Transporting apparatus and printer using the same

a technology of transporting equipment and printing machine, which is applied in the directions of transportation, packaging, thin material processing, etc., can solve the problems of poor relative position accuracy, denting of the medium, and affecting the transporting of the transporting medium, so as to improve the relative position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

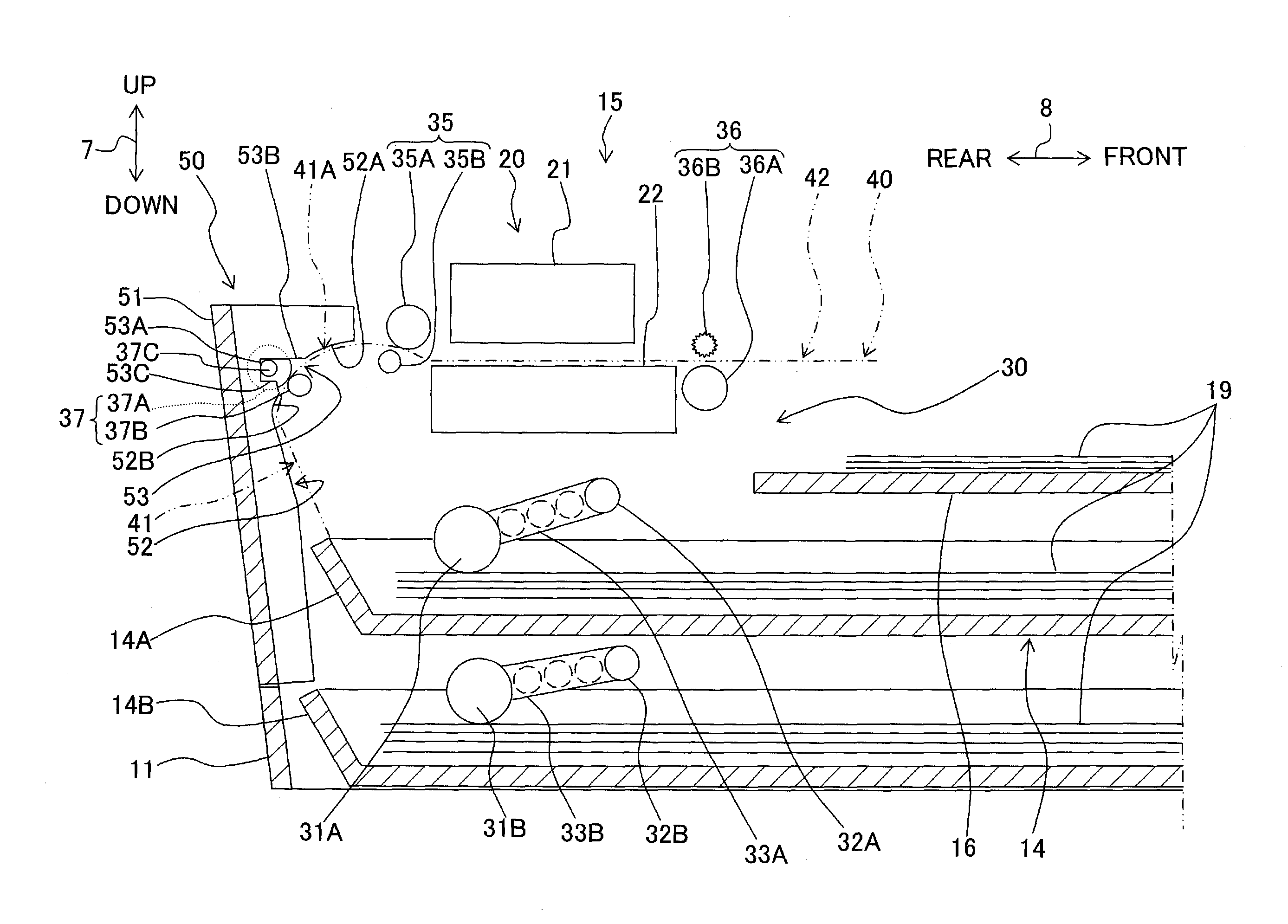

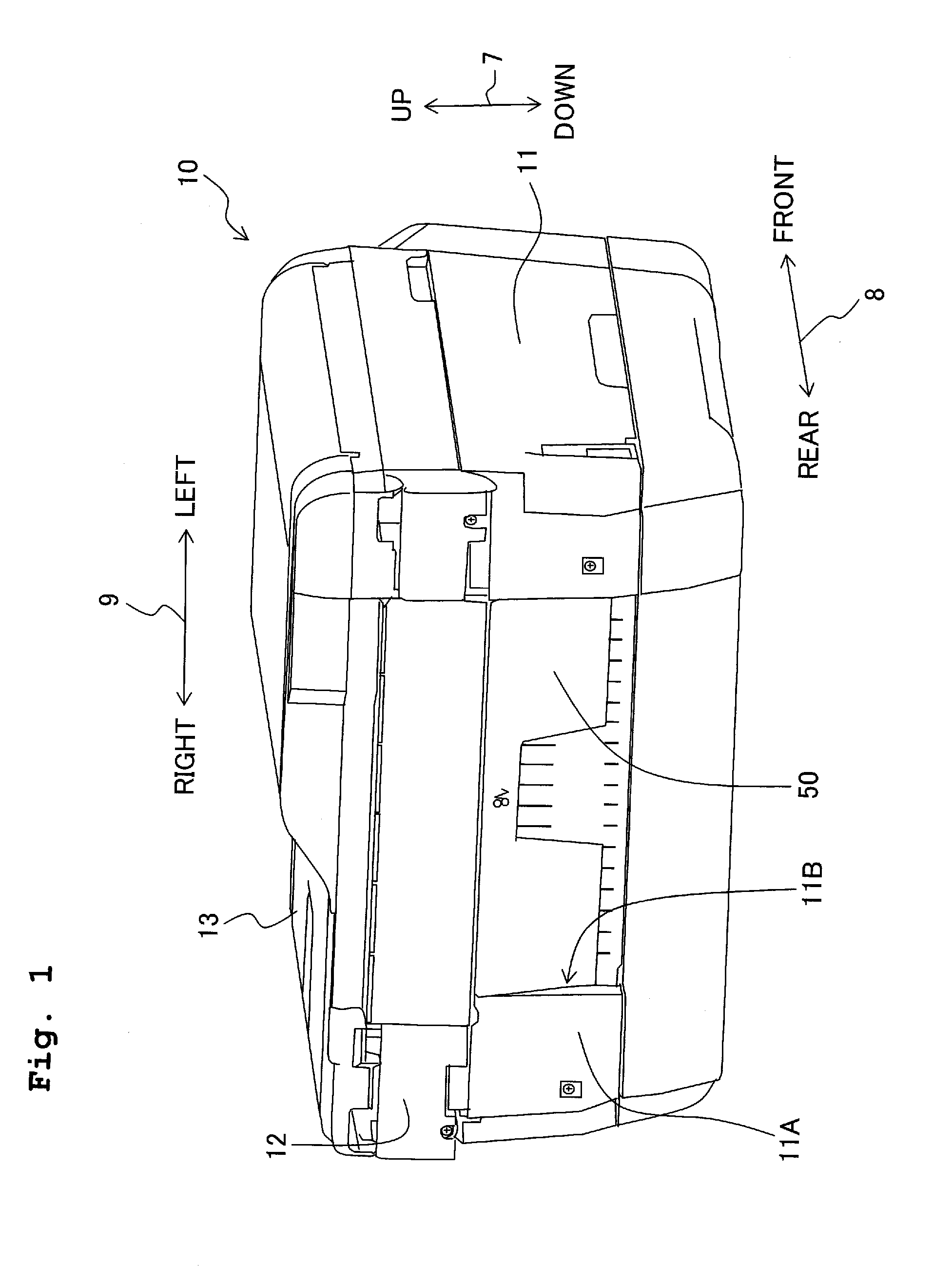

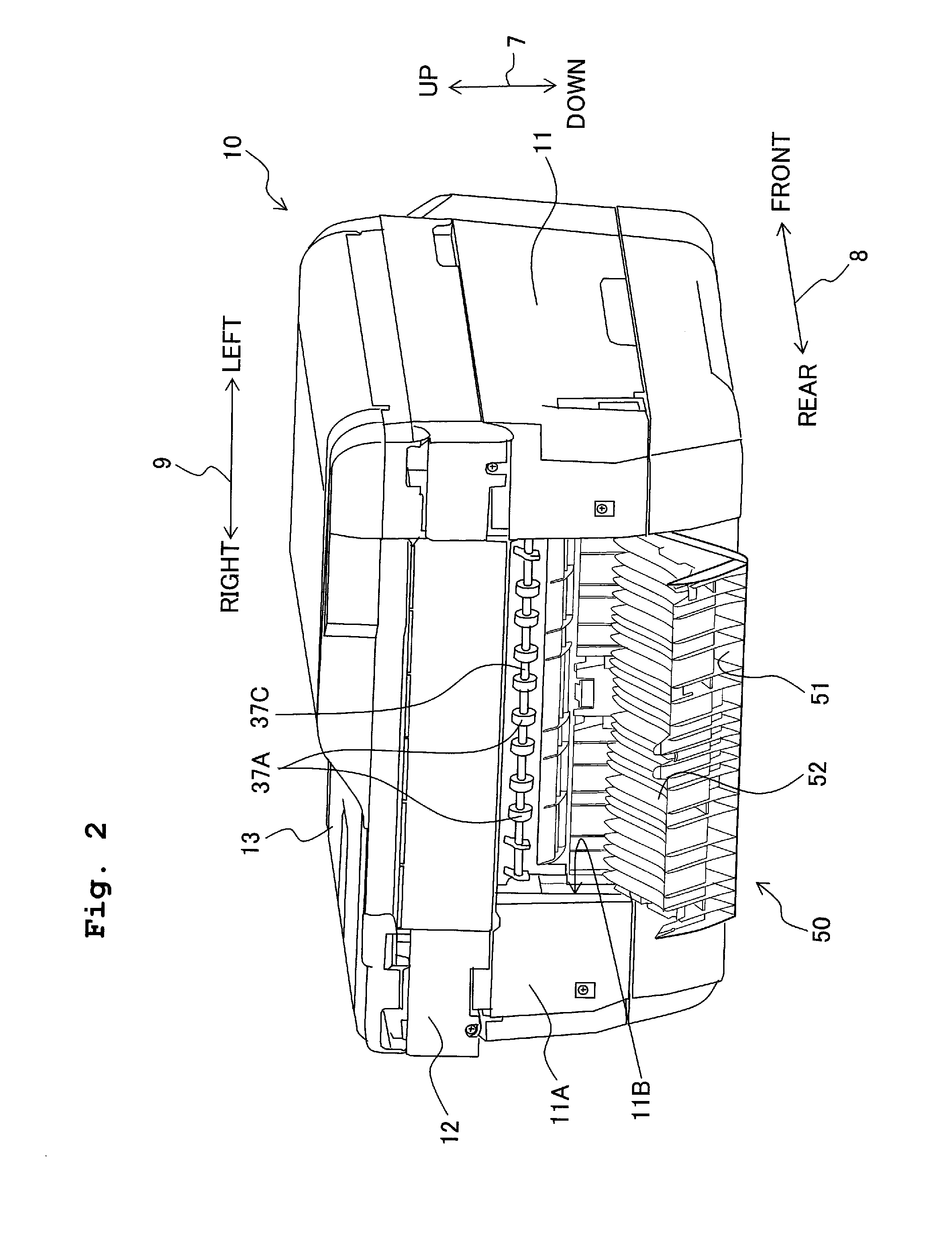

Method used

Image

Examples

first modified embodiment

[0080]An arrangement in which the movable member 50 is positioned by the engaging portion 54 and the notch 53 has been described above. However, in a first modified embodiment, an arrangement in which the movable member 50 is positioned by an engaging portion 55 as shown in