Apparatus and method for fatigue testing

a fatigue testing and apparatus technology, applied in the direction of tensile/compressive force, instruments, mechanical means, etc., can solve the problems of difficult to achieve blade aerofoil shape and blade root shape, and the behaviour of specimens that do not accurately reflect the behaviour of real blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

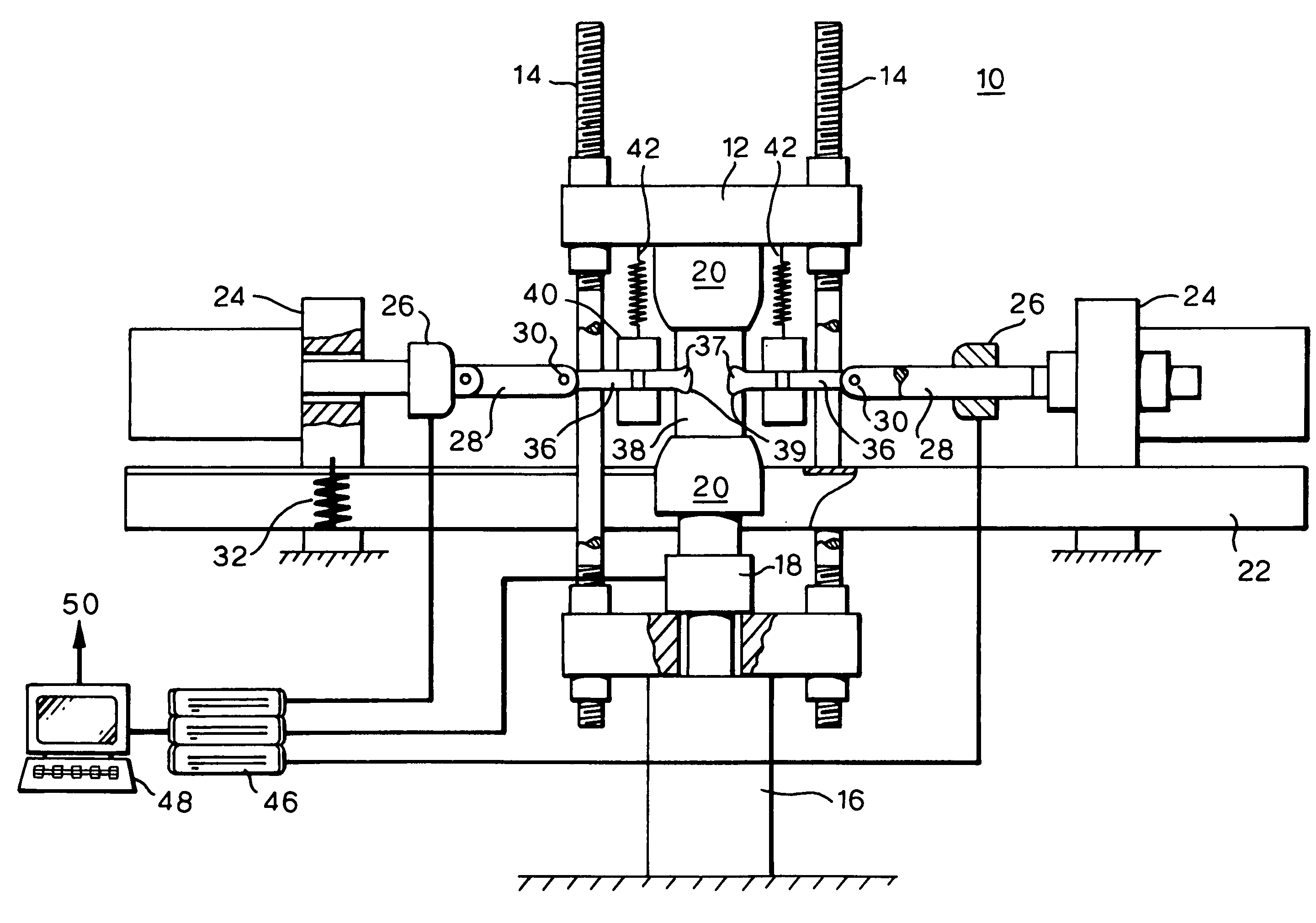

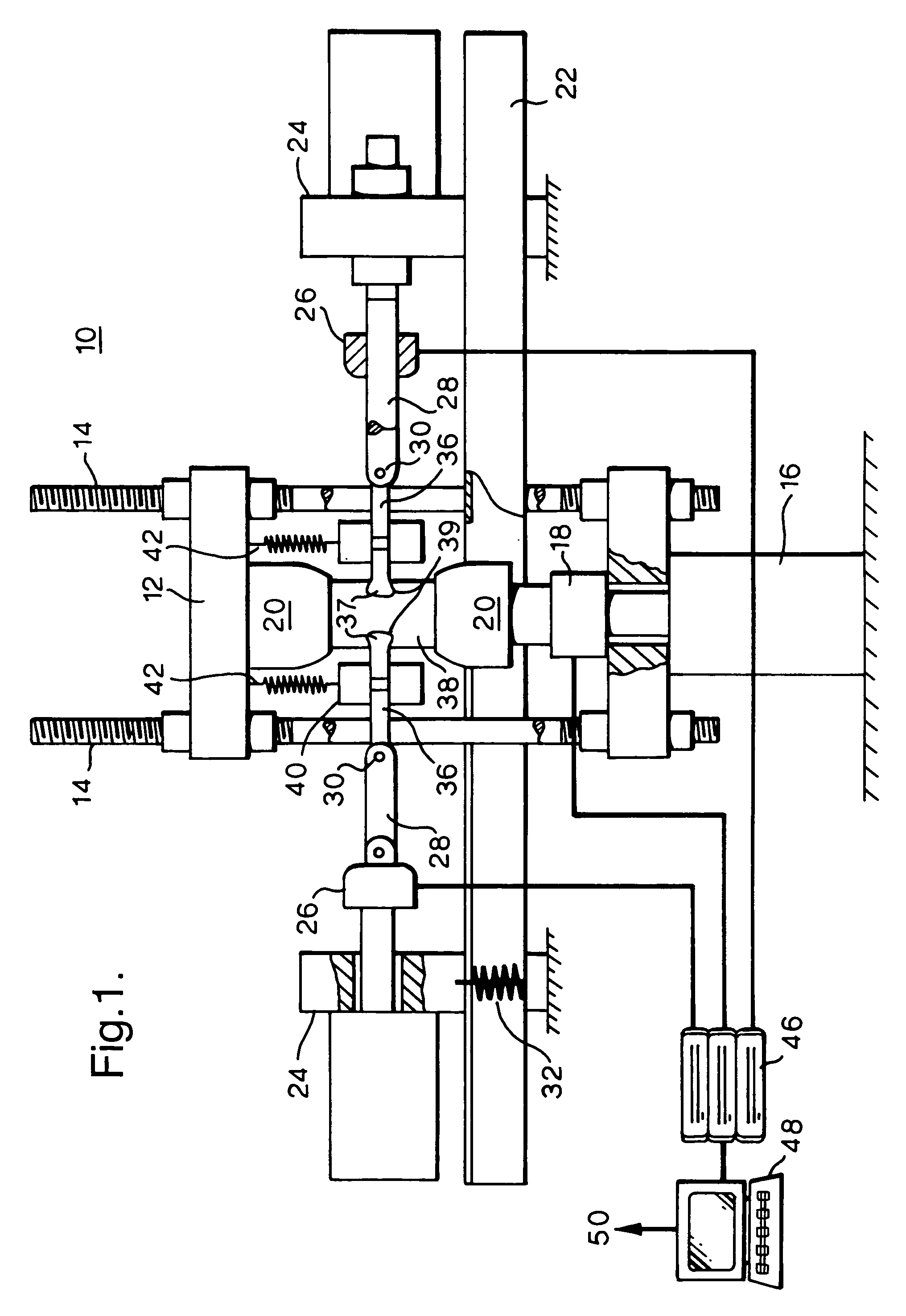

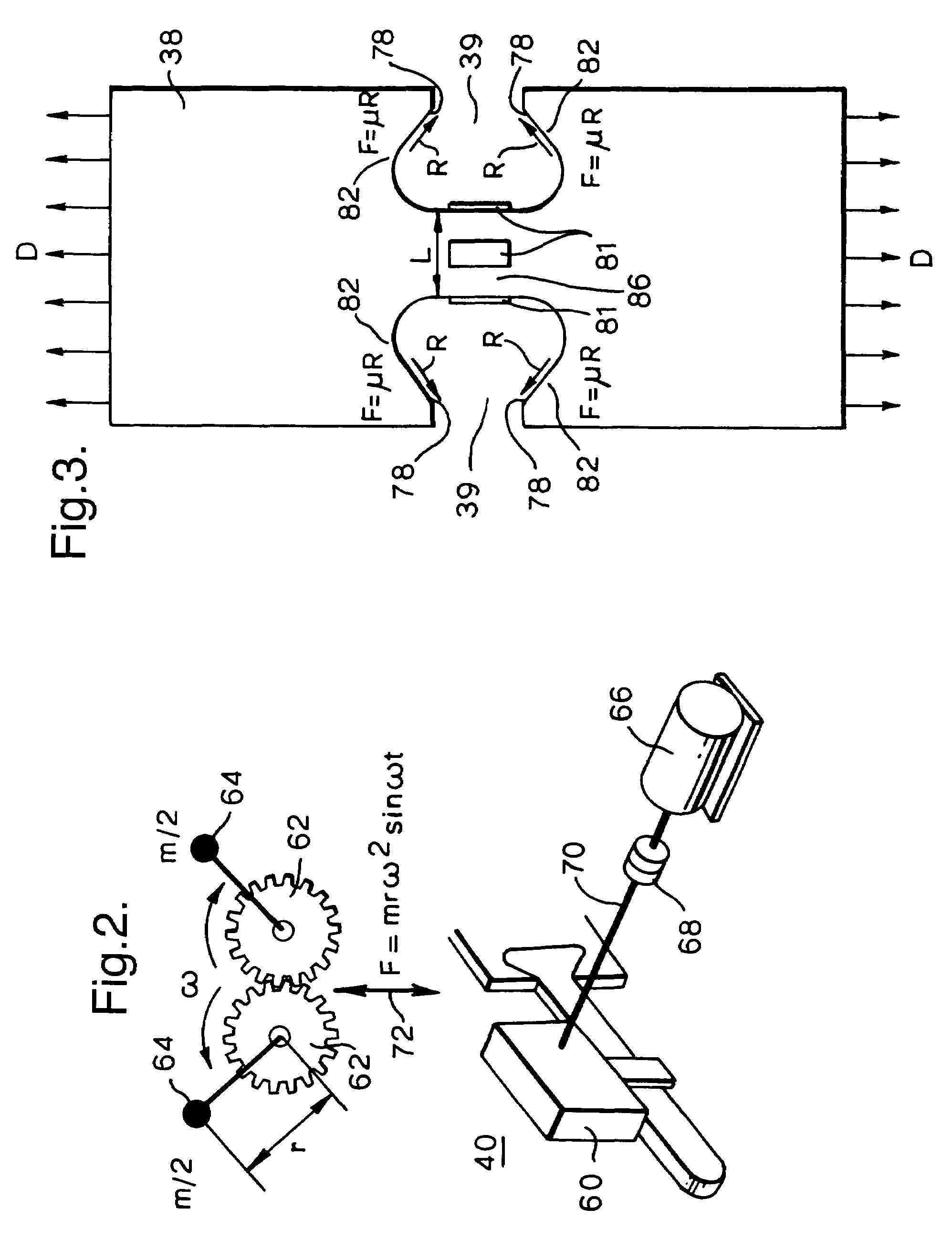

[0029]Referring first to FIG. 1, a test machine shown generally at 10 has a load frame 12. Pillars 14 support a first hydraulic actuator 16 and a first load cell 18, and a pair of grips 20. Further structure 22 supports second hydraulic actuators 24, second load cells 26 and a pair of loading bars 28. Each loading bar 28 has a hole 30 near its end, into which a pin (not shown) can be fitted.

[0030]A fixture 38 is securely held between the grips 20 of the testing machine 10. The fixture 38 has two recesses 39 matching the profile of the disc slots whose behaviour is to be reproduced.

[0031]Two test specimens 36 have, at one end, a mounting feature 37 matching the profile of the blade whose behaviour is to be reproduced and, at the other end, a suitable hole permitting pin attachment of the test specimens 36 to the loading bars 28, in the conventional manner.

[0032]In operation, the first actuator 16 applies a load to the fixture 38. The applied load is measured by the first load cell 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com