Memory disk shipping container with improved contaminant control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

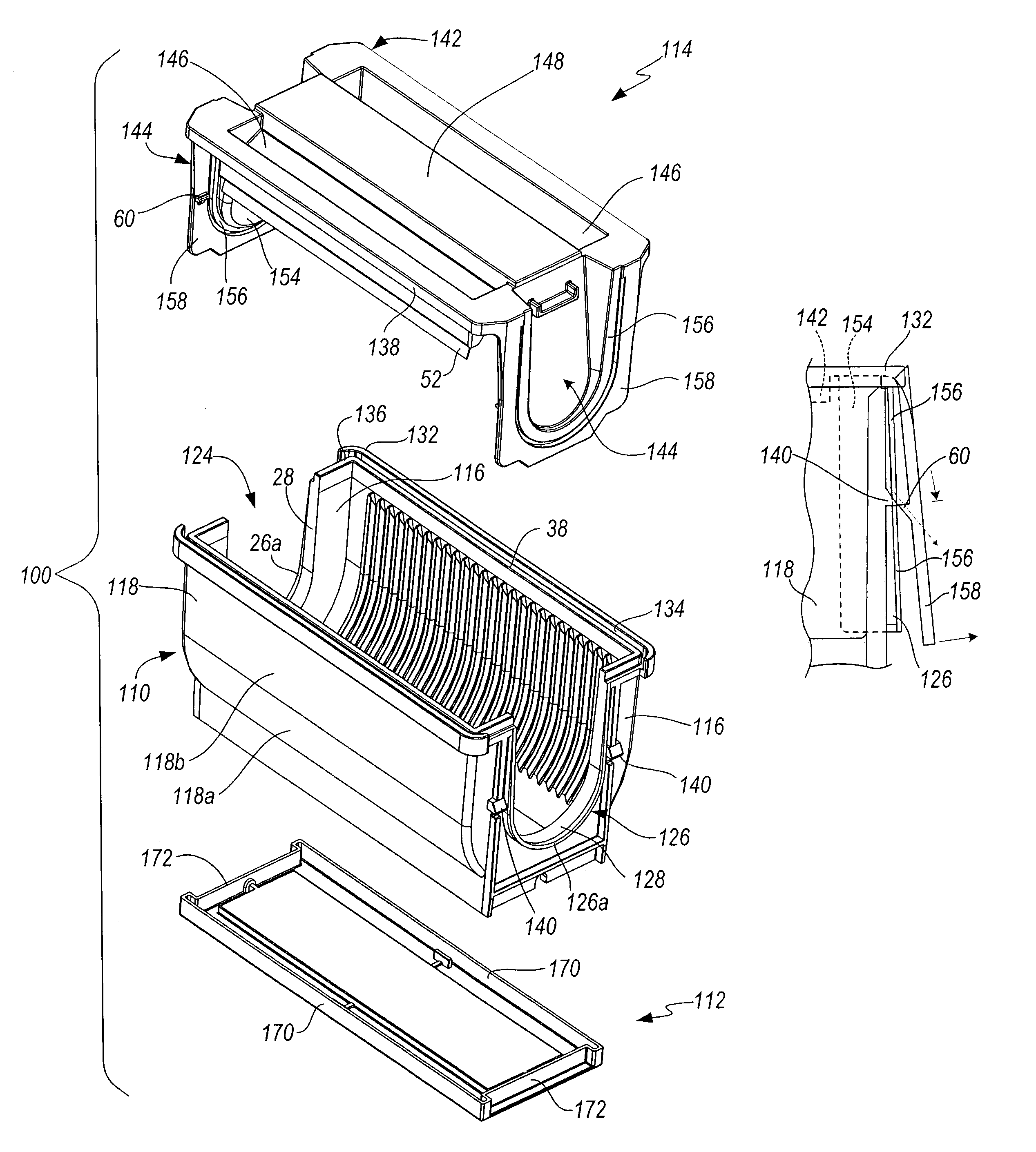

[0050]Referring first to FIG. 9, the invention is shown in the context of a shipping and storage container for memory disks generally designated with the numeral 100. When used alone herein, “disk” should be considered as any type of memory disk, including both magnetic and optical memory disks. In general terms and with reference to the drawings, the disk shipper is comprised of three pieces: a base or cassette 110 having an open top, open bottom and open ends; a bottom cover 112 for enclosing the open bottom of the cassette and, a top cover 114 for enclosing the open top and open ends of the cassette. The cassette, as illustrated in more detail in FIGS. 10–17, has two end walls 116 and two parallel side walls 118 extending between the end walls. Slots 120 are formed in the side walls of the cassette by inwardly extending teeth or ribs 122. The slots are configured to hold magnetic disks in parallel axial alignment by engaging the outer edge portions of the disks. The side walls 11...

second embodiment

[0056]the present invention is shown in FIGS. 24–31. In this embodiment, the base or cassette 202 and the top cover 204 remain generally the same. However, the latching mechanism is different. Turning to the cassette 202, and more particularly, the end walls 206, a pair of cutout portions 208 and 210 are formed on the underneath surface of the lower portion of the saddle 212 to create a ridge or lip 214 (see FIG. 25). The lip 214 cooperates with a locking member associated with the top cover to secure the cover to the cassette.

[0057]As shown in FIGS. 24, 26, 27 and 29, the top cover 204 includes a locking member 216 pivotally attached to the top cover 204 by a hinge 218. The hinge 218 permits the locking member 216 to pivot relative to the top cover while, simultaneously, the U-shaped structural offset 220 is sealably nested within the saddle 212 when the top cover 204 is properly seated on the cassette 202. This allows the locking member 216 to pivot upwardly and downwardly about t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com