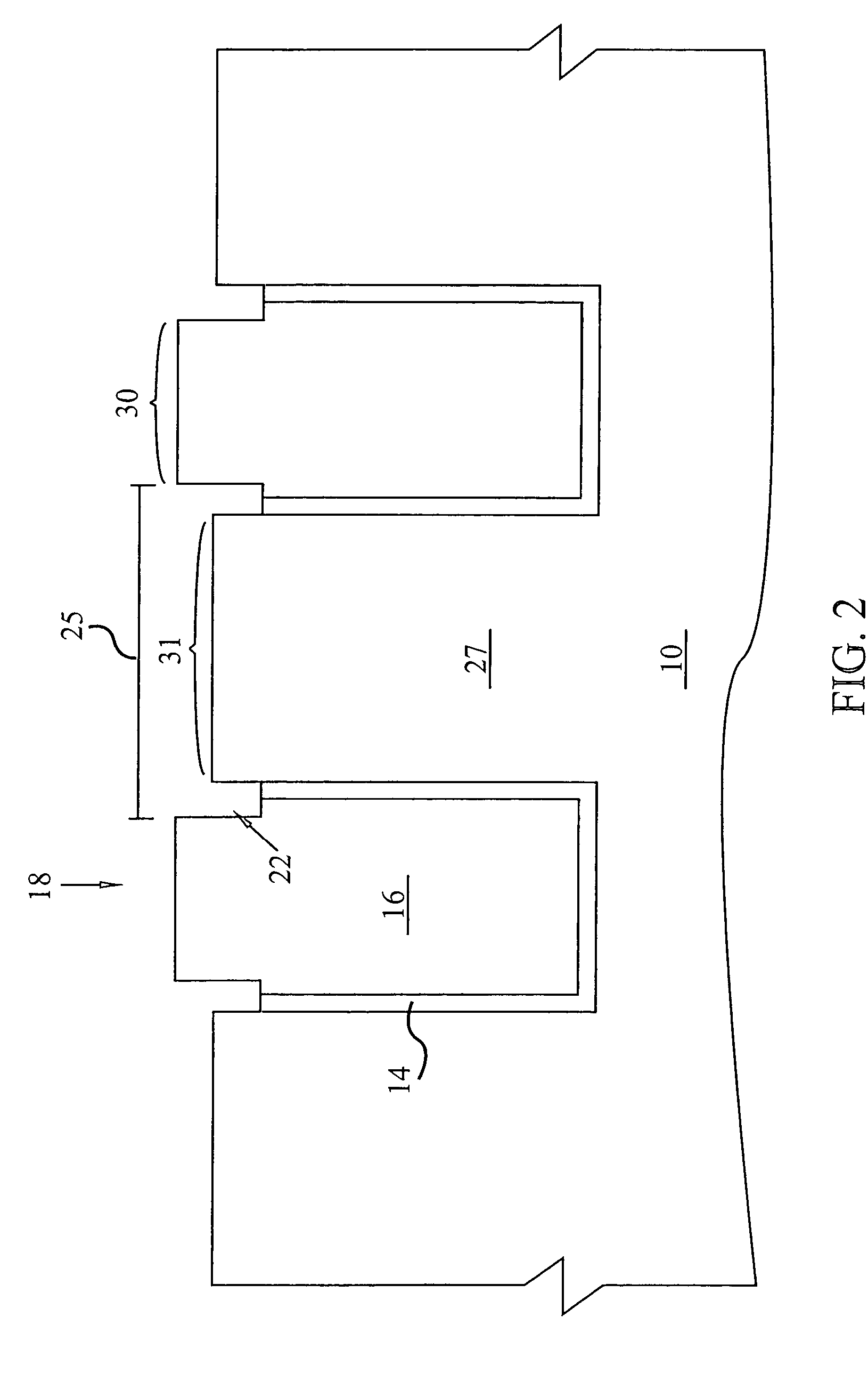

[0017]Although the present invention may be readily adapted to a variety of methods of fabricating a FET, with reference to FIGS. 1–4, the following is an example of a method of fabrication. FIGS. 1–4 are cross-sectional views depicting various stages during the fabrication process of pitcher-shaped active area 20 of a FET, as depicted in FIGS. 3 and 4. Generally, the improved fabrication method of present invention may form pitcher-shaped active area 20 by implementing a step to form divots 22 in top portions of the side walls of STI structures 18. Following the formation of divots 22, a step may be implemented to migrate substrate material into STI divots 22, thereby forming widened top portion 26 of pitcher-shaped active area structure 20. It will be understood by one of ordinary skill in the art that the invention is not limited to the specific structures illustrated in the drawings or to the specific steps detailed herein. It will also be understood that the invention is not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com