Tape printer and recording medium configured to reduce print object size when specified size is impossible to print

a technology of printing machine and printing medium, which is applied in the direction of typewriters, digital output to print units, instruments, etc., can solve the problems of insufficient inability to print, and difficult to form print objects with that size on the print-receiving tape, so as to achieve the effect of reliably forming print objects spanning multiple lines and relatively narrow width of print-receiving tap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The following describes an embodiment of the present disclosure with reference to accompanying drawings.

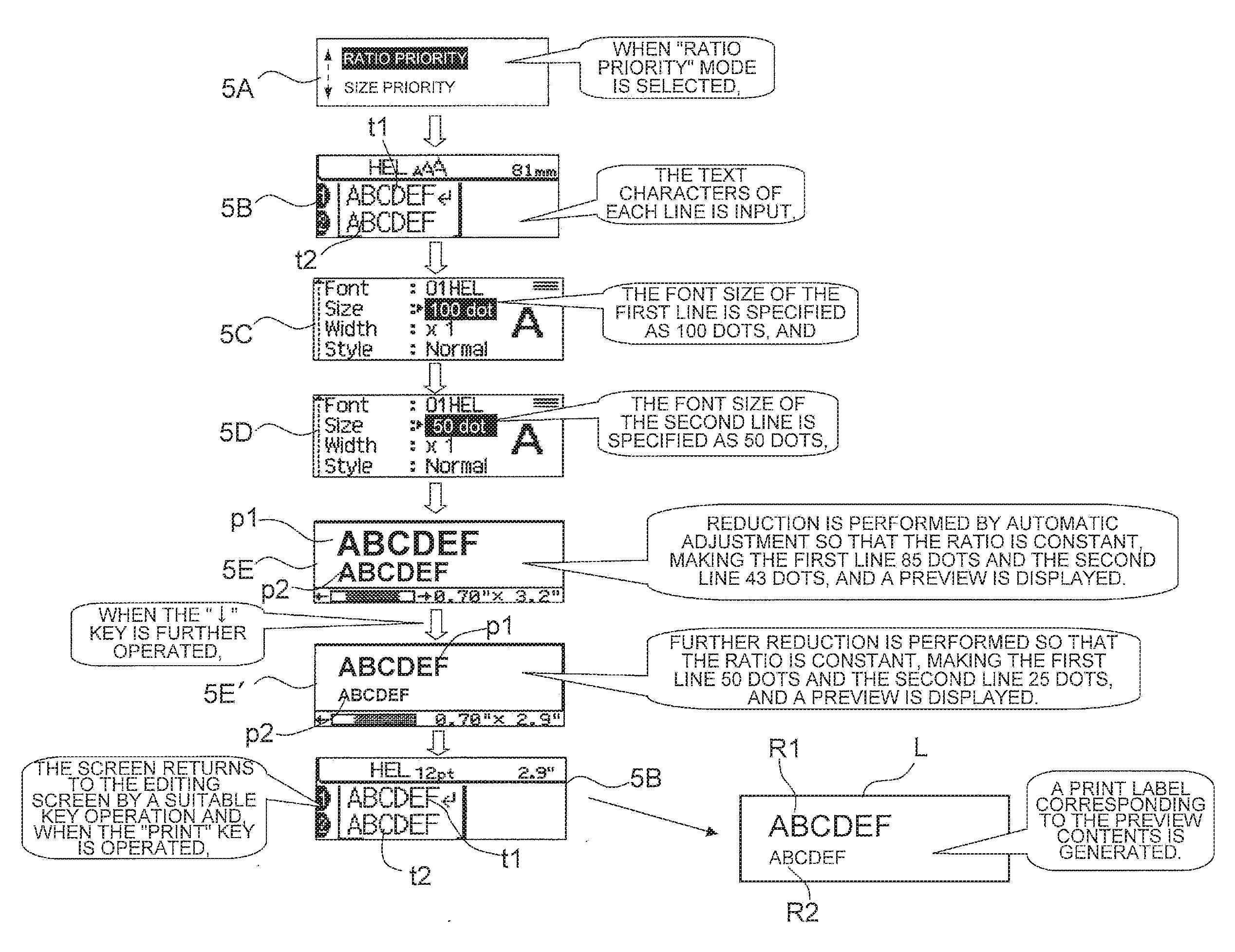

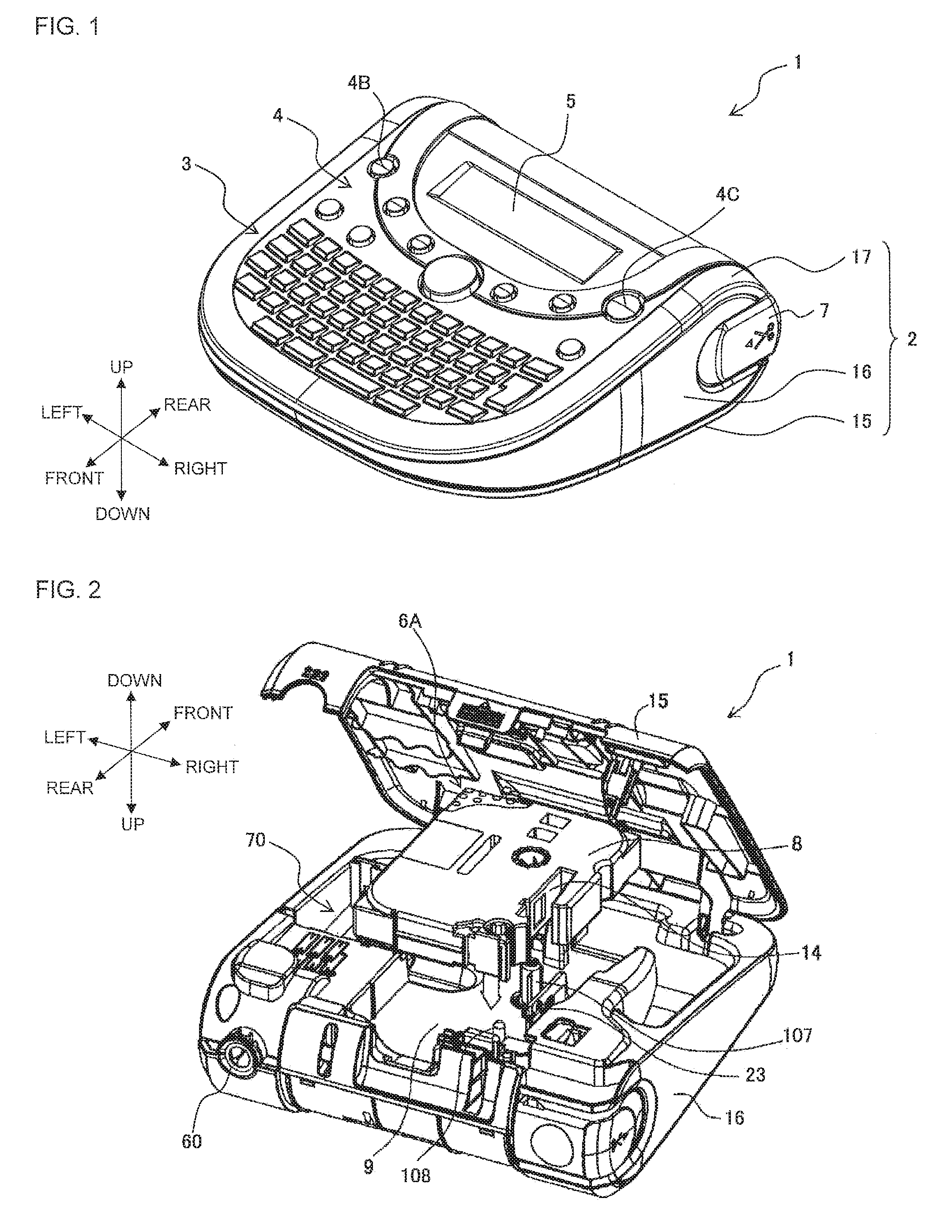

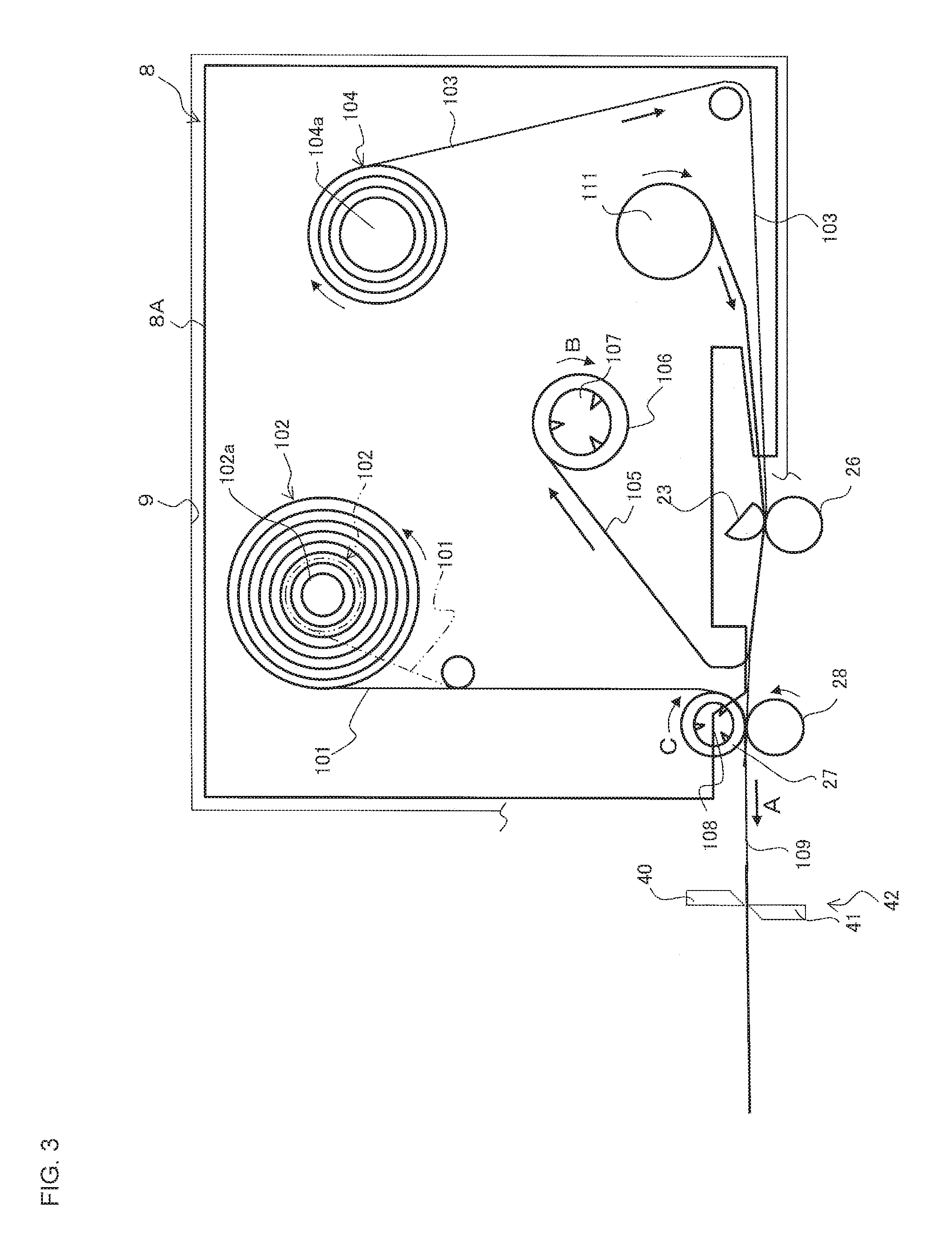

[0017]The general configuration of the tape printer in this embodiment will be described using FIGS. 1-3. In FIG. 1, a tape printer 1 produces a print label L (refer to FIG. 5, FIG. 6, and the like described later) by cutting a label tape with print on which desired printing was performed at a predetermined length. Note that the terms front, rear, left, right, up, and down of the tape printer 1 in this embodiment indicate the directions shown in FIG. 1, FIG. 2, and the like.

General Overall Configuration

[0018]As shown in FIG. 1 and FIG. 2, a housing 2 of the tape printer 1 includes a lower cover 15 constituting the device lower surface, a side cover 16 constituting the device side surface, and an upper cover 17 constituting the device upper surface. A keyboard 3 by which various operations, such as character input and the like, are performed, a function key group 4 for execut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com