Machining technology for automotive transmission gear

A technology of automobile transmission and processing technology, which is applied in the field of automobile transmission, can solve problems such as production difficulties, transmission abnormal noise, durable life, and many iron filings, so as to improve gear meshing accuracy, reduce transmission error value, and enhance enterprise competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

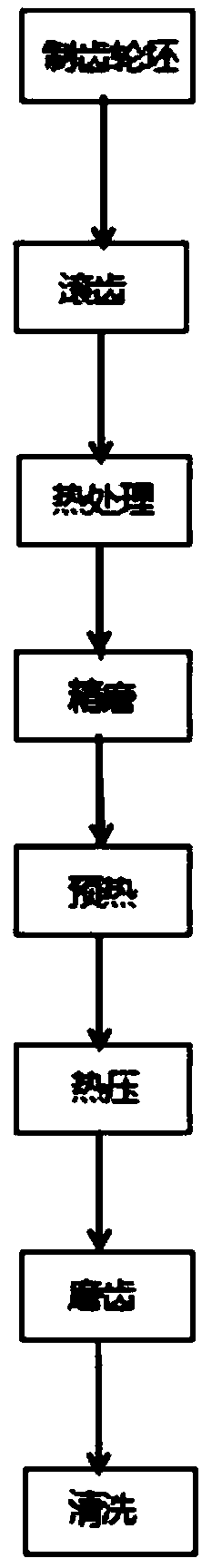

[0031] See attached figure 1 , the present embodiment provides a kind of automobile transmission gear processing technology, and its steps are:

[0032] a. Gear blank: use hot die forging to make the blank, turn the outer circle, end face and inner hole, reserve 3~5mm machining allowance, and the overall roughness reaches Ra6.3;

[0033] b. Gear hobbing: The teeth of the gear are processed by a gear hobbing machine, and the surface roughness reaches Ra3.2;

[0034] c. Heat treatment: Carburizing and quenching the gears;

[0035] d. Fine grinding: the inner hole and end face of the gear are finely ground, and the surface roughness of the gear tooth end face and inner hole reaches Ra1.6;

[0036] e. Preheating: heat the gear spline to 120° and keep it warm for 30 seconds;

[0037] f. Axis selection;

[0038] g. Hot pressing: use the servo press machine to vertically press the gear and the shaft in a hot state; the gear and the shaft have an interference fit with a large diam...

Embodiment 2

[0059]Embodiment 2: be the preferred embodiment of embodiment 1

[0060] See attached figure 1 , the present embodiment provides a kind of processing technology of automobile transmission gear and gear shaft assembly, and its steps are:

[0061] a. Gear blank: use hot die forging to make the blank, turn the outer circle, end face and inner hole, reserve 3~5mm machining allowance, and the overall roughness reaches Ra6.3;

[0062] b. Gear hobbing: The teeth of the gear are processed by a gear hobbing machine, and the surface roughness reaches Ra3.2;

[0063] c. Heat treatment: Carburizing and quenching the gears;

[0064] d. Fine grinding: the inner hole and end face of the gear are finely ground, and the surface roughness of the gear tooth end face and inner hole reaches Ra1.6;

[0065] e. Preheating: heat the gear spline to 120° and keep it warm for 30 seconds;

[0066] f. Axis selection;

[0067] g. Hot pressing: use the servo press machine to vertically press the gear a...

Embodiment 3

[0091] See attached figure 1 , the present embodiment provides a kind of automobile transmission gear processing technology, and its steps are:

[0092] a. Gear blank: use hot die forging to make the blank, turn the outer circle, end face and inner hole, reserve 3~5mm machining allowance, and the overall roughness reaches Ra6.3;

[0093] a1. Normalizing the gear, in order to obtain the hardness suitable for the subsequent cutting process and prepare for the final heat treatment, the normalizing treatment of the gear can effectively reduce the heat treatment deformation;

[0094] a2. CNC lathes are used to process the aperture and end face of the gear to ensure the perpendicularity between the inner hole and the end face;

[0095] b. Gear hobbing: The teeth of the gear are processed by a gear hobbing machine, and the surface roughness reaches Ra3.2;

[0096] c. Heat treatment: Carburizing and quenching the gears;

[0097] d. Fine grinding: the inner hole and end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com