Molding die, optical element manufacturing method, and optical element

a technology of optical elements and manufacturing methods, applied in the field of molding dies, optical element manufacturing methods, optical elements, etc., can solve the problems of difficult machining, difficult to ensure the space in which the ejector pin is provided, and difficult to ensure the reproducibility of molding while the product portion is pushed out, so as to prevent the concentration of stress on the connecting and prevent the bending or rupture of the gate portion at the time of mold releasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

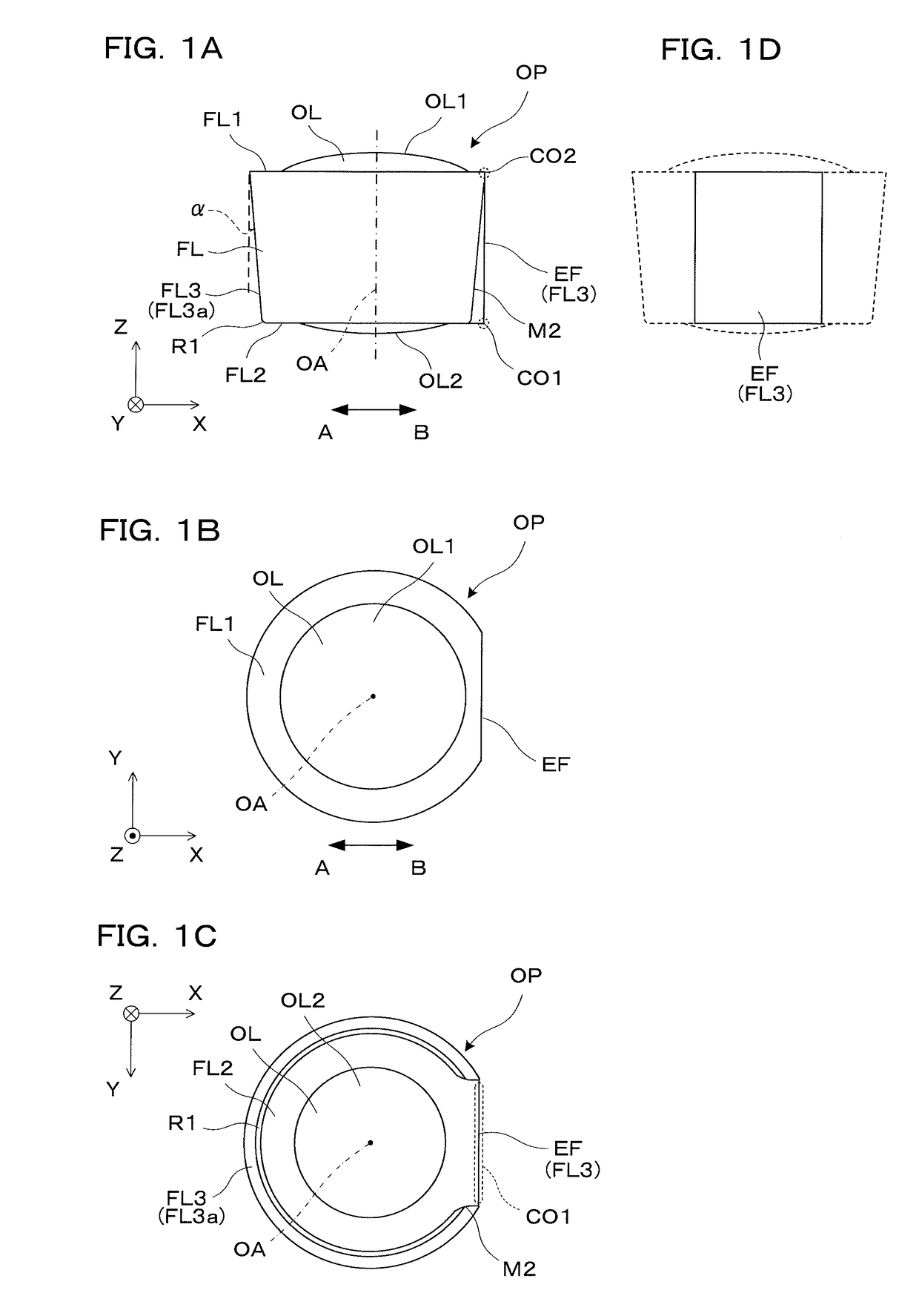

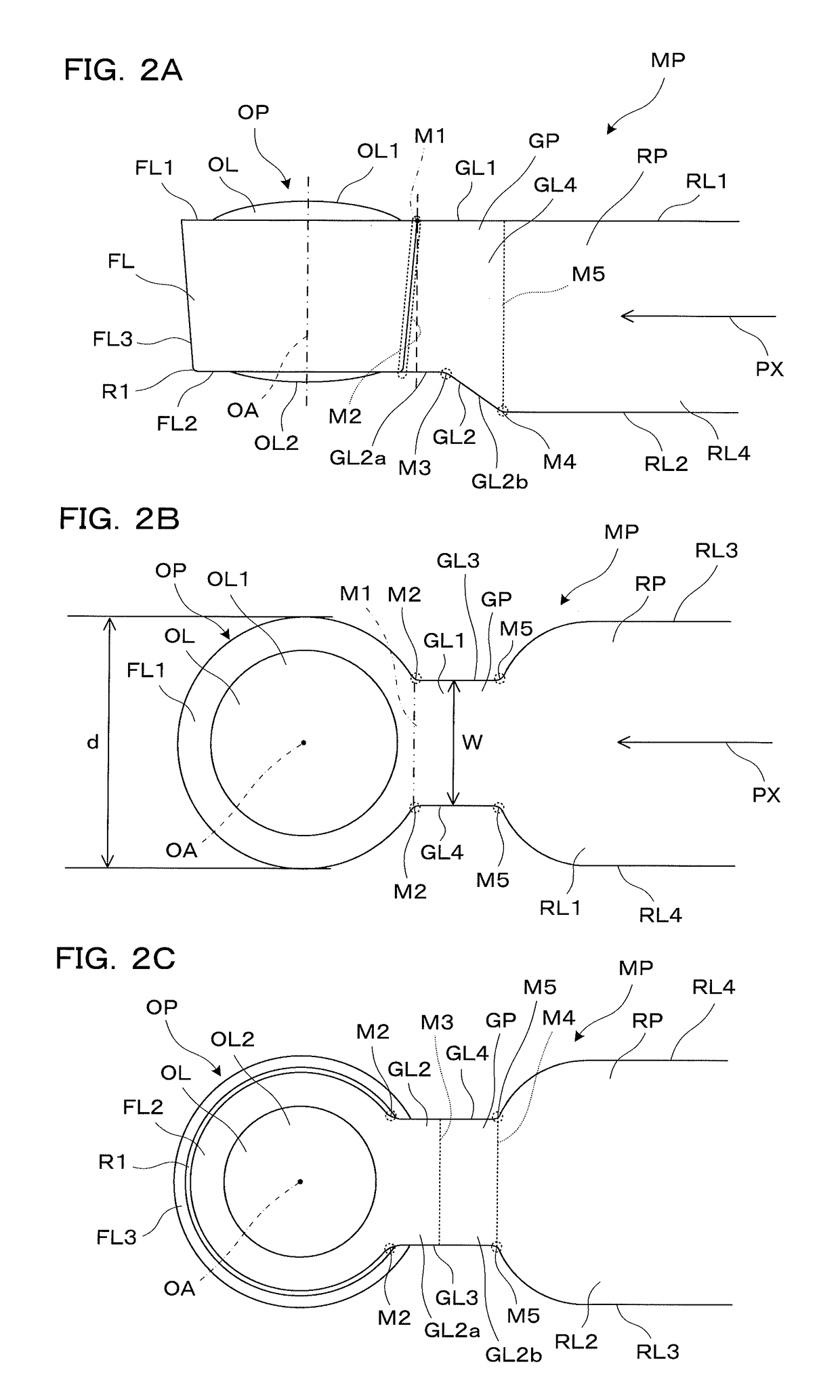

[0041]An optical element of a first embodiment according to the present invention will be described by referring to FIGS. 1A to 1D. A lens OP which is an optical element is a small-sized lens made of a resin and is used as, for example, an objective lens of an optical pickup device (specifically, a lens exclusively used for BD (Blu-ray Disc: trademark)) or a lens for an endoscope. The lens OP is obtained by cutting a gate portion GP in a molding product MP shown in FIGS. 2A to 2C.

[0042]The lens OP has an optical portion OL having an optical function and an annular outer circumferential portion FL extending from the optical portion OL to an outer diameter direction. In the lens OP, the optical portion OL has a convex first optical surface OL1 and a convex second optical surface OL2. Namely, the optical portion OL is thicker on a center side. The first optical surface OL1 and the second optical surface OL2 are generally smooth and face each other by sandwiching a body (center of the l...

