Card connector

a card connector and connector technology, applied in the direction of coupling contact members, coupling device connections, instruments, etc., can solve the problems of inability to provide the card with an appropriate friction force, plastic deformation of the contact piece, and the need for contact pressure cannot be given to the contact terminal, so as to prevent the card from falling out of the connector. , the effect of holding the card steady and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

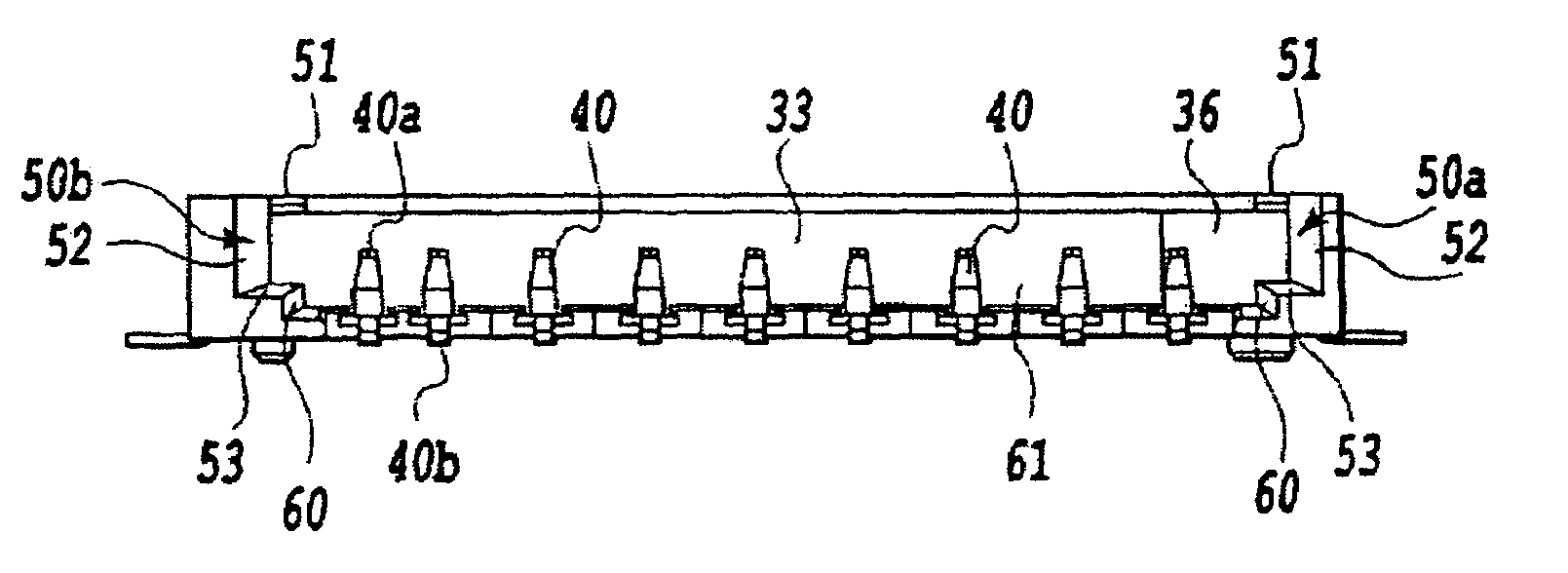

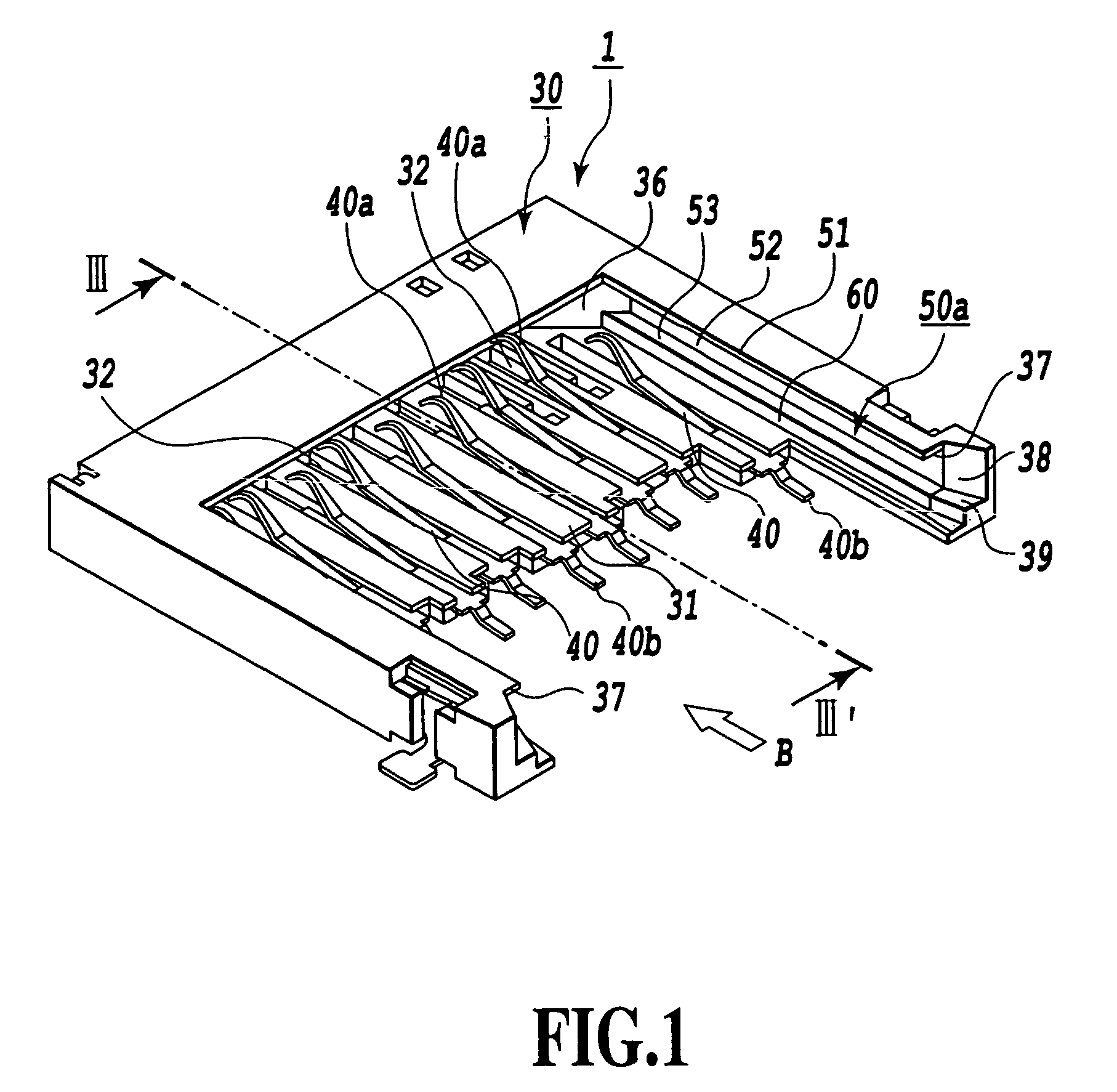

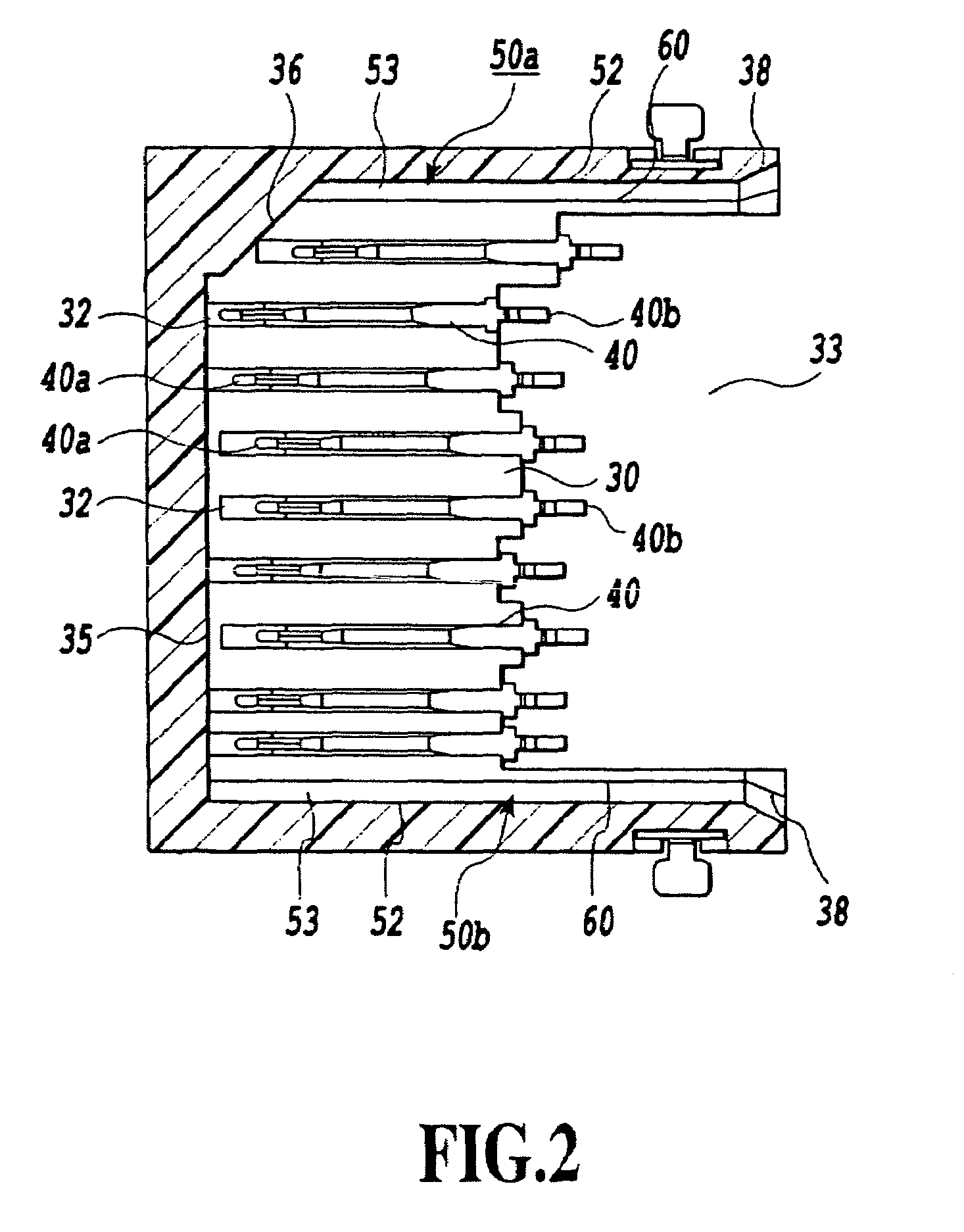

[0053]FIG. 1 is a perspective view showing a card connector according to the first embodiment of this invention. FIG. 2 is a horizontal cross section of the card connector. FIG. 3 is a cross section taken along the line III-III of FIG. 1. FIG. 4 is a front view of the card connector as seen from the direction of arrow B in FIG. 1.

