Method, device, equipment and storage medium for controlling engine shutdown

A control method and engine technology, applied in the field of vehicles, can solve the problems of complex control of three motors, high difficulty and high requirements for clutch control, and achieve the effect of improving the NVH level of the whole vehicle and quickly stopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

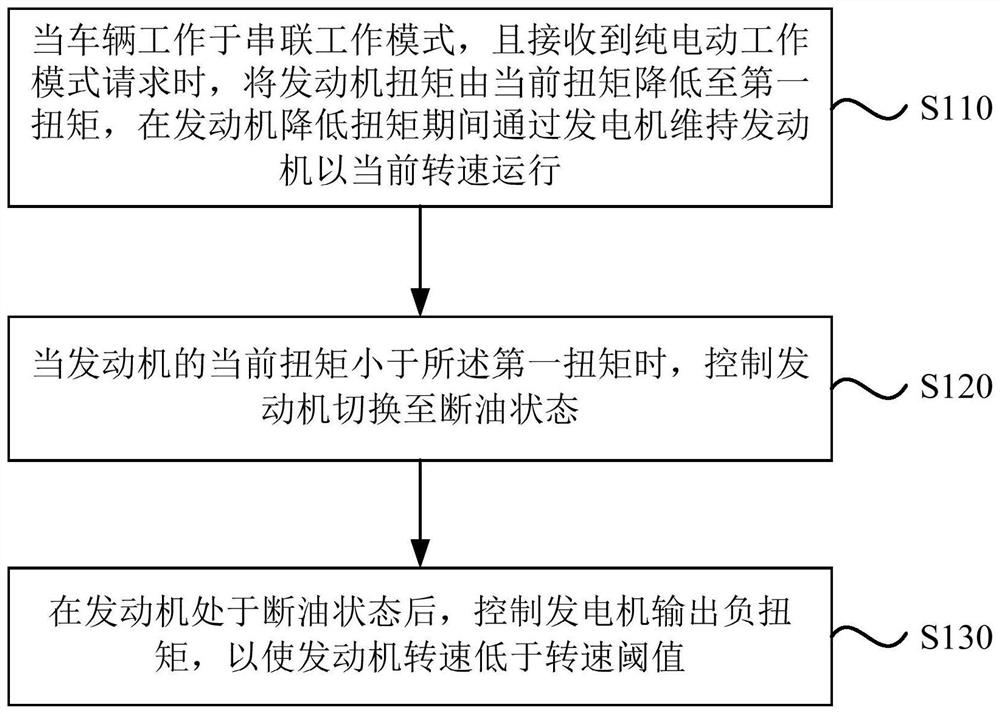

[0043] figure 1 It is a flow chart of an engine shutdown control method provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of engine shutdown control. The method can be executed by the engine shutdown control device in the embodiment of the present invention. The device can adopt implemented in software and / or hardware, such as figure 1 As shown, the method specifically includes the following steps:

[0044] S110. When the vehicle is working in the series working mode and a pure electric working mode request is received, reduce the engine torque from the current torque to the first torque, and maintain the engine at the current speed operation.

[0045] Wherein, the way to maintain the engine running at the current speed through the generator during the torque reduction of the engine may be to maintain the engine running at the current speed through the generator outputting negative torque, or to maintain the engine running at t...

Embodiment 2

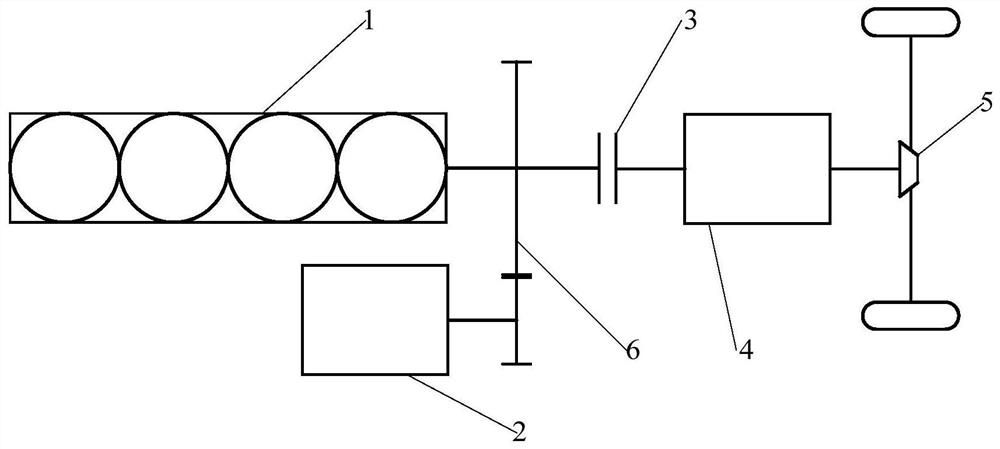

[0083] figure 2 It is a schematic structural diagram of an engine shutdown control device provided in Embodiment 2 of the present invention. This embodiment is applicable to the situation of engine shutdown control, and the device can be realized by software and / or hardware, and the device can be integrated in any device that provides engine shutdown control functions, such as figure 2 As shown, the engine shutdown control device specifically includes: a first control module 210 , a second control module 220 and a third control module 230 .

[0084] Wherein, the first control module is used for reducing the engine torque from the current torque to the first torque when the vehicle is working in the series working mode and receiving the request of the pure electric working mode. maintain the engine running at the current speed;

[0085] A second control module, configured to control the engine to be in a fuel-cut state when the actual torque of the engine is less than the f...

Embodiment 3

[0090] image 3 It is a schematic structural diagram of a computer device in Embodiment 3 of the present invention. image 3 A block diagram of an exemplary computer device 12 suitable for implementing embodiments of the invention is shown. image 3 The computer device 12 shown is only an example, and should not impose any limitation on the functions and scope of use of the embodiments of the present invention.

[0091] Such as image 3 As shown, computer device 12 takes the form of a general-purpose computing device. Components of computer device 12 may include, but are not limited to, one or more processors or processing units 16 , system memory 28 , bus 18 connecting various system components including system memory 28 and processing unit 16 .

[0092] Bus 18 represents one or more of several types of bus structures, including a memory bus or memory controller, a peripheral bus, an accelerated graphics port, a processor, or a local bus using any of a variety of bus struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com