Virtual image display device and manufacturing method of virtual image display device

a virtual image and display device technology, applied in the direction of television systems, planar/plate-like light guides, instruments, etc., can solve the problems of deterioration of light guide performance or the like, and achieve the effect of suppressing damage and soiling on surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

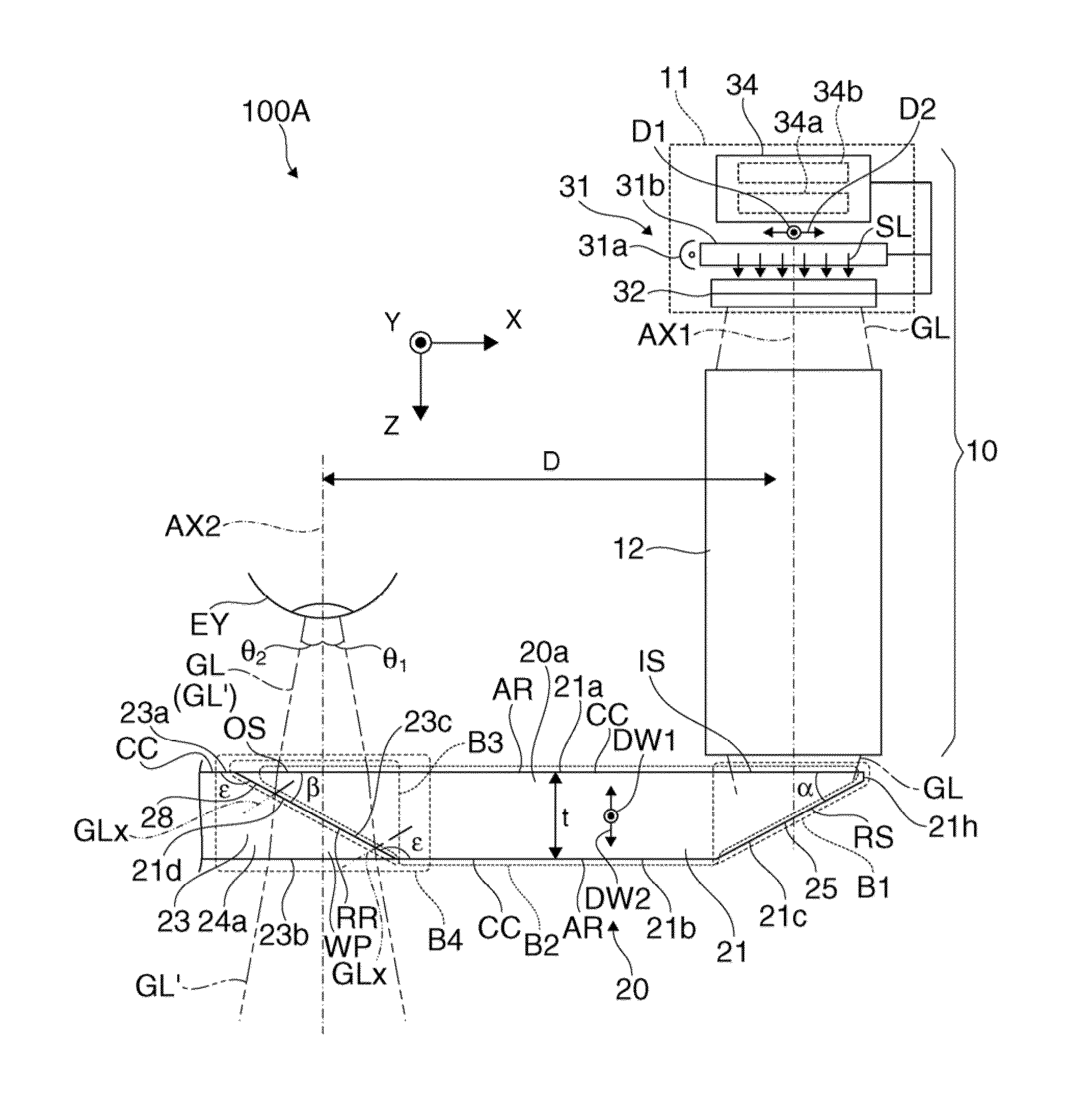

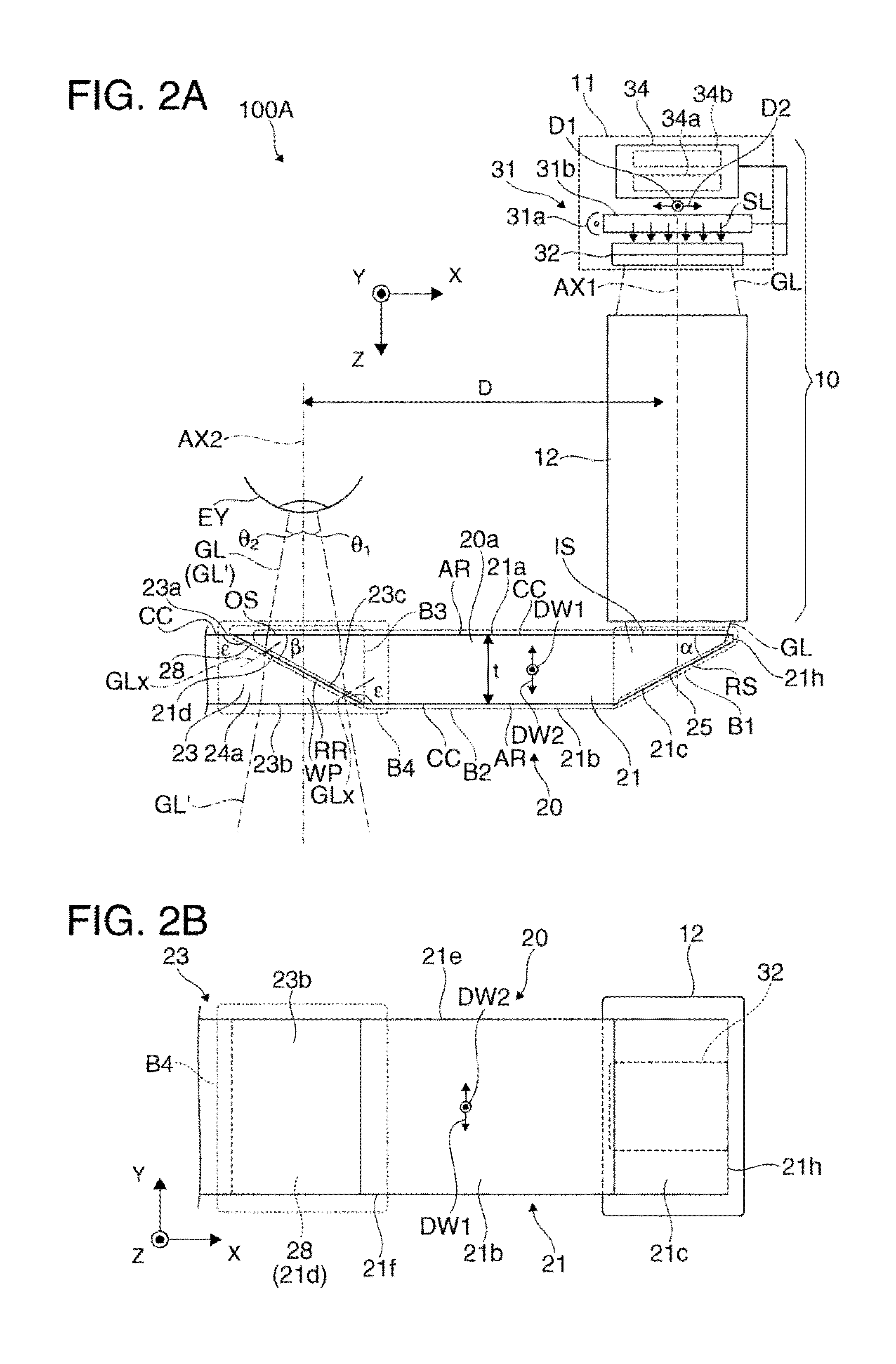

[0038]As below, a virtual image display device according to the first embodiment of the invention will be explained in detail with reference to the drawings.

