Automatic jacking system for an automotive vehicle

a technology for automobiles and jacking systems, applied in vehicle maintenance, transportation and packaging, vehicle fittings for lifting, etc., can solve the problems of many motorists with little mechanical skills, many motorists with damaged or flat tires, and many motorists who cannot maintain flat tires. , to achieve the effect of safe, efficient and relatively quick manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

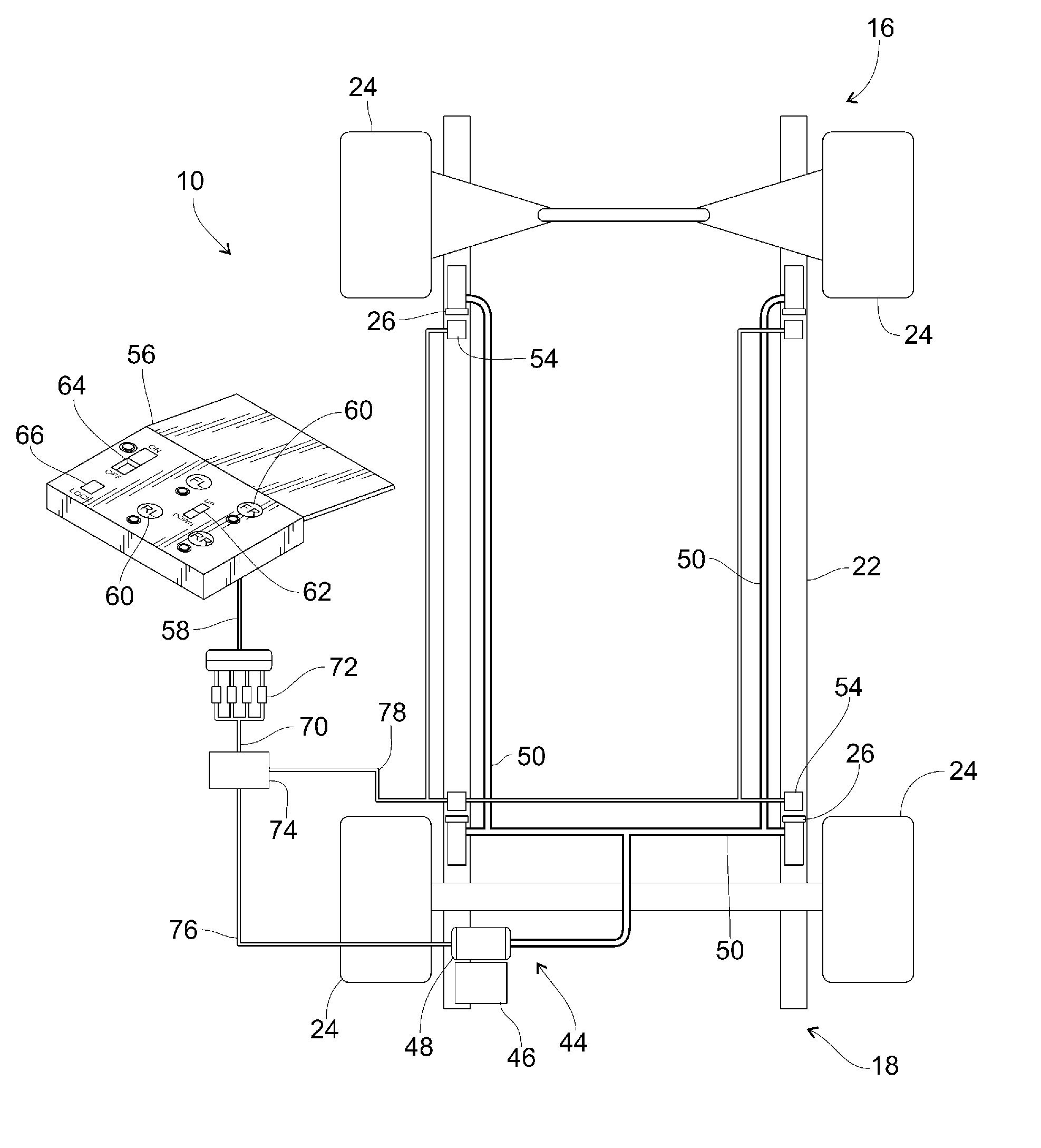

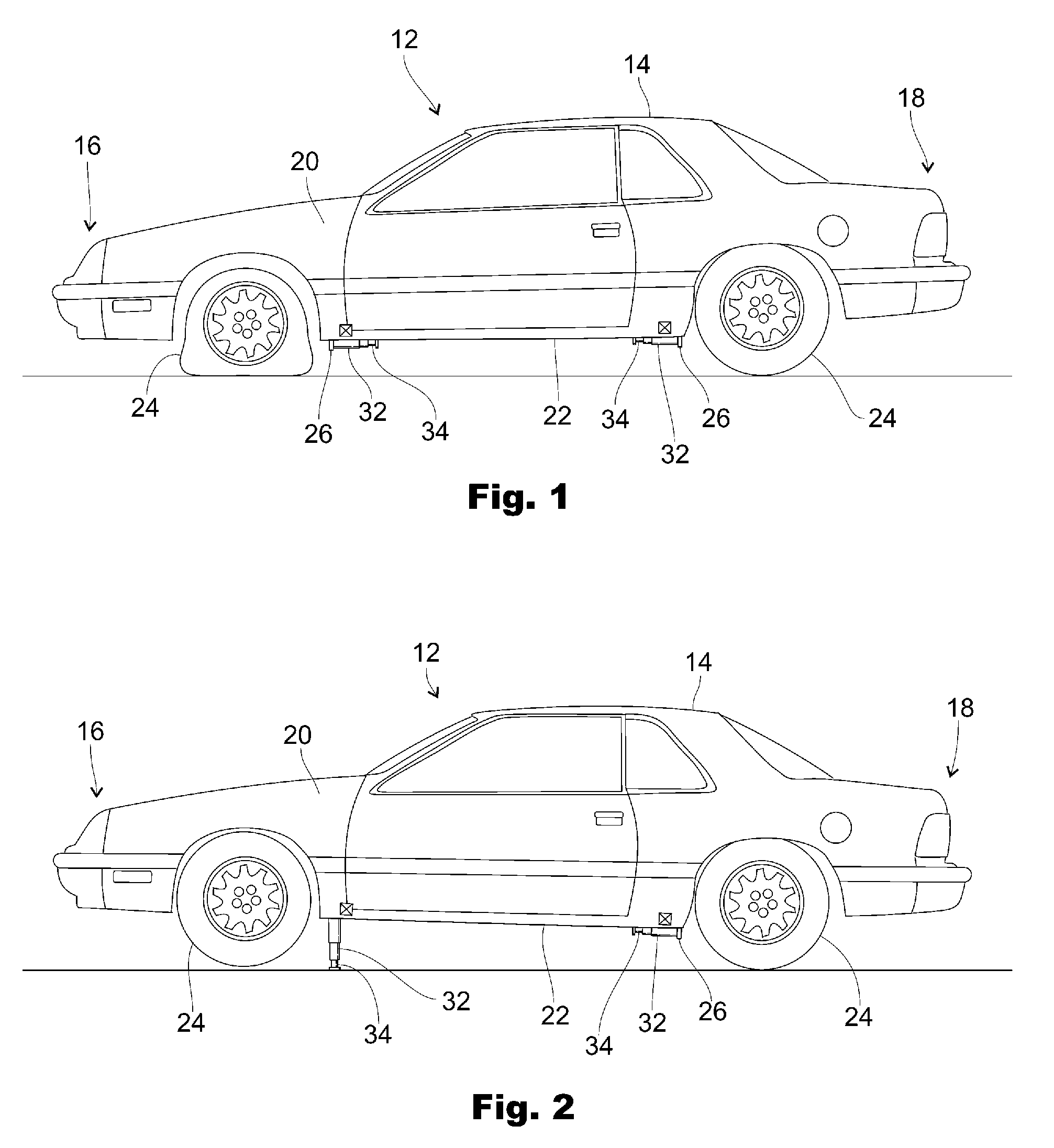

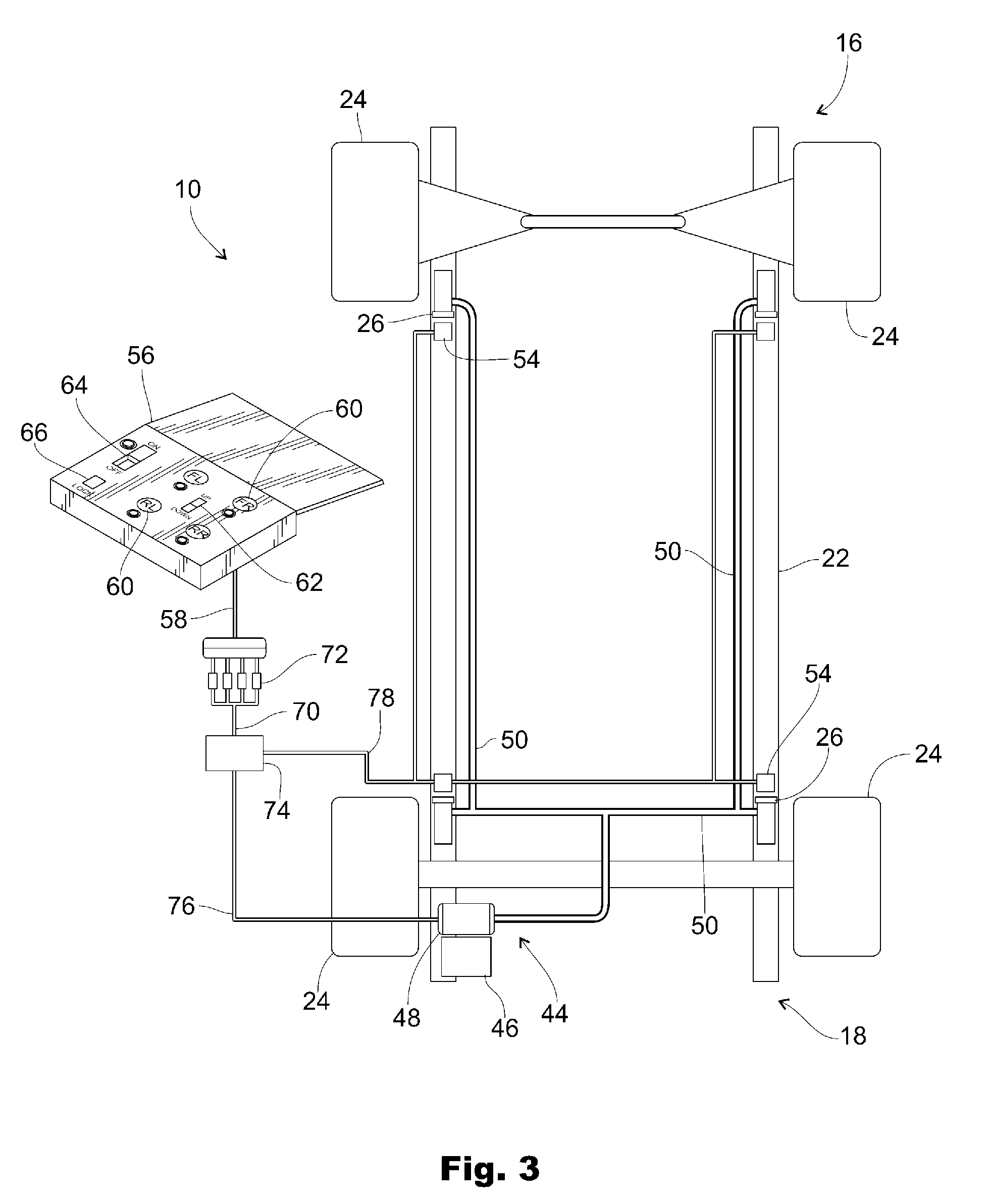

[0029]Illustrated in FIGS. 1–6 is an automatic jacking system 10 for an automotive vehicle 12 such as the automobile 14 of FIGS. 1 and 2. The automobile 14 includes a front end 16 and an opposite rear end 18, an automobile body 20 having an underside frame or chassis 22 and four wheels 24—specifically, left and right front tires and left and right rear tires. The automatic jacking system 10 can be incorporated with the electrical system of the automobile 14 for providing the electrical power for the system 10, and the automatic jacking system 10 allows the individual / vehicle operator to safely and quickly raise the automobile 14 to repair or change the tire, and then safely lower the automobile 14 after tire repair and changing has been completed. It is generally intended that the automatic jacking system 10 of the present invention be sold as an after market product. FIG. 1 shows the automatic jacking system 10 folded into the storage or non-disposed state and FIG. 2 shows the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com