Method and an apparatus for shape measurement, and a frequency comb light generator

a frequency comb light and shape measurement technology, applied in the field of shape measurement methods and apparatuses, can solve the problems of time-consuming observation by the system, inability to observe the deep portion inside the measured object, and inability to meet the needs of measurement, etc., and achieve the effect of simple configuration and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

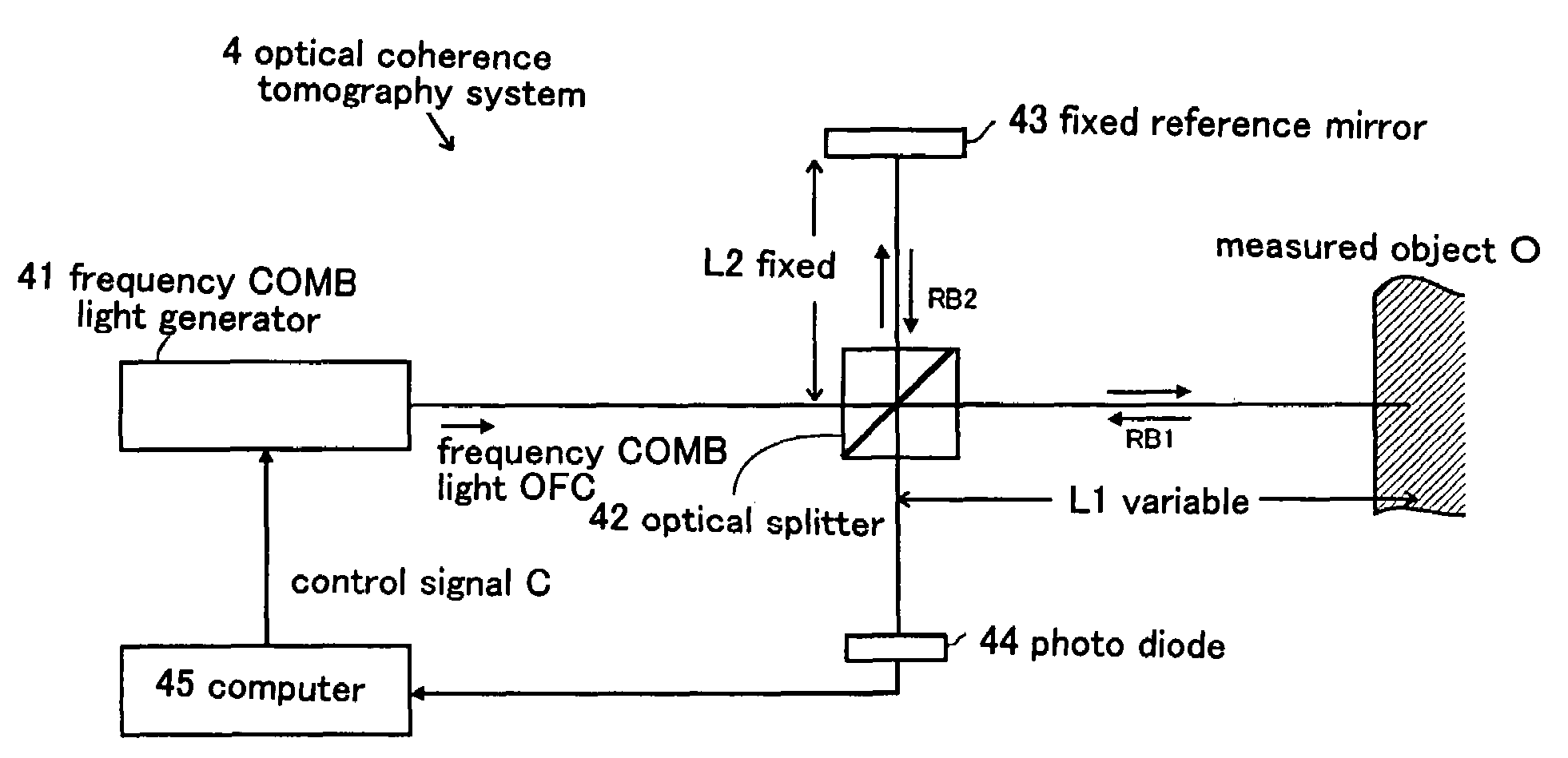

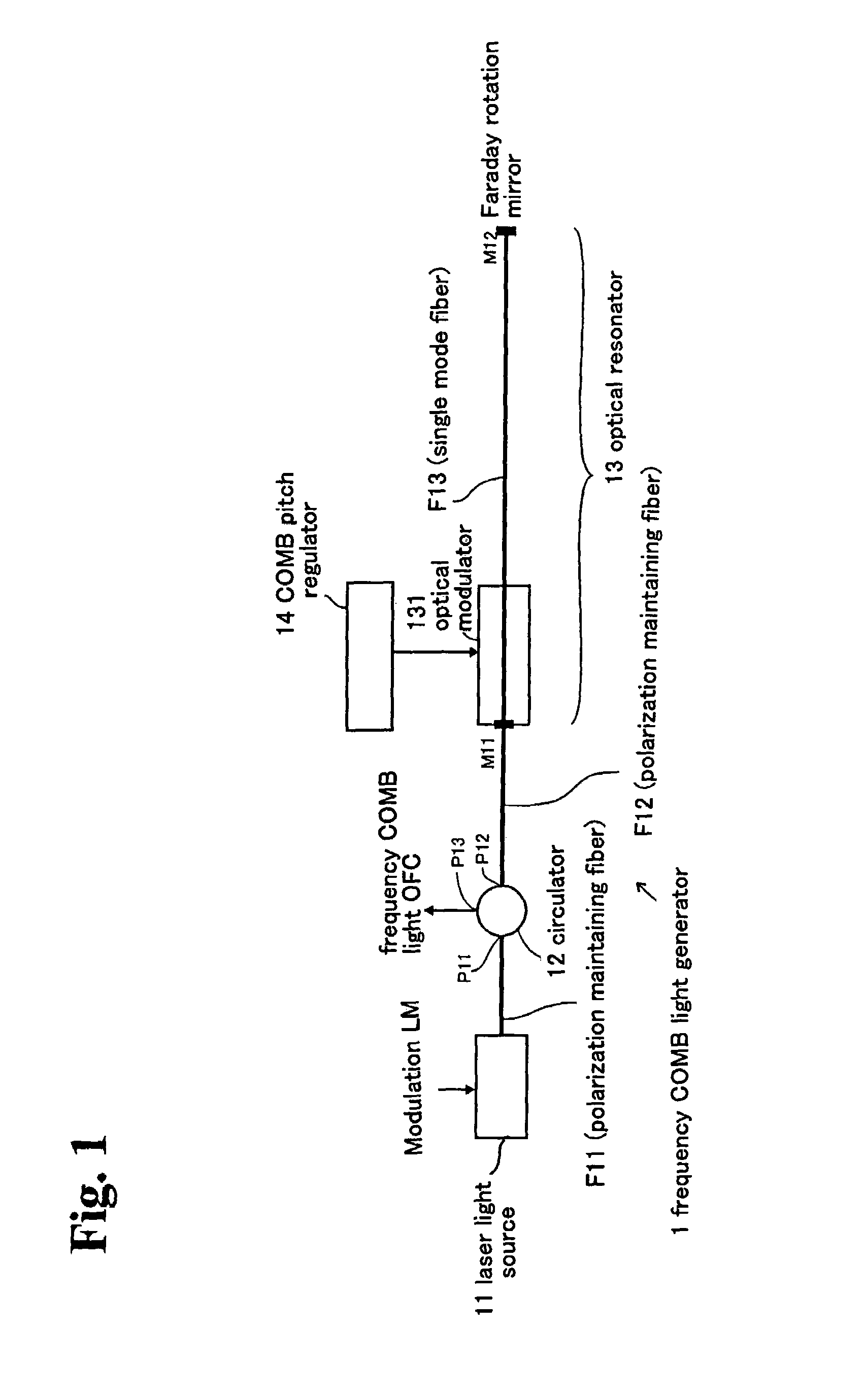

[0031]FIG. 1 is shows a frequency COMB light generator according to the present invention. In FIG. 1, the frequency COMB light generator 1 includes a laser light source 11, a circulator 12, an optical resonator 13 and a COMB pitch regulator 14.

[0032]In this embodiment, the laser light source 11 can output a laser light (center angular frequency ω0) in a wavelength band (e.g. 1.2˜1.6 μm) where the penetration efficiency inside a living body is high.

[0033]In FIG. 1, a modulation signal LM is input into the laser light source 11 and the output of the laser light source 11 can have a predetermined width (e.g. a width from hundreds MHz to GHz) for the center frequency ω0.

[0034]The circulator 12 is located between the laser light source 11 and the optical resonator 13, and the laser light source 11 is connected to a first port P11 through an optical fiber F11 (polarization maintaining fiber) and the optical resonator 13 is connected to a second port P12 through an optical fiber F12 (polar...

second embodiment

[0056]FIG. 5 shows the frequency COMB light generator according to the present invention. In FIG. 5, the frequency COMB light generator 2 includes a laser light source 21, an isolator 22, an optical resonator 23 and a COMB pitch regulator 24.

[0057]The laser light source 21 can output the laser light (center angular frequency ω0) in a wavelength band where the penetration efficiency in a living body is as high as the laser light source 21 in the first embodiment.

[0058]The isolator 22 is located between the laser light source 21 and the optical resonator 23, and the laser light source 21 is connected to a first port P21 through an optical fiber F21 (polarization maintaining fiber) and the optical resonator 23 is connected to a second port P22 through an optical fiber F22 (polarization maintaining fiber).

[0059]The optical resonator 23 generates the frequency COMB light OFC based on the laser light (center frequency ω0) that is output from the laser light source 21. The optical resonato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com