Cartridge for applying varying amounts of tissue compression

a tissue compression and cartridge technology, applied in the field of cartridges for applying varying amounts of tissue compression, can solve the problems of needless reduction of blood flow to the tissue surrounding the cut-line, decreased hemostasis time, and elevated necrosis level, so as to the degree of hemostasis, and improve the anastomotic strength. effect of degree of hemostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

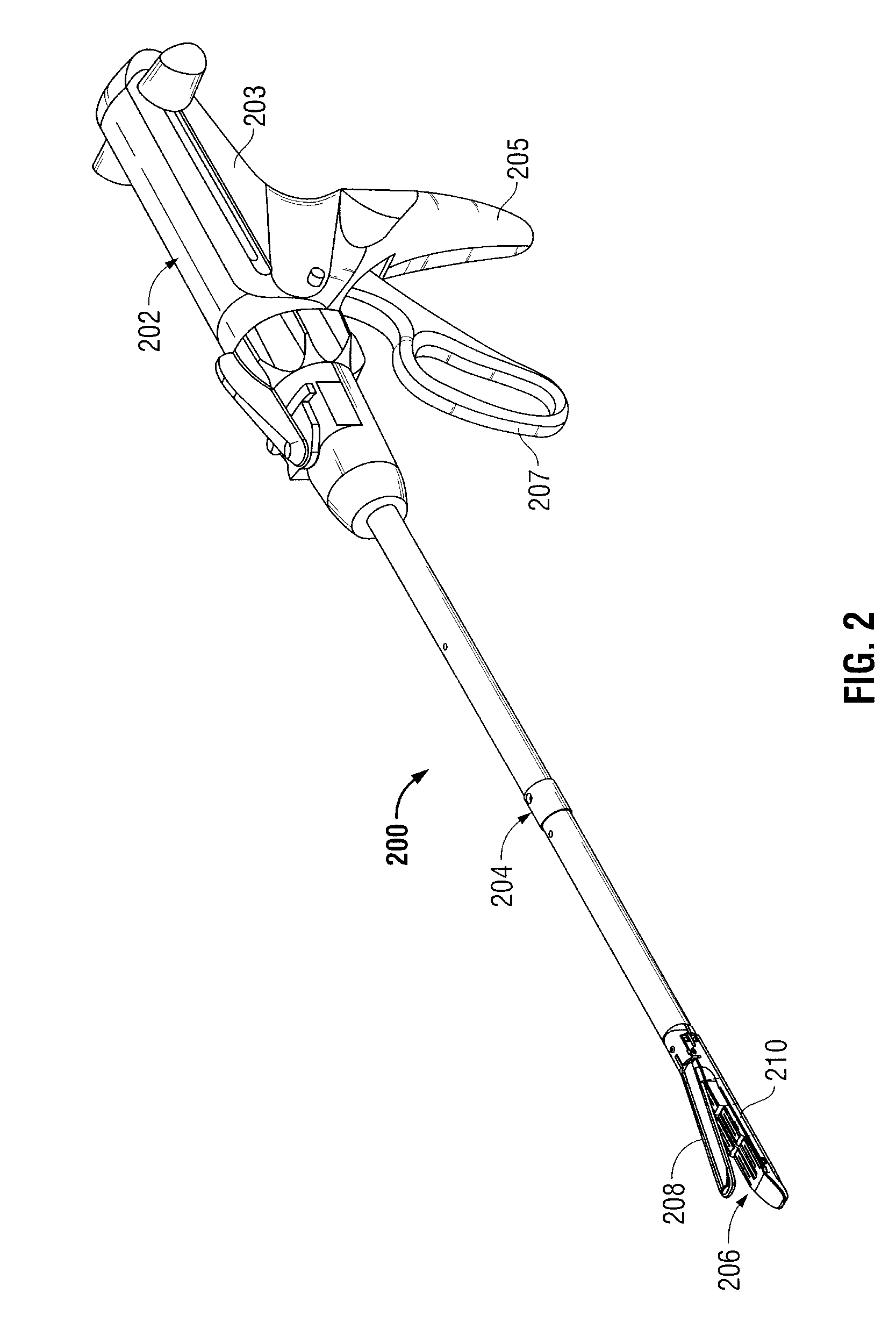

[0025]Embodiments of the presently disclosed surgical stapling instruments will now be described in detail with reference to the drawing figures wherein like reference numerals identify similar or identical elements. In the drawings and in the description which follows, the term “proximal”, as is traditional, will refer to the end of the surgical stapling instrument which is closest to the operator while the term “distal” will refer to the end of the device which is furthest from the operator.

