Vertical full premix gas steam or hot water boiler

A gas steam and hot water boiler technology, which is applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of unsatisfactory energy saving effect, low energy efficiency utilization, and insufficient compact layout, and can meet the characteristics of full premixed combustion, The effect of compact overall layout and compact boiler structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

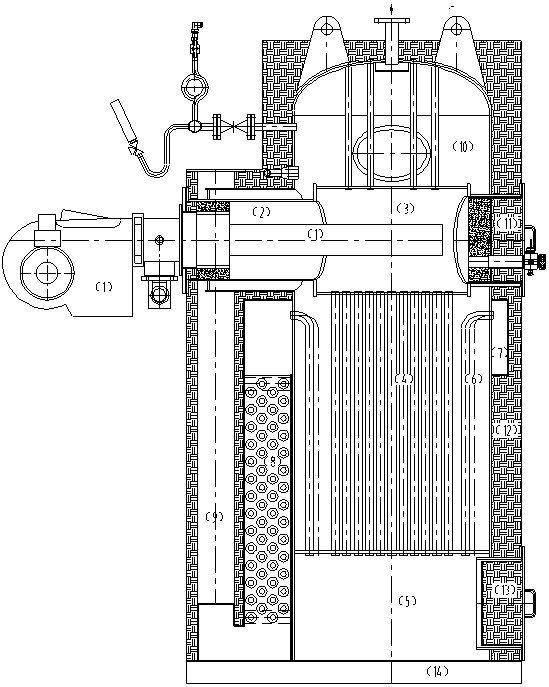

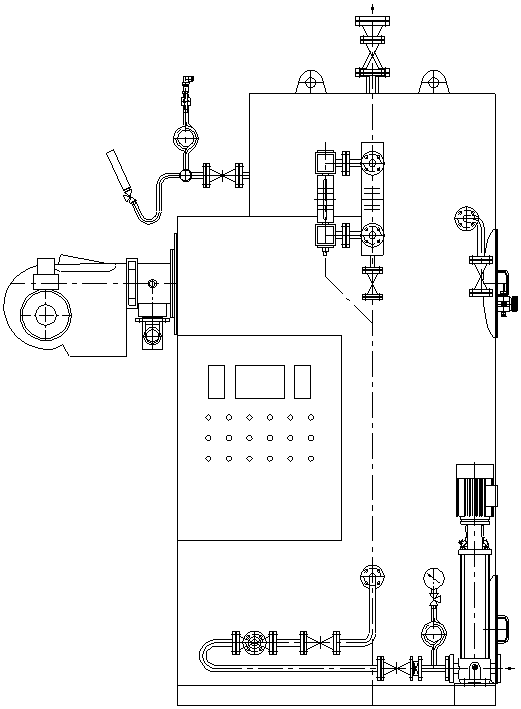

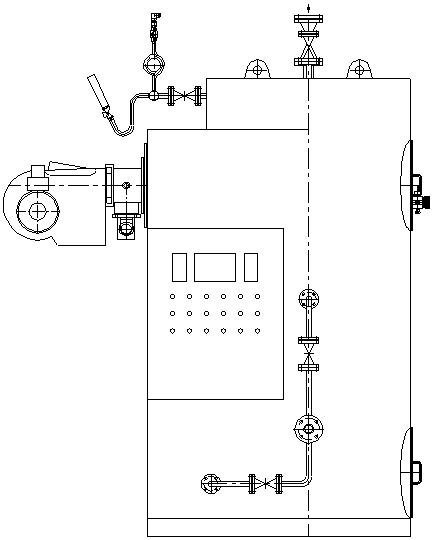

[0030] see Figure 1~4 , the present invention relates to a vertical fully premixed gas-fired steam or hot water boiler, the boiler includes a full premix burner 1 transversely connected to the vertical pot shell 10, the full premix burner 1 includes There are a racket-shaped front handle furnace 2 and a racket-shaped rear racket surface furnace 3, the racket-shaped front handle furnace 2 is located outside the vertical pot shell 10, and the racket-shaped front handle furnace 2 is wrapped with a cooling water jacket, and the racket-shaped rear portion The racket face furnace 3 is located inside the vertical pot shell 10, and the top of the vertically arranged two-pass straight smoke pipe 4 communicates with the racket-shaped rear racket face furnace 3, and the bottom of the two-pass straight smoke pipe 4 is connected to the bottom smoke box The 5 phases are connected; the racket-shaped rear racket surface furnace 3 is arranged horizontally, and the vertically arranged two-pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com