[0054]The card connector 1 is mounted on an electronic device, such as cellular phone, PDA, portable audio device and camera.

[0055]The connector 1 shown in FIG. 1 to FIG. 4 can accommodate both a thin card 10 such as an MMC card shown in FIG. 16 and FIG. 17 and a double-height thick card 20 with step portions such as an SD card shown in FIG. 18 and FIG. 19.

[0056]In FIG. 1 to FIG. 4, the card connector 1 has a connector housing 30 roughly U-shaped when viewed from above and which is made from an insulating material such as resin and formed in one piece having side leg portions.

[0057]A base plate 31 of the connector housing 30 is formed with a plurality of pr...

second embodiment

[0073]Next, the second embodiment of the present invention will be described by referring to FIG. 8 to FIG. 14.

[0074]FIG. 8 is a plan view showing a card connector according to the second embodiment of this invention. FIG. 9 is a front view of the card connector as seen from a direction of arrow B in FIG. 8. FIG. 10 is a partly cutaway plan view of the card connector.

[0075]The connector 1 shown in FIG. 8 to FIG. 10 can accommodate both a thin card 10 such as an MMC shown in FIG. 16 and FIG. 17 and a double-height thick card 20 with step portions such as an SD card shown in FIG. 18 and FIG. 19. Components with the same functions as those of the first embodiment are assigned like reference numbers to facilitate the understanding of the second embodiment.

[0076]In FIG. 8 to FIG. 10, a base plate 31 of the connector housing 30 is formed with a plurality of press-fit grooves 32 in which a plurality of contact terminals 40 made from contact leaf springs are fitted under pressure. The conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com