Method and apparatus for controlling the strip temperature of the rapid cooling section of a continuous annealing line

a technology of rapid cooling and continuous annealing, which is applied in the direction of heat treatment equipment, instruments, furniture, etc., can solve the problems of inability to control the widthwise temperature of the strip, and achieve the effects of excellent effect, excellent effect, and flatness defects in the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

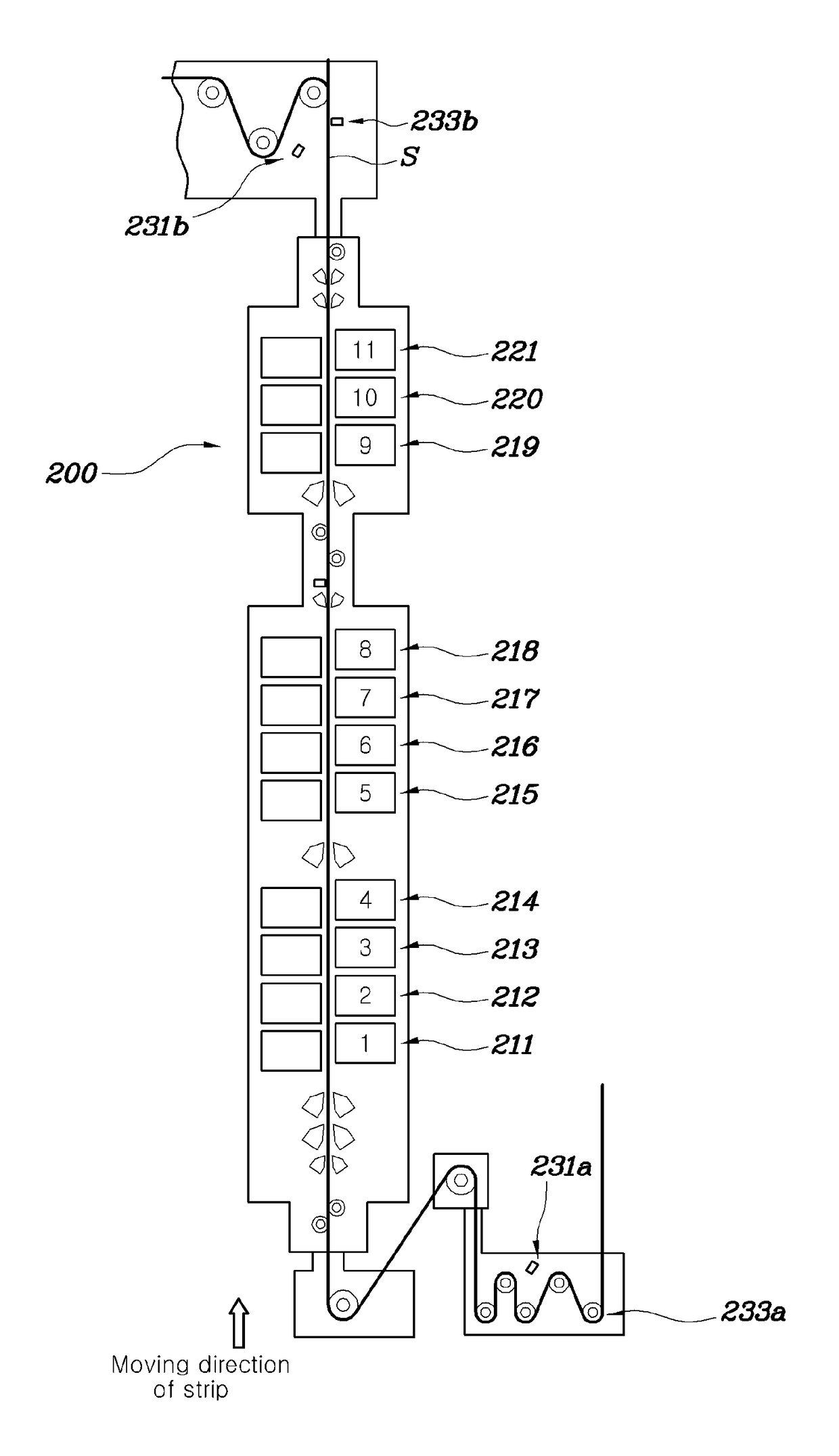

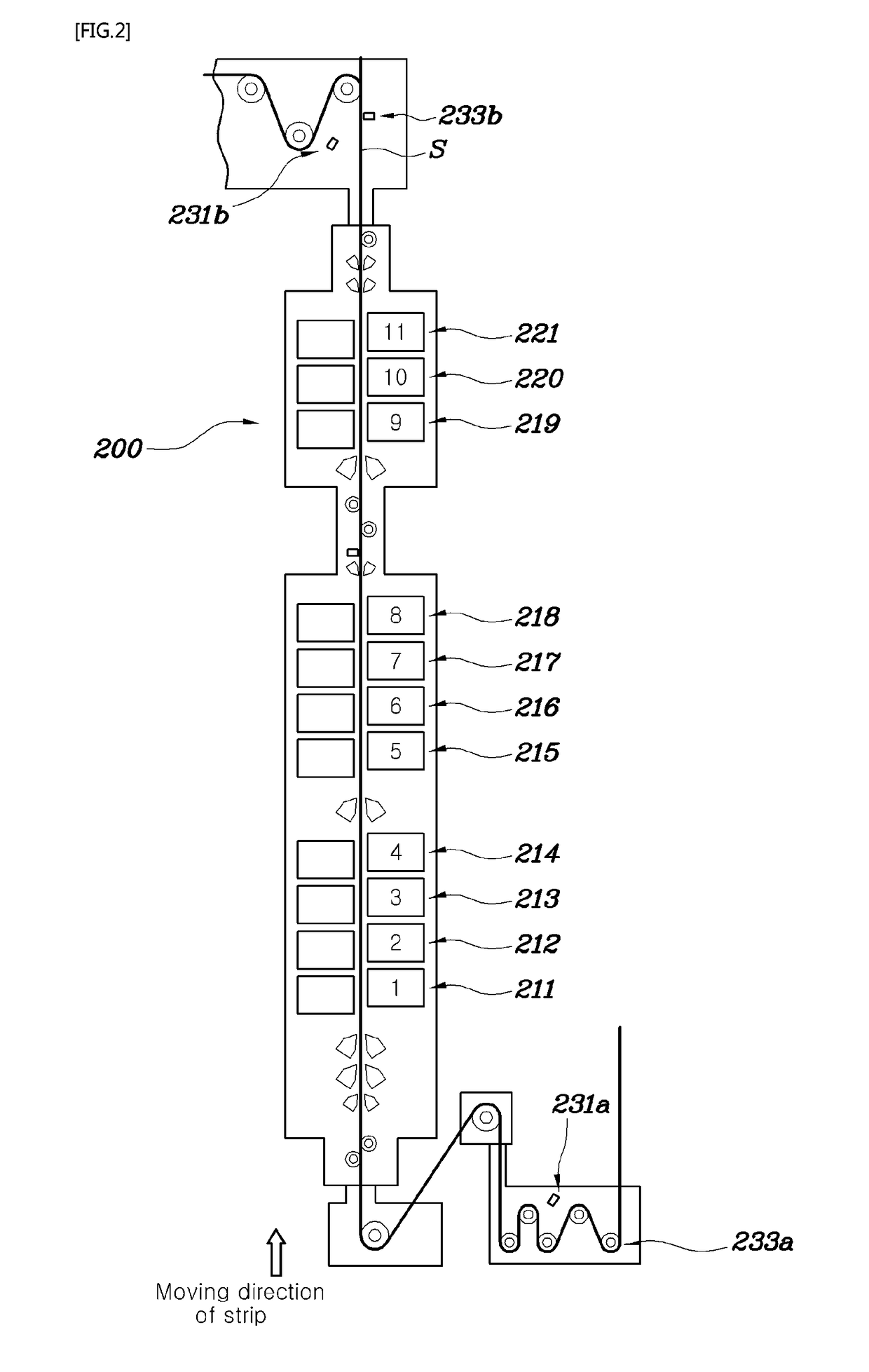

[0030]Hereinafter exemplary embodiments of the present invention will be described in greater detail with reference to the accompanying drawings.

[0031]A method and apparatus for uniformly controlling a strip temperature in a rapid cooling section of a continuous annealing line according to the present invention can measure temperatures using thermometers in an intake end and a discharge end of the rapid cooling section of the continuous annealing line and perform uniform cooling control over the temperature of the strip through flow rate control over spray mist based on feedback / feedforward control technique, thereby minimizing changes in the flatness of the strip.

[0032]First, a description will be given below of an apparatus 100 for uniformly controlling a strip temperature in a rapid cooling section of a continuous annealing line according to the present invention with reference to the drawings.

[0033]the apparatus for uniformly controlling a strip temperature in a rapid cooling se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| flow rates | aaaaa | aaaaa |

| flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com