second embodiment

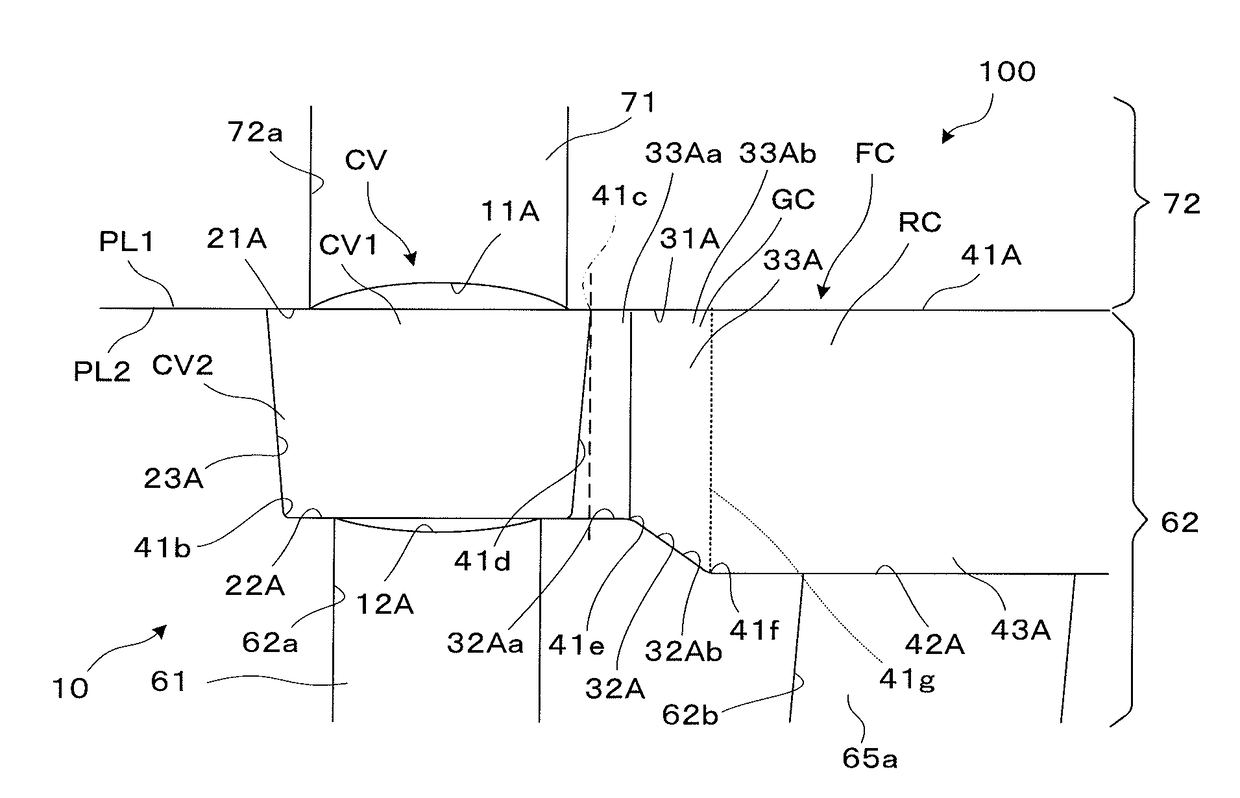

[0066]Hereinafter, a molding die and the like of a second embodiment will be described. The molding die and the like of the second embodiment are a modification of the molding die and the like of the first embodiment, and the matters not particularly described are similar to those in the first embodiment.

[0067]As shown in FIGS. 6A and 6B, in the movable die 10, the second gate-forming surface 32A of the gate-forming portion GC has the first transfer surface 32Aa extending outward from the second outer circumferential transfer surface 22A and parallel to the mold mating surface PL1, and the second transfer surface 32Ab extending outward from the first transfer surface 32Aa and inclined to the first transfer surface 32Aa. Furthermore, the gate side surface-forming surfaces 33A and 34A of the gate-forming portion GC have third transfer surfaces 33Aa and 34Aa extending outward from the side-surface transfer surface 23A and perpendicular to the portion 41c connecting the mold mating surf...

third embodiment

[0069]Hereinafter, a molding die and the like of a third embodiment will be described. The molding die and the like of the third embodiment are a modification of the molding die and the like of the first embodiment, and the matters not particularly described are similar to those in the first embodiment.

[0070]As shown in FIGS. 7A and 7B, in the movable die 10, the second gate-forming surface 32A of the gate-forming portion GC has a gentle curved surface from the second outer circumferential transfer surface 22A side to the second runner-forming surface 42A side. Namely, in the movable die 10, the gate-forming portion GC has its depth increasing as going from the outer circumference-forming portion CV2 side toward the runner-forming portion RC side.

[0071]As shown in FIG. 7C, the molding product MP molded by the molding die 100 shown in FIGS. 7A and 7B has the second gate surface GL2 formed as a gentle curved surface with the thickness increasing as going from the outer circumferential...

PUM

| Property | Measurement | Unit |

|---|---|---|

| taper angle | aaaaa | aaaaa |

| R-shape | aaaaa | aaaaa |

| taper angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap