Methods for improving the productivity of oil producing wells

a technology for oil producing wells and productivity, applied in the field of methods for improving the productivity of oil producing wells, can solve the problems of decreasing the relative permeability of oil, reducing the productivity of wells, and conventional treatments for increasing the hydrocarbon production of such wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

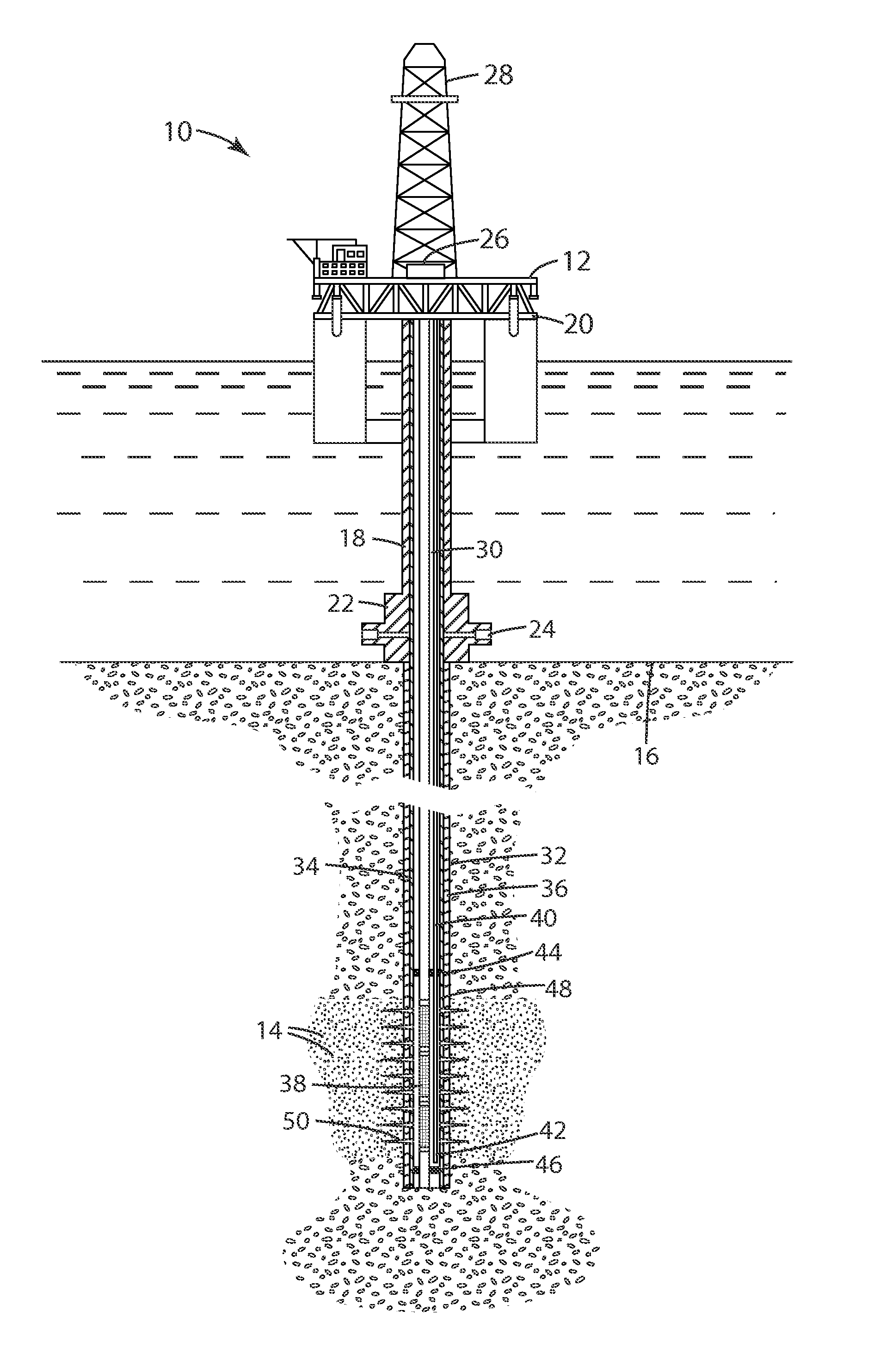

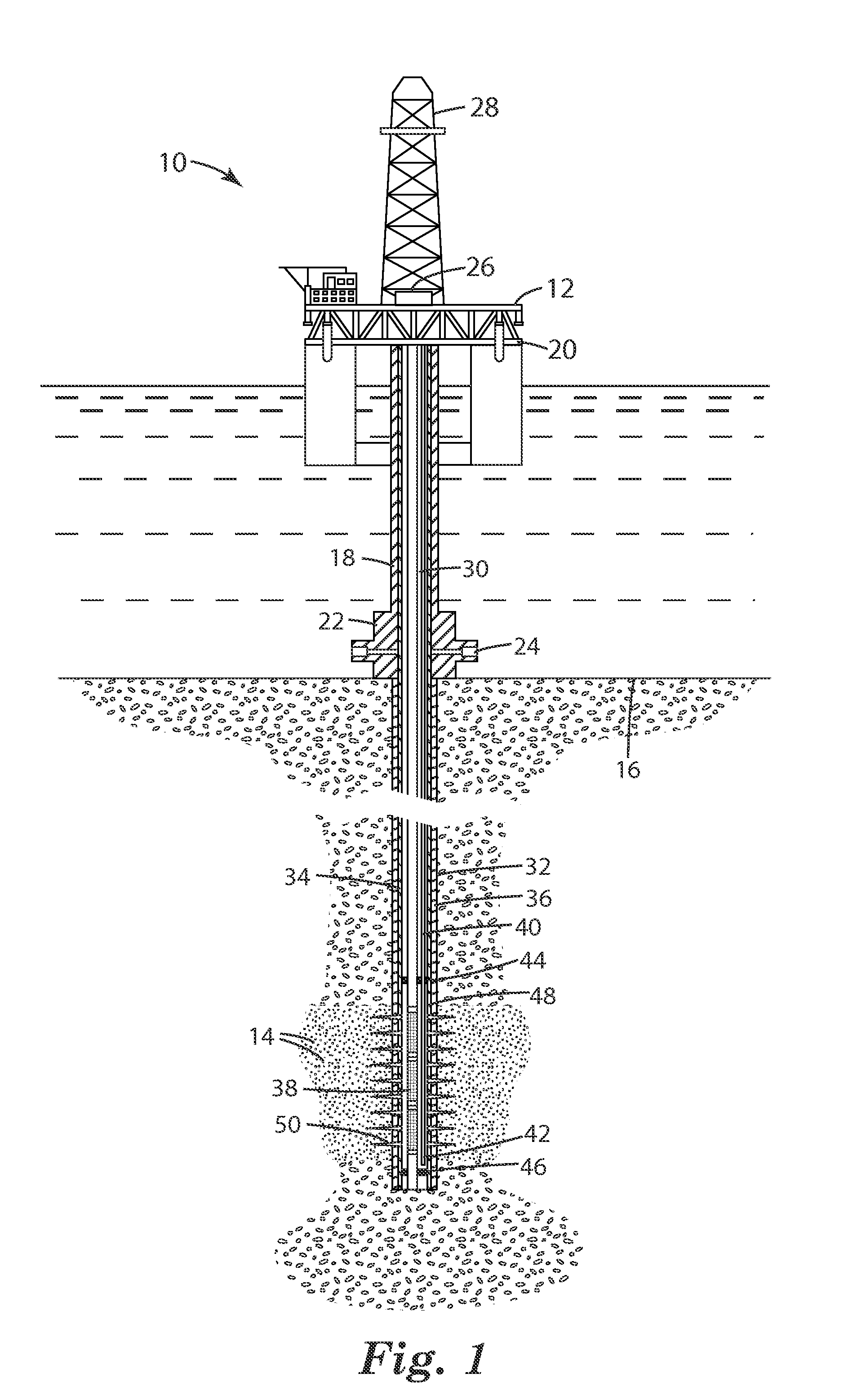

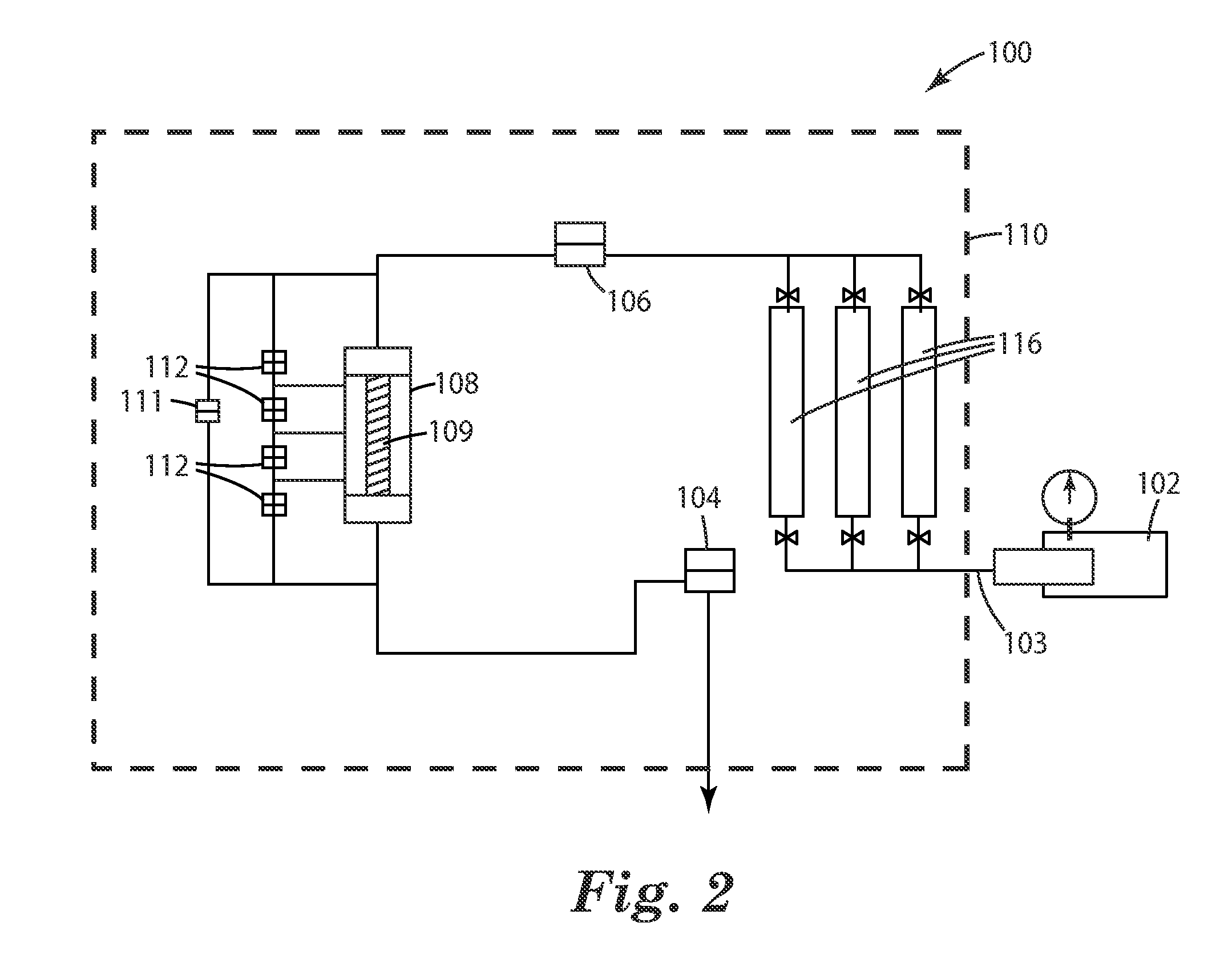

Image

Examples

examples

[0132]The following abbreviations are used in the examples.

[0133]qpump is the flow rate of the pump

[0134]qtotal—core is the flow rate of combined gas and oil through the core

[0135]qg—core is the flow rate of gas through the core

[0136]go—core is the flow rate of oil through the core

[0137]ΔP is the pressure drop across the core

[0138]krg is the gas relative permeability

[0139]kro is the oil relative permeability

[0140]Nc is the capillary number

[0141]Nonionic Polymer:

[0142]Nonionic Polymer 1 was prepared essentially as in Examples 2A, 2B, and 4 of U.S. Pat. No. 6,664,354 (Savu), incorporated herein by reference, except using 4270 kilograms (kg) of N-methylperfluorobutanesulfonamidoethanol, 1.6 kg of phenothiazine, 2.7 kg of methoxyhydroquinone, 1590 kg of heptane, 1030 kg of acrylic acid, 89 kg of methanesulfonic acid (instead of triflic acid), and 7590 kg of water in the procedure of Example 2B and using 15.6 grams of 50 / 50 mineral spirits / TRIGONOX-21-050 organic peroxide initiator (tert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com