Mass flowmeter

a mass flowmeter and mass flow rate technology, applied in the field of mass flowmeters, can solve the problems of not being able to increase the nominal width simply, and achieve the effect of high mass flow rate and little energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

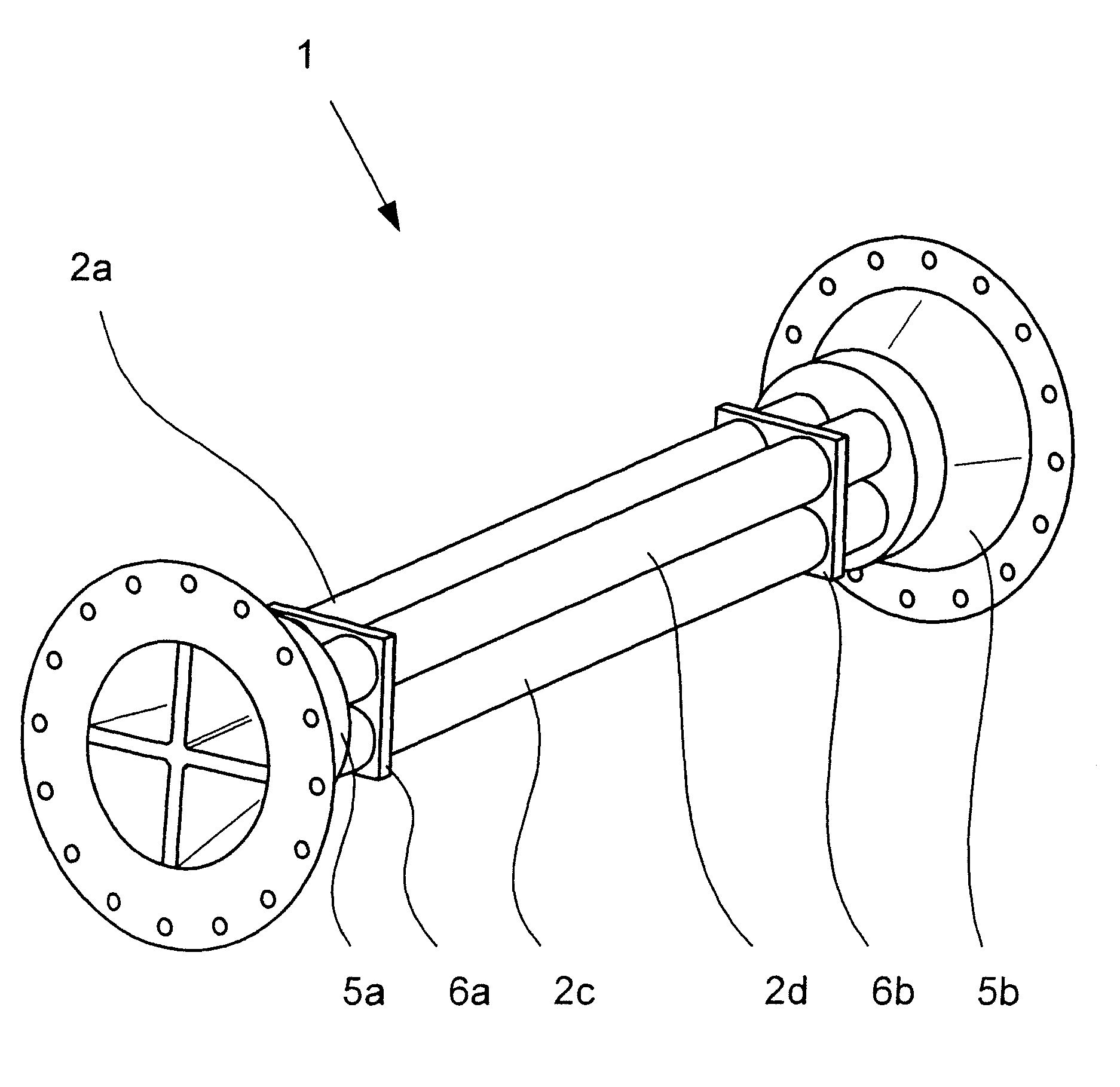

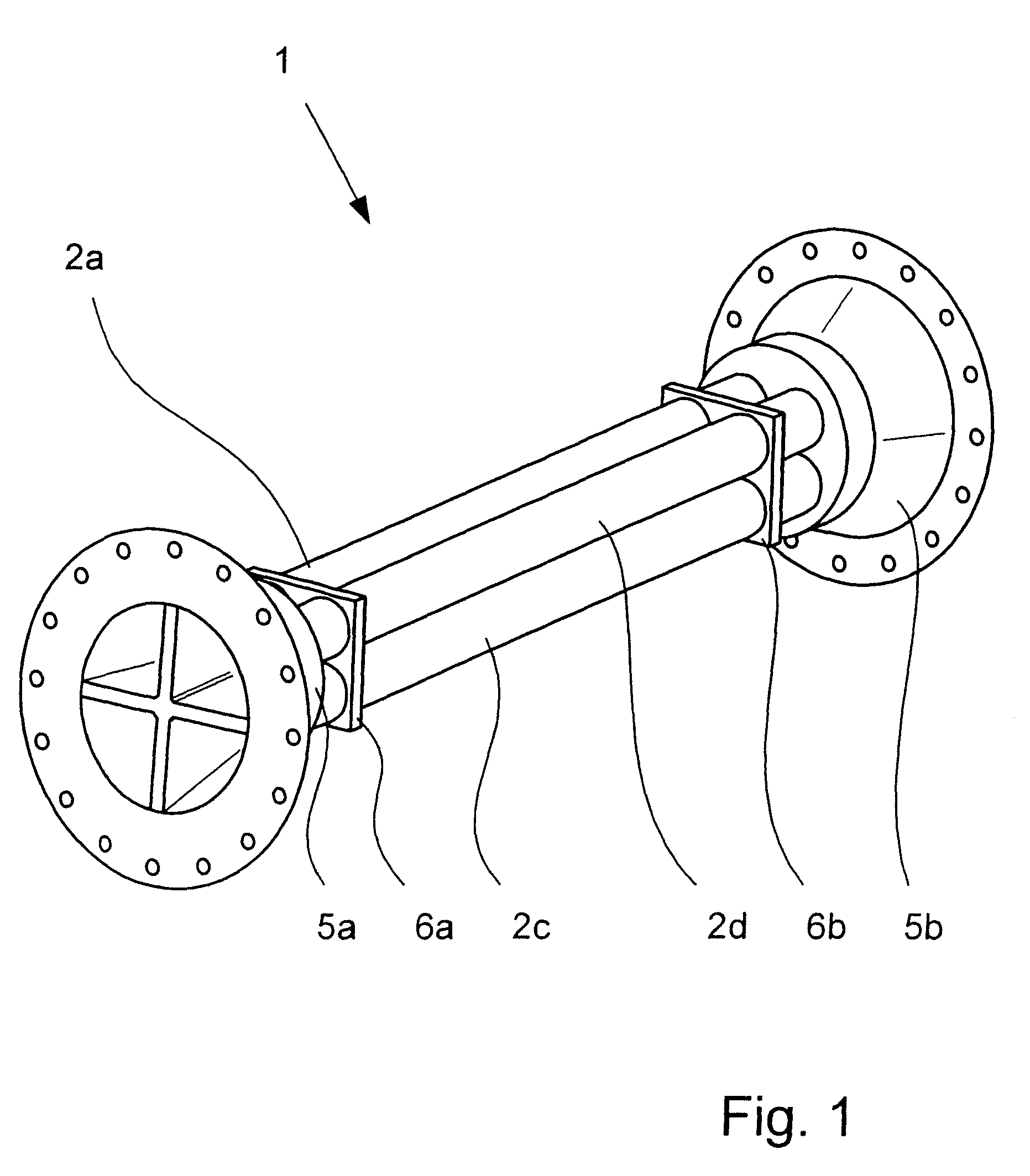

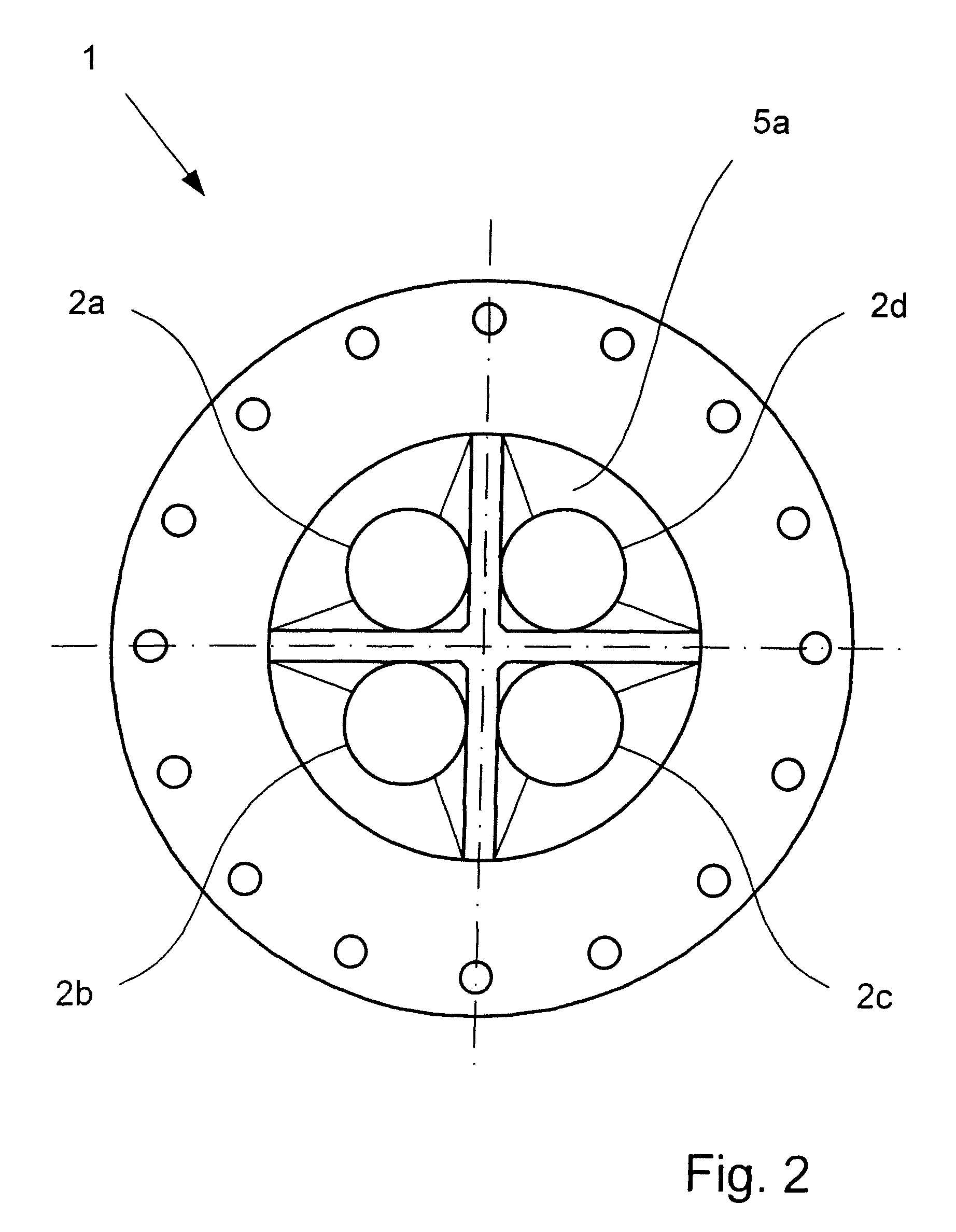

[0019]FIGS. 1 to 5 illustrate—completely or partially—mass flowmeters 1 which operate on the Coriolis principle. The figures show measurement tubes 2a, 2b, 2c, 2d through each of which a medium can flow and which can be caused to oscillate by an oscillation generator 3, in which case the excited oscillations can then be detected by oscillation sensors 4a, 4b (FIG. 3). The illustrated mass flowmeters 1 are distinguished in that not just one measurement tube 2 or two measurement tubes 2 is or are provided—as known from the prior art—but more than two measurement tubes 2 are provided, specifically a total of four measurement tubes 2a, 2b, 2c, 2d in the present case.

[0020]The plurality of measurement tubes 2a, 2b, 2c, 2d make it possible to design the mass flowmeter 1 to be very compact, since the use of a plurality of relatively small measurement tubes 2a, 2b, 2c, 2d overall leads to a larger available flow cross section without disadvantageously influencing the mechanical characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com