Wind turbine tower, a wind turbine, a wind turbine tower elevator and a method for assembling a wind turbine tower

a technology of wind turbines and elevators, which is applied in the direction of machines/engines, manufacturing tools, and final product manufacture, etc., can solve the problems of high specialised and expensive rolling equipment, welding reduces the fatigue limit of the tower, and the strength of the tower is affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

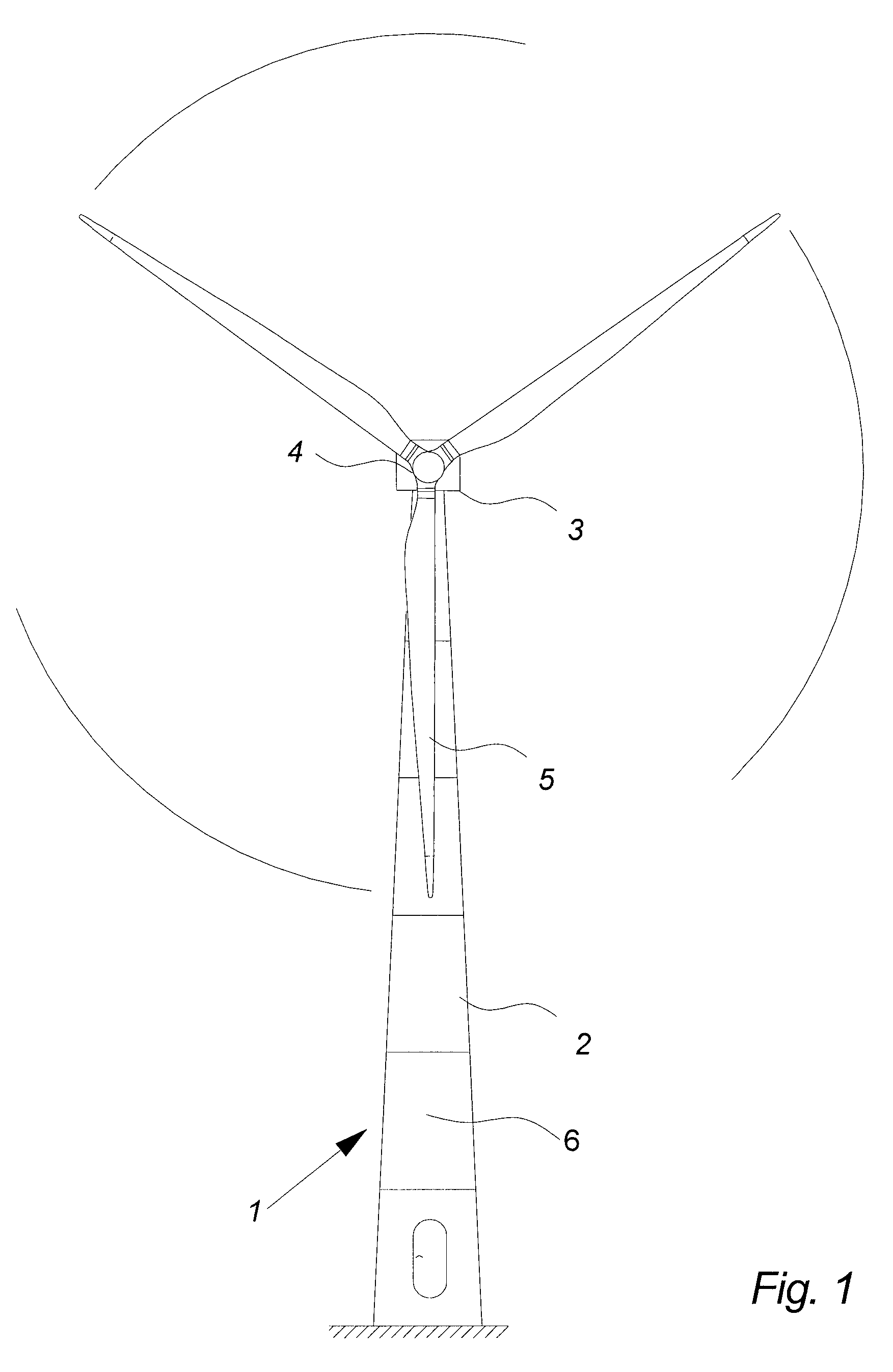

[0093]FIG. 1 illustrates a wind turbine 1 known in the art, comprising a tapered tower 2, which is subdivided into a number of tower sections 6. A wind turbine nacelle 3 is positioned on top of the tower 2.

