Axially compact direct drive for storage disk hub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

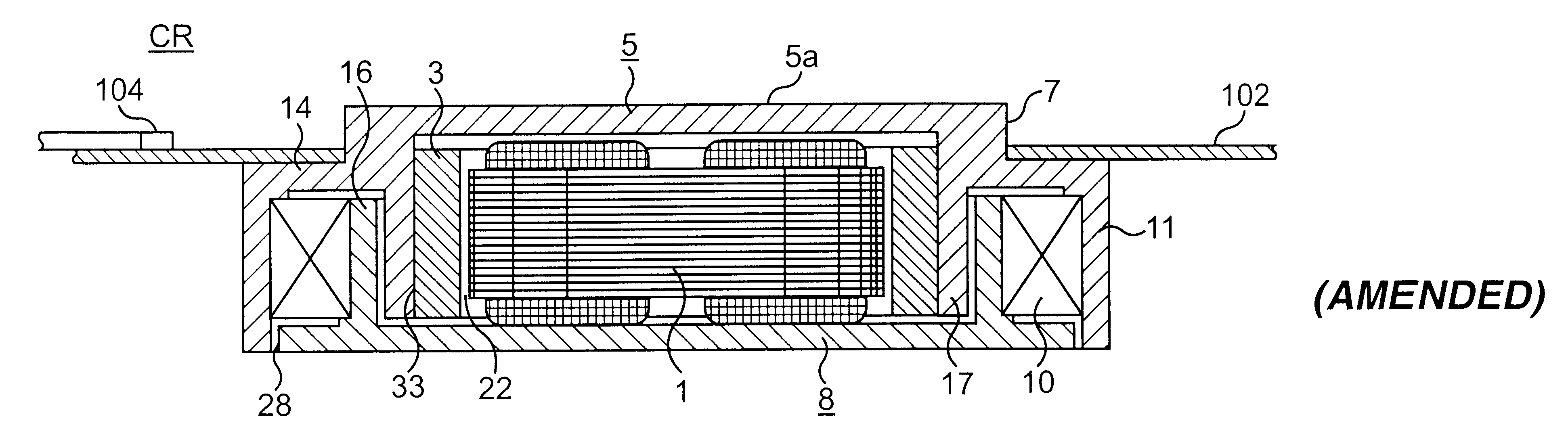

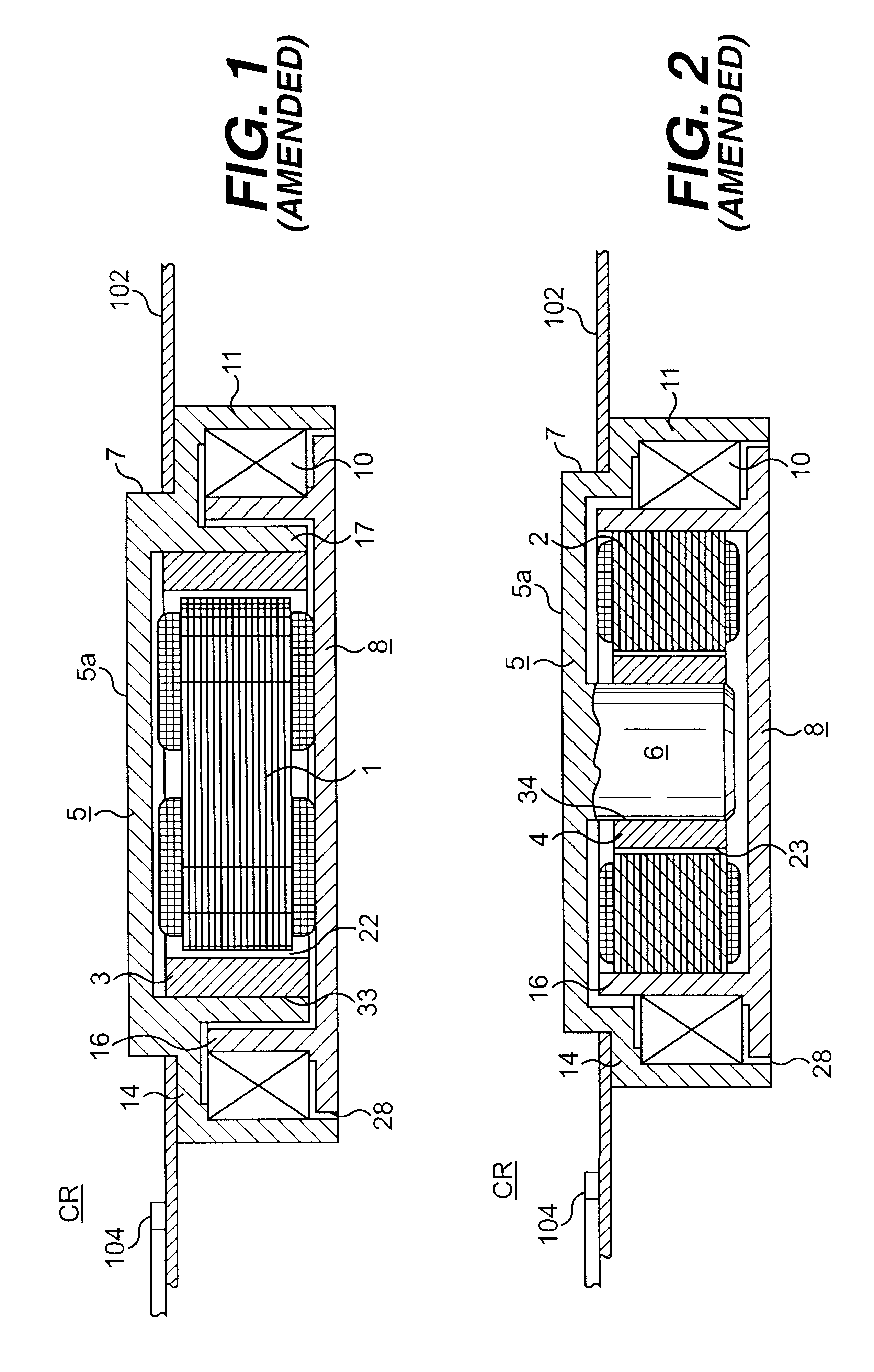

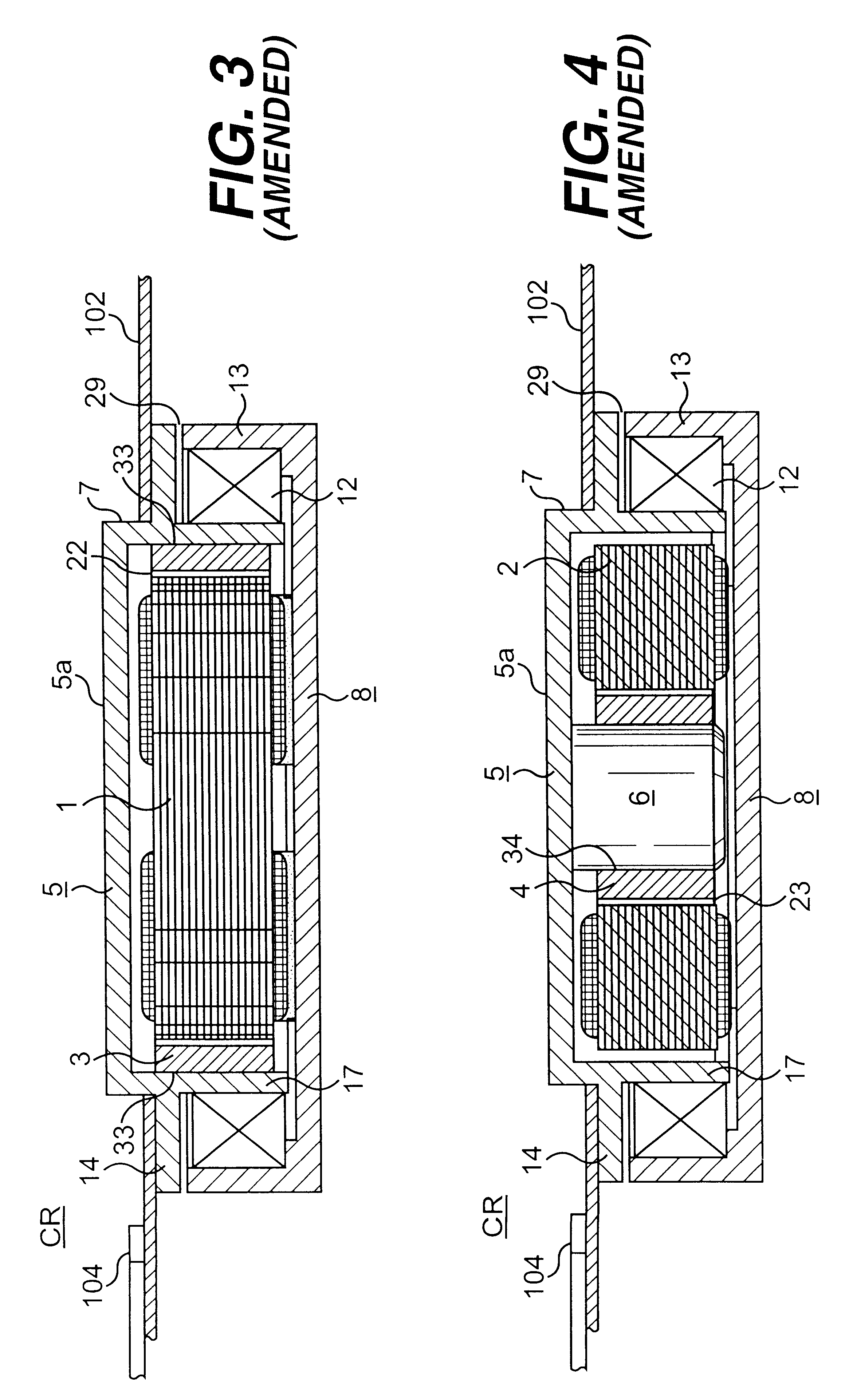

FIGS. 1, 3 and 5 show what are referred to as external rotor variants, in which therefore an internal stator 1 with a cylindrical external circumference is rigidly fixed to a base plate 8, and a permanent magnetic ring 3 is rotatable about the cylindrical external circumference of the internal stator 1. The magnetic ring, with or without a separate hollow cylindrical magnetic return ring 11, forms the electromotive drive element in the external rotor, which is in the shape of a cup or a bell and into which this permanent magnetic rings is inserted.

FIGS. 2, 4 and 6 show as an alternative what are referred to as internal rotor solutions, in which a rotor shaft 6 directly carries a permanent magnetic rotor ring (if necessary, also with the interposition of a soft magnetic, hollow cylindrical return ring), the external circumference of which rotates in the interior of a hollow annular stator iron core which is in turn rigidly connected to a base plate 8.

The rotor may advantageously comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com