Elevator having a rope monitoring arrangement and method for controlling the elevator

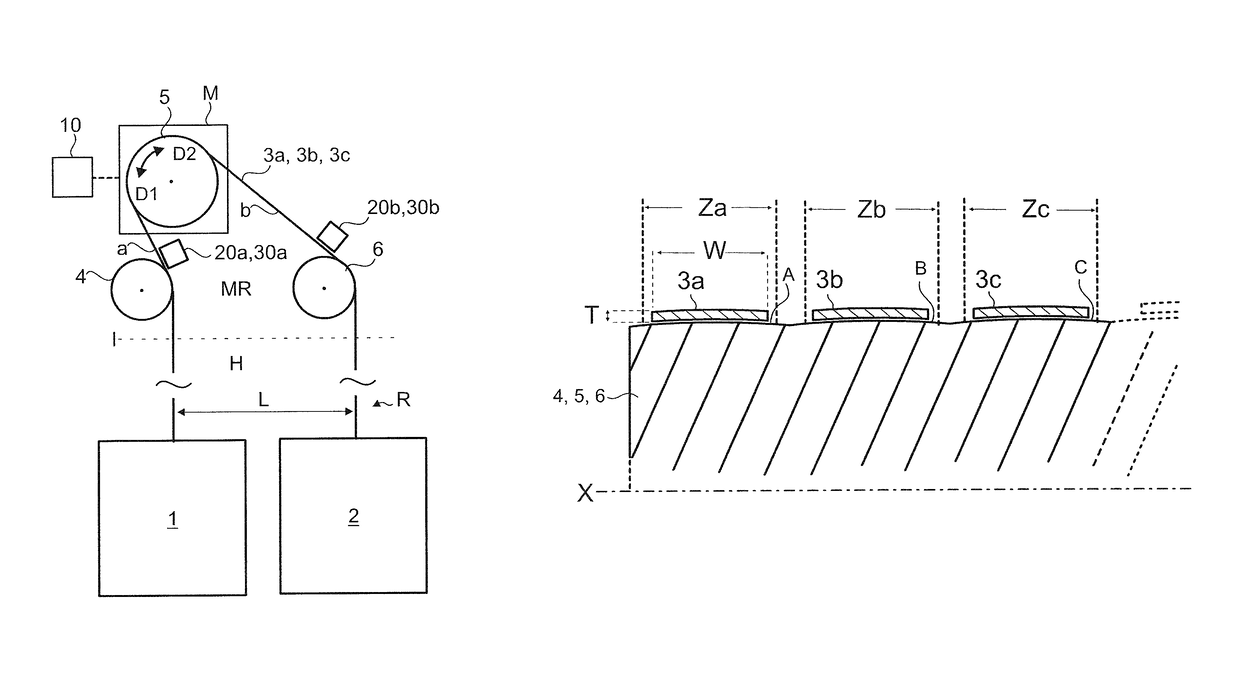

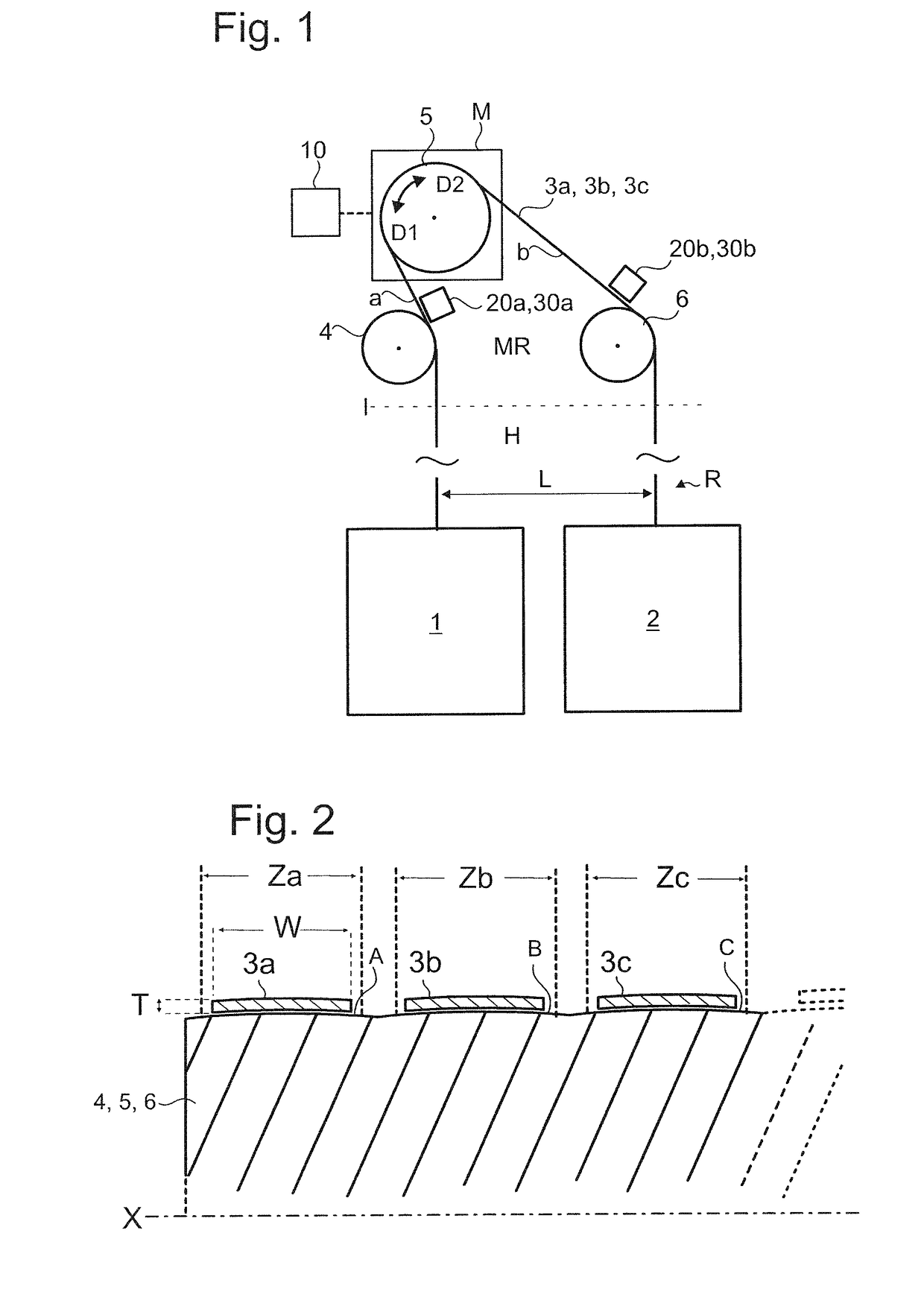

a technology of monitoring arrangement and control method, which is applied in the field of elevators, can solve the problems of insufficient reliability or inability to prevent the further insufficient reliability of mechanical shape locking between the drive wheel and the rope engaging the drive wheel, etc., and achieves rapid and effective response, preventing the development of the problem into even more hazardous state, and facilitating the safety and reliability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

