Mounting clip with improved noise vibration and harshness damping

a technology of noise vibration and damping, which is applied in the direction of machine supports, manufacturing tools, other domestic articles, etc., can solve the problems of unsatisfactory noise and/or vibration, nvh—noise, vibration and harshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

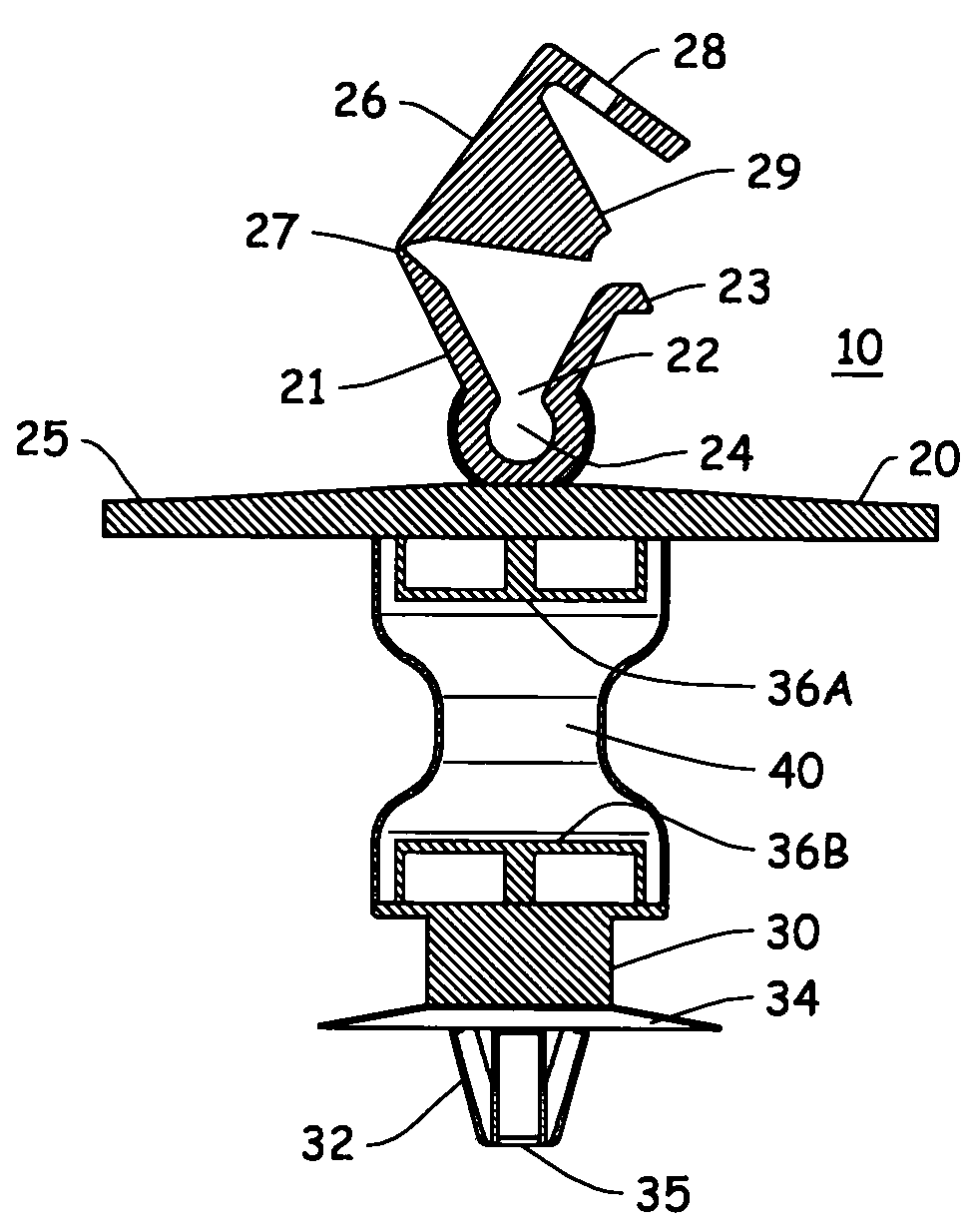

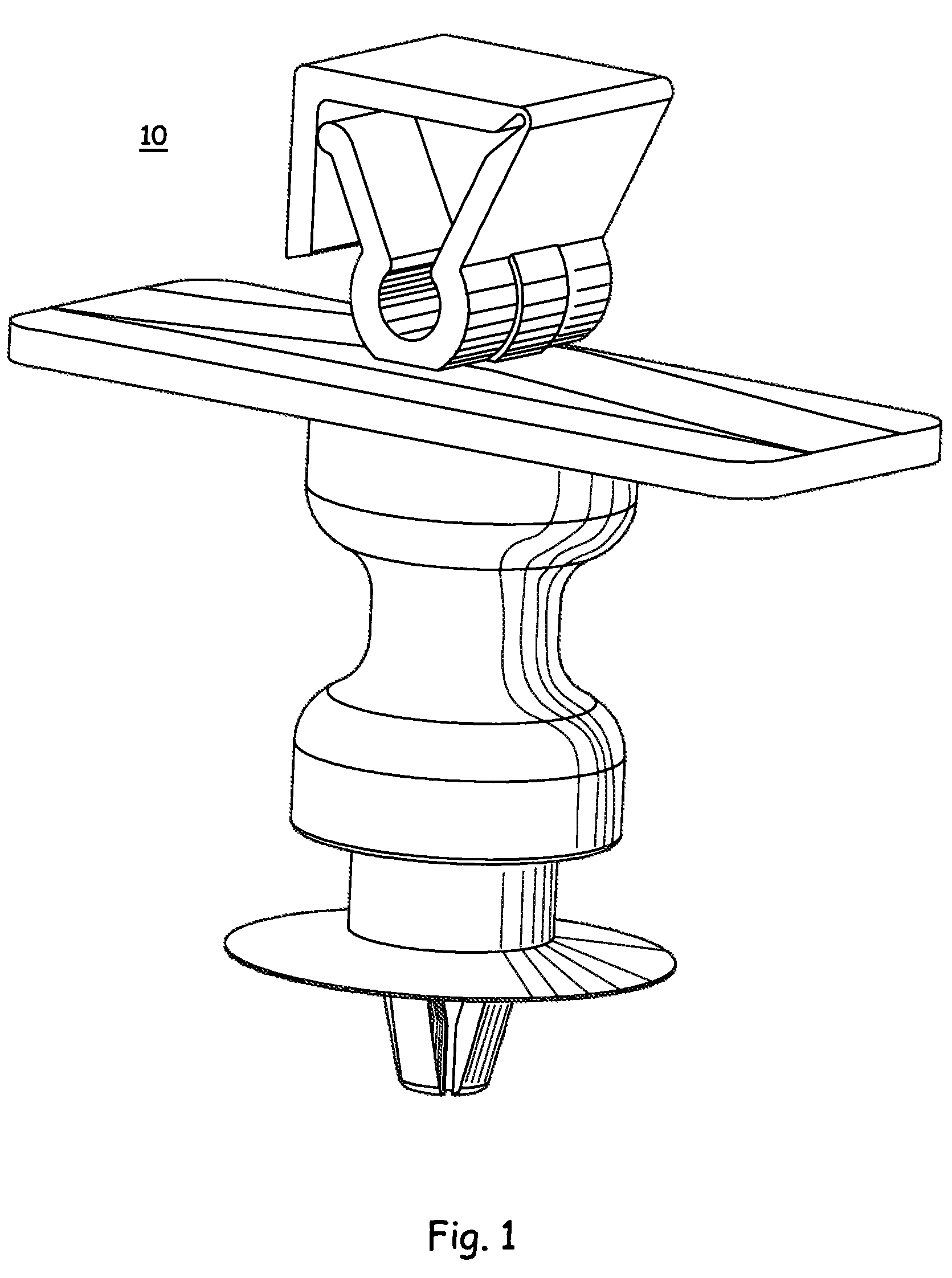

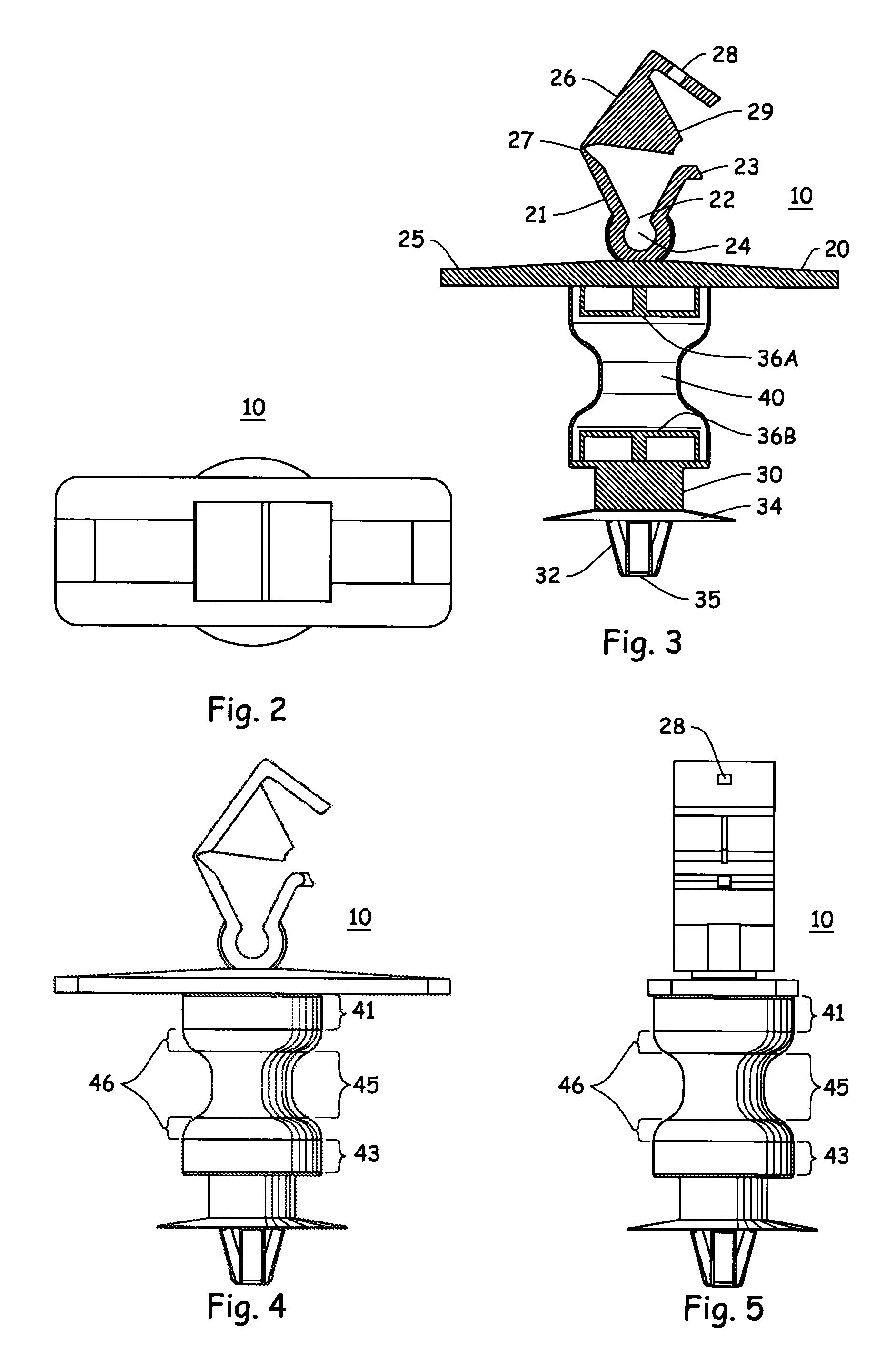

[0017]As illustratively depicted in FIGS. 1-6 (1-5 of the clip and 6 in the installed position), the present invention is directed at an improved clip used to reduce the NVH exhibited by the respective mating components.

[0018]It is contemplated that the present invention includes a clip 10 comprising a multi-piece assembly. This clip assembly 10 preferably includes a first clip portion 20, a second clip portion 30 and a connectively spanning middle clip portion 40.

[0019]The first portion 20 may be adapted to attach to a wire-like structure 50 (e.g. a wire suspension as found on some automotive seats). This first portion 20 may be constructed of any relatively ridged material, but is preferably plastic. The first portion 20 includes a wall portion 21 that includes a constricted neck 22 (which may depend from a portion that includes a tang 23 as shown, or a hole) adjoining a cavity 24 into which a wire can be snap fit. The first portion may also include a locking cover 26. As shown, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Tensile Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com