FIG. 7 instead of the engaging portion 54 and the notch 53 will be described. The engaging portion 55 is formed to be C-shaped with a part of a ring notched out, and is provided at a position at which the shaft 37C is press-fitted when the attitude of the movable member 50 changes from the second attitude to the first attitude.

[0081]The engaging portion 55 positions the movable member 50 with respect to the shaft 37C when the peripheral surface of the shaft 37C makes a contact with an inner peripheral surface. Then the engaging portion 55 latches the movable member 50 with the shaft 37C. The rotatable shaft 37C makes a sliding contact with the inner peripheral surface of the engaging portion 55. In other words, t...

second modified embodiment

[0082]An arrangement in which the claw portion 54B is hitched on the shaft 37C by the snap-fit has been described above. However, an arrangement in which the claw portion 54B is movably supported in the vertical direction 7 by using an elastic member such as a coil spring or a plate spring shown in FIG. 8, and the claw portion 54B is hitched on the shaft 37C may be used.

[0083]In FIG. 8, the claw portion 54B is fixed to the other end of the plate spring 57 of which one end is fixed to the base portion 51 of the movable member 50, and is supported by the plate spring 57 to be movable in the vertical direction 7 in the first attitude, and also is biased upward in the first attitude. The plate spring 57 and the claw portion 54B correspond to the deformable portion of the present teaching.

[0084]In the embodiment and the modified embodiments described above, the transporting medium 19 which is transported in a substantially vertical direction is directed in a substantially horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com