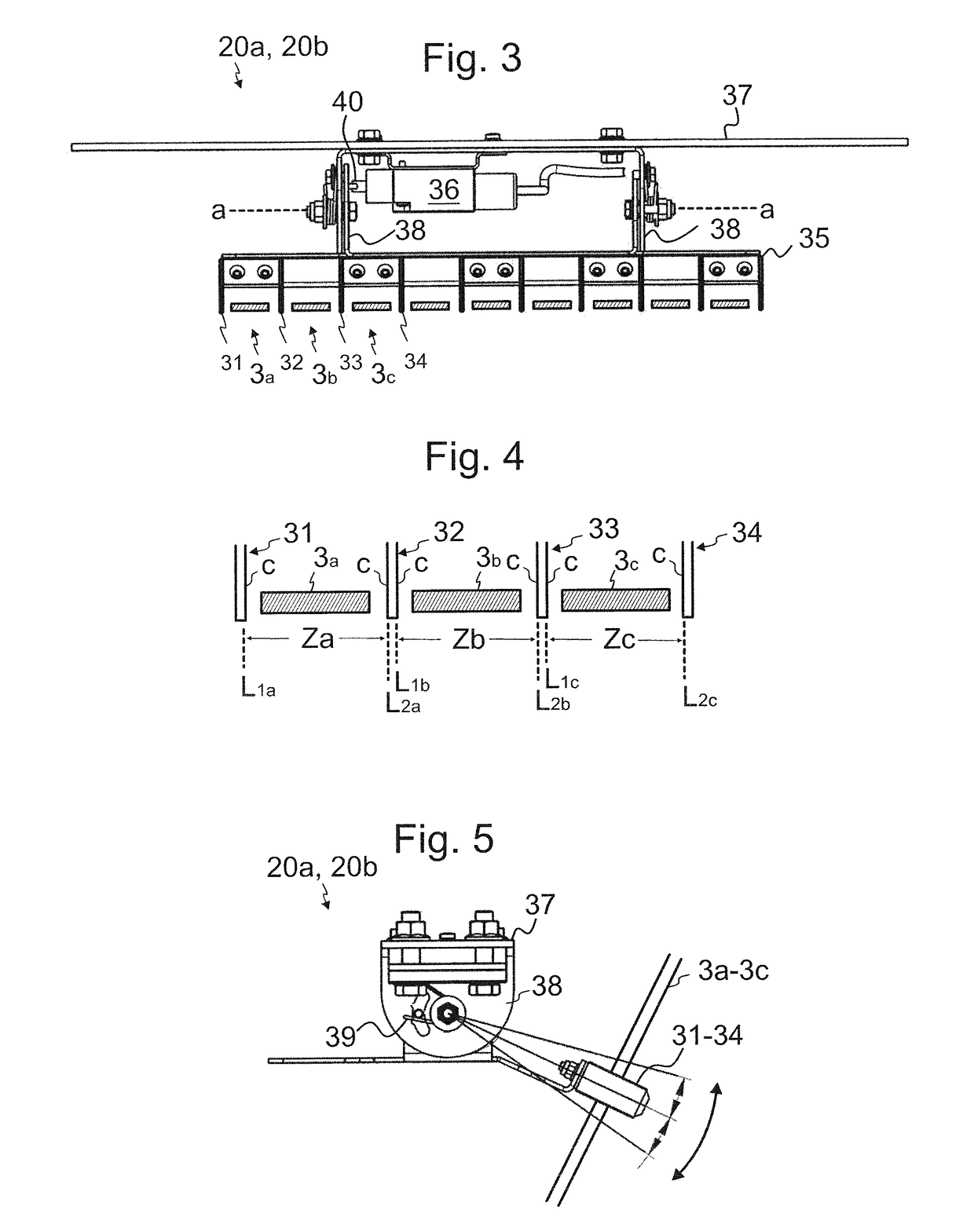

[0097]FIG. 3 illustrates a preferred first embodiment for the detector 20a,20b. The detector 20a,20b comprises for each rope on opposite sides of the rope 3a,3b,3c in said axial direction of the wheels 4,5,6 a first and a second sensing member 31,32; 32, 33; 33,34. In the embodiment as illustrated, there are several ropes whereby there are sensing members which extend between the ropes next to each other. Each sensing member comprises a contact face c which the rope next to it can contact when the rope in question is displaced in said axial direction. Each first sensing member 31,32,33 is positioned at the first limit position L1a,L1b,L1c of the rope in question, such that a contact face c thereof is positioned at the point of the limit position L1a,L1b,L1c. Each second sensing member 32,33,34 is positioned correspondingly at the second limit position L2a,L2b,L2c of the rope in question such that a contact face c thereof is positioned at the point of the limit position L2a,L2b,L2c, ...

second embodiment

[0102]FIG. 6 illustrates a second embodiment for the detector 30a,30b. The detector 30a,30b comprises sensing devices 52-55 for receiving electromagnetic radiation or ultrasonic sound from said limit positions L1a,L2a,L1b,L2b;L1c,L2c and a monitoring unit 51, connected to the sensing devices and arranged to trigger said stopping of the drive wheel 5 if electromagnetic radiation or ultrasonic sound received from one or more of said limit positions L1a,L2a;L1b,L2b,L1c,L2c meet(s) predetermined criteria, such as reaches a predetermined limit or changes in a predetermined way. Each sensing device 52-55 may be in the form of a photocell, infrared, microwave or laser beam sensor, ultrasonic sound sensor for instance. Said sensing devices 52-55 each comprise a receiver for receiving electromagnetic radiation or ultrasonic sound from a limit position L1a,L2a;L1b,L2b,L1c,L2c it is associated with. FIG. 7 illustrates a preferred structure for a sensing device of 52,53,54,55. Preferably, in ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com