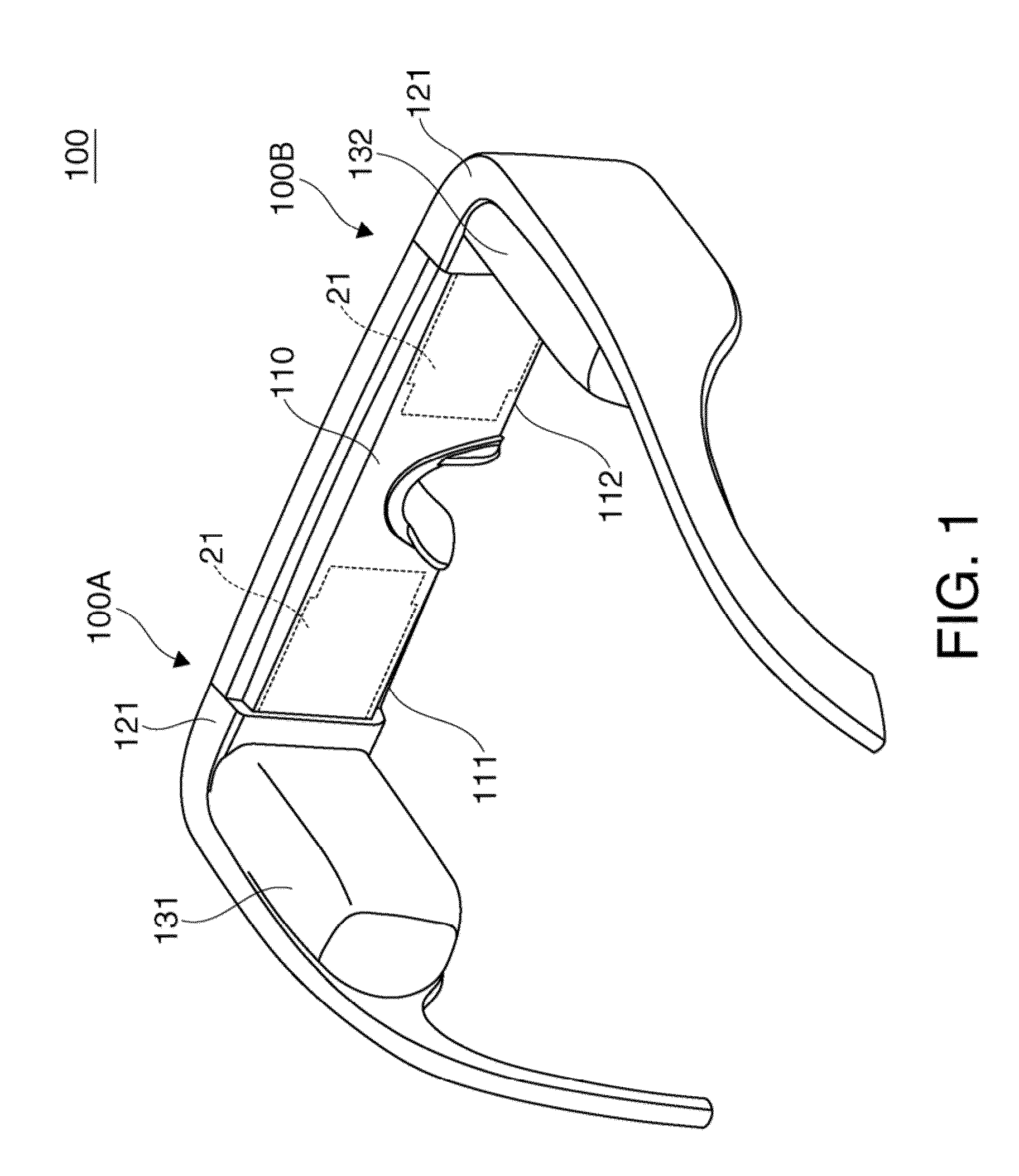

A. Appearance of Virtual Image Display Device

[0039]A virtual image display device 100 of the embodiment shown in FIG. 1 is a head-mounted display having an appearance of eyeglasses, and enables an observer wearing the virtual image display device 100 to recognize image light by a virtual image and observe an external image in a see-through manner. The virtual image display device 100 includes an optical panel 110 that covers the view of observer, a frame 121 that supports the optical panel 110, first and second drive parts 131, 132 added to parts from an end piece to a temple of the frame 121. Here, the optical panel 110 has a first panel part 111 and a second panel part 112, and the panel parts 111, 112 are integrally connected at the center to form a plate-like member. A first display unit 100A formed by combining the first pa...

second embodiment

[0082]As below, fabrication steps of a virtual image display device according to the second embodiment using FIGS. 7A to 7F will be explained, and thereby, the virtual image display device of the embodiment will be explained. Note that the virtual image display device 200 of the embodiment is a modified example of the virtual image display device 100 of the first embodiment and the parts or items without particular explanation are the same as those of the first embodiment, and illustration and explanation will be omitted for others than the structure of a light guiding unit 220 forming the virtual image display device 200. FIG. 1A is a sectional view showing the structure of the light guiding unit 220 manufactured through the respective steps, and FIGS. 7B to 7F show the respective steps for fabrication of the structure in FIG. 7A.

[0083]First, as shown in FIG. 7B, the light guide main body part 20a to be a light guide member 221 is prepared. As shown in FIG. 7C, a hard coating layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acute angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com