Vehicle interior noise testing road surface, laying method of vehicle interior noise testing road surface, and vehicle interior noise testing method

A technology of vehicle interior noise and test method, which is applied in the field of automobiles, can solve problems such as accelerated vehicle interior noise testing, inability to fully stimulate low-frequency noise in the vehicle, and unsuitability for vehicle noise testing, so as to achieve more competitiveness and improve NVH levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

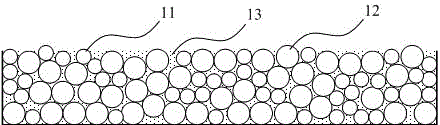

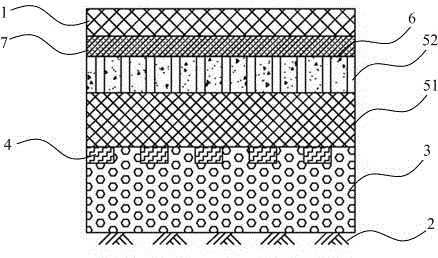

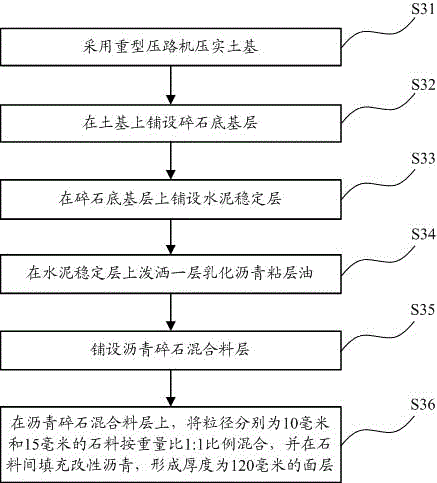

[0033] Please refer to figure 1 As shown, Embodiment 1 of the present invention provides a road surface for vehicle interior noise testing, including a surface layer 1 with a thickness of 120 mm, which includes particles mixed in a weight ratio of 1:1, with particle sizes of 10 mm and 15 mm respectively. The stone materials 11 and 12 are filled with modified asphalt 13 between the stone materials. Specifically, the particle size of the stone 11 is 10 mm, the particle size of the stone 12 is 15 mm, and the weight ratio of the stone 11 to the stone 12 is 1:1.

[0034] The surface layer 1 has a porosity of 4.0% and a construction depth of 4.8 mm. In addition, comprehensively considering the laying cost and testing convenience, the paving width of the test road in this embodiment is 3 meters, and the paving length is 180-200 meters, preferably 200 meters. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com