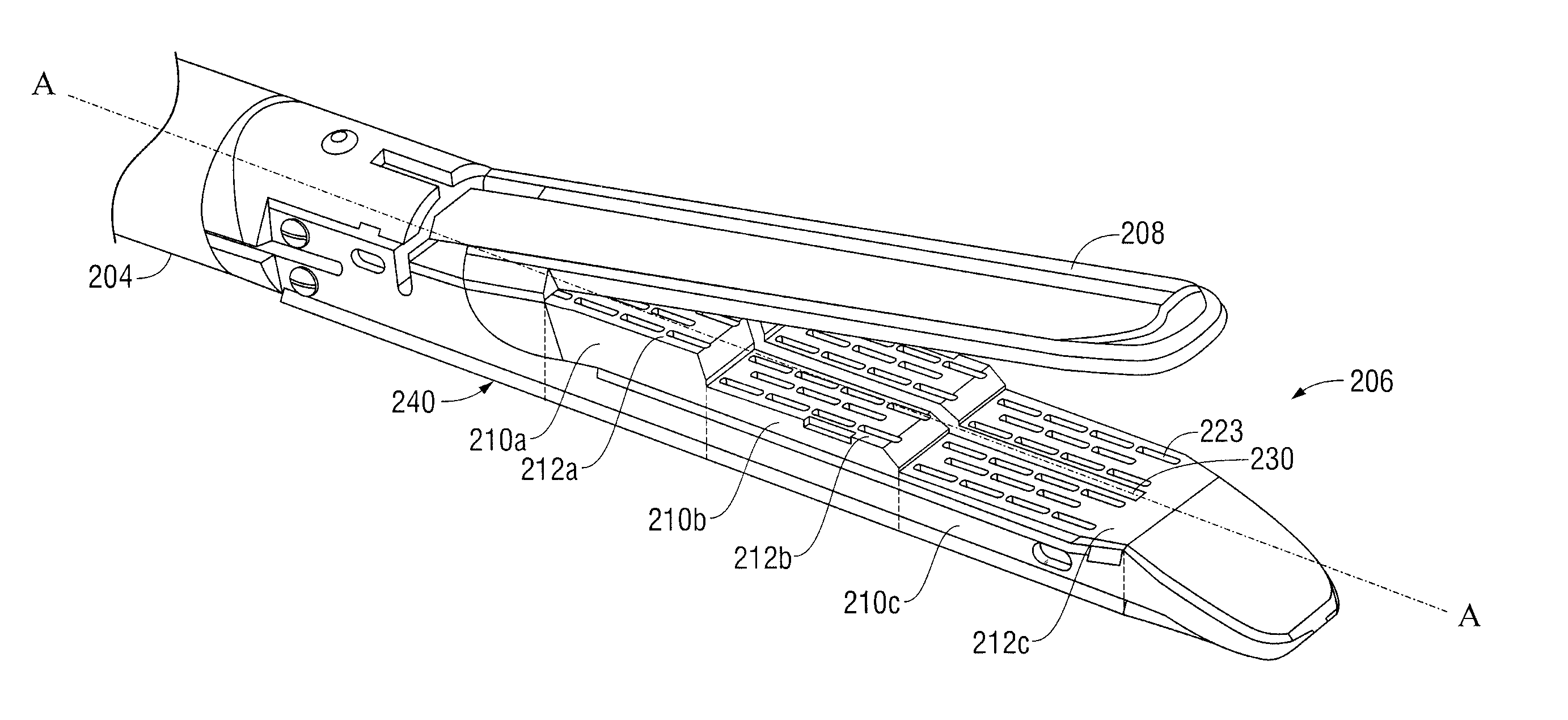

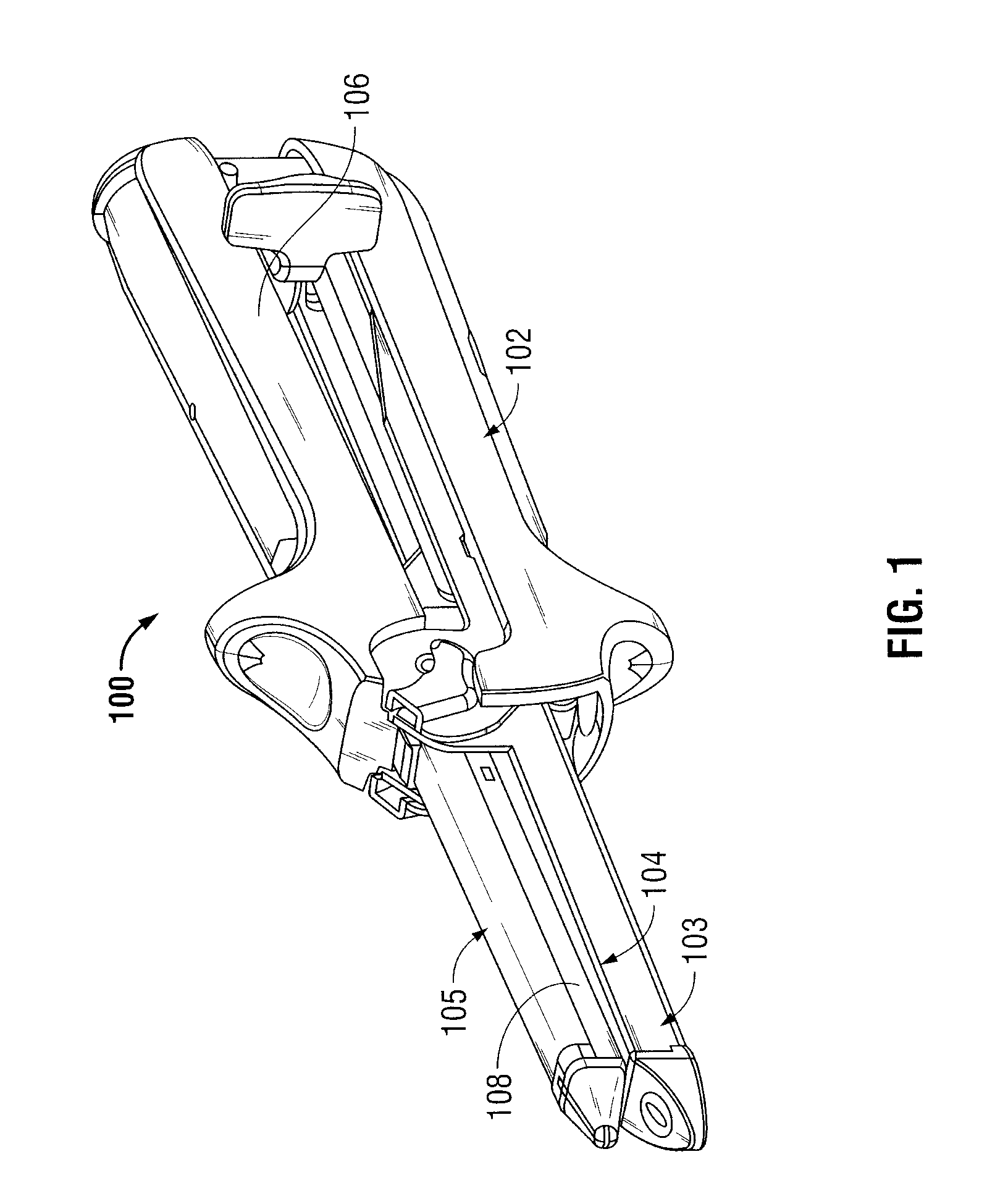

[0026]Turning now to FIG. 1, a surgical stapling instrument, of the gastrointestinal anastomosis type for performing surgical anastomotic stapling, in accordance with an embodiment of the disclosure, is generally designated as 100. Surgical stapling instrument 100 includes a first handle 102 having a jaw 103 defining a staple cartridge receiving section extending from a distal end thereof, a staple cartridge 104 receivable in jaw 103, a second handle 106 having a jaw 105 defining an anvil membe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com