[0094]The wind turbine rotor 4, comprising a number of wind turbine blades 5, is connected to the nacelle 3 through the low speed shaft which extends out of the nacelle 3 front.

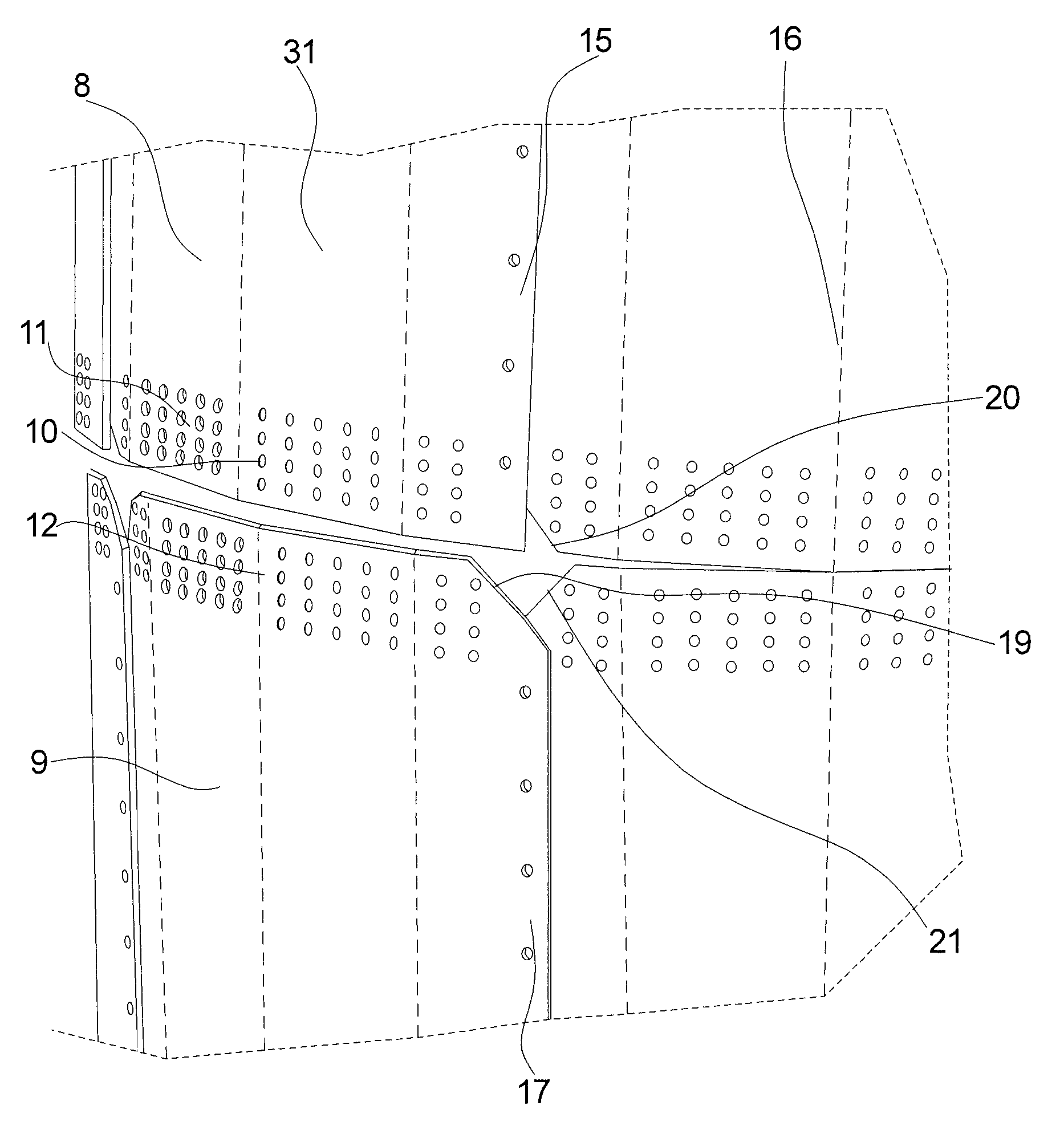

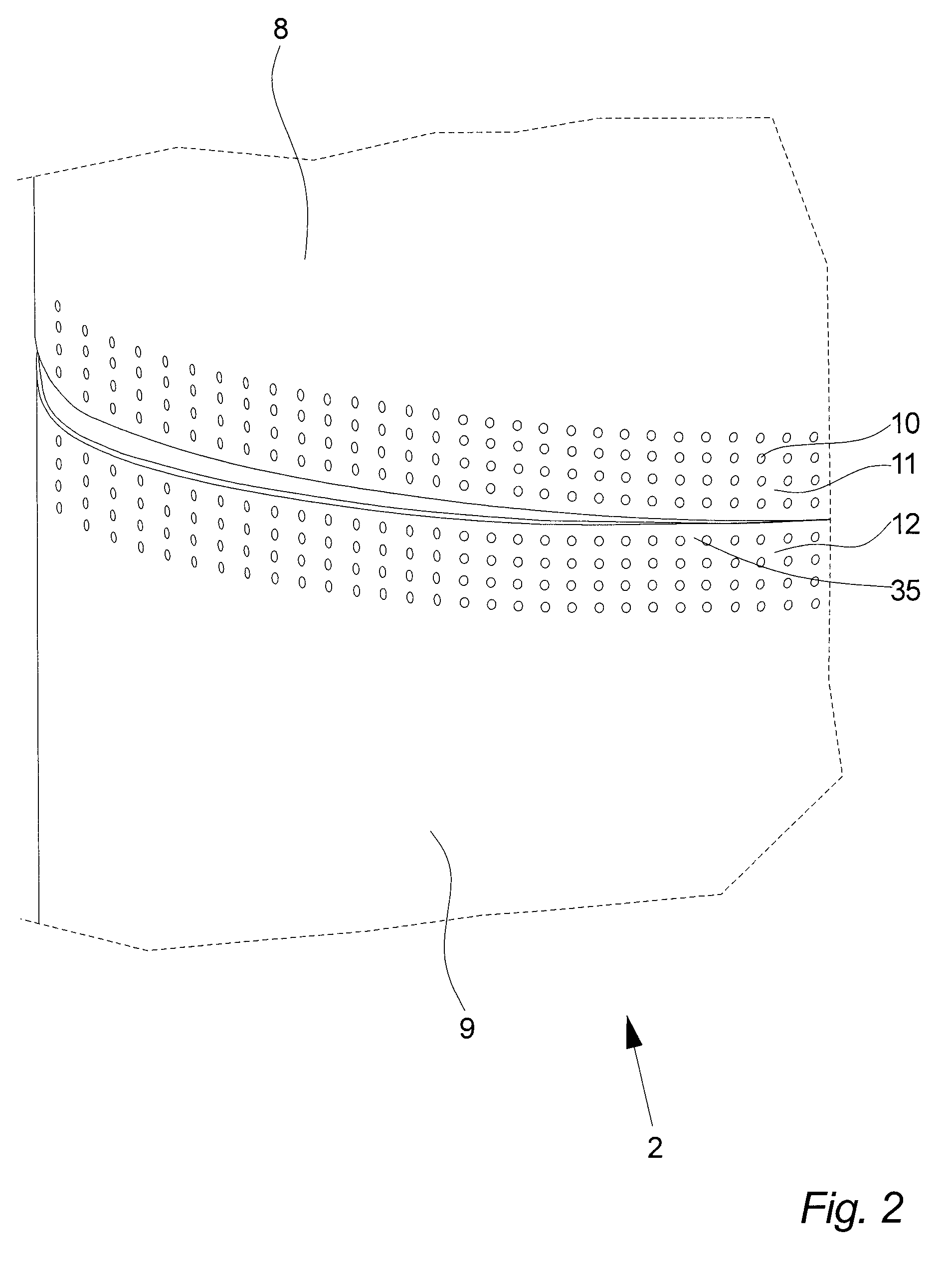

[0095]FIG. 2 illustrates a section of a wind turbine tower 2 according to the invention immediately before the assembly of two round tower rings 14, as seen in perspective. FIG. 2 shows an upper tower ring 8 on its way to be placed on a lower tower ring 9 making the bottom section 11 of the upper ring 8 overlap the top section 12 of the lower ring 9 in a horizontal overlap region 35. When the tower rings 8, 9 are in place the two rings are joined by bolting or riveting the rings 8, 9 together through the rows of bolt holes 10.

[0096]In this embodiment of the invention the tower rings 8, 9 are made as full 36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com