Metal shingle with gutter and interlocking edges

a technology of metal shingles and gutters, applied in the field of roof shingles, can solve the problems of water migrating around the edges of metal shingles, or smooth surface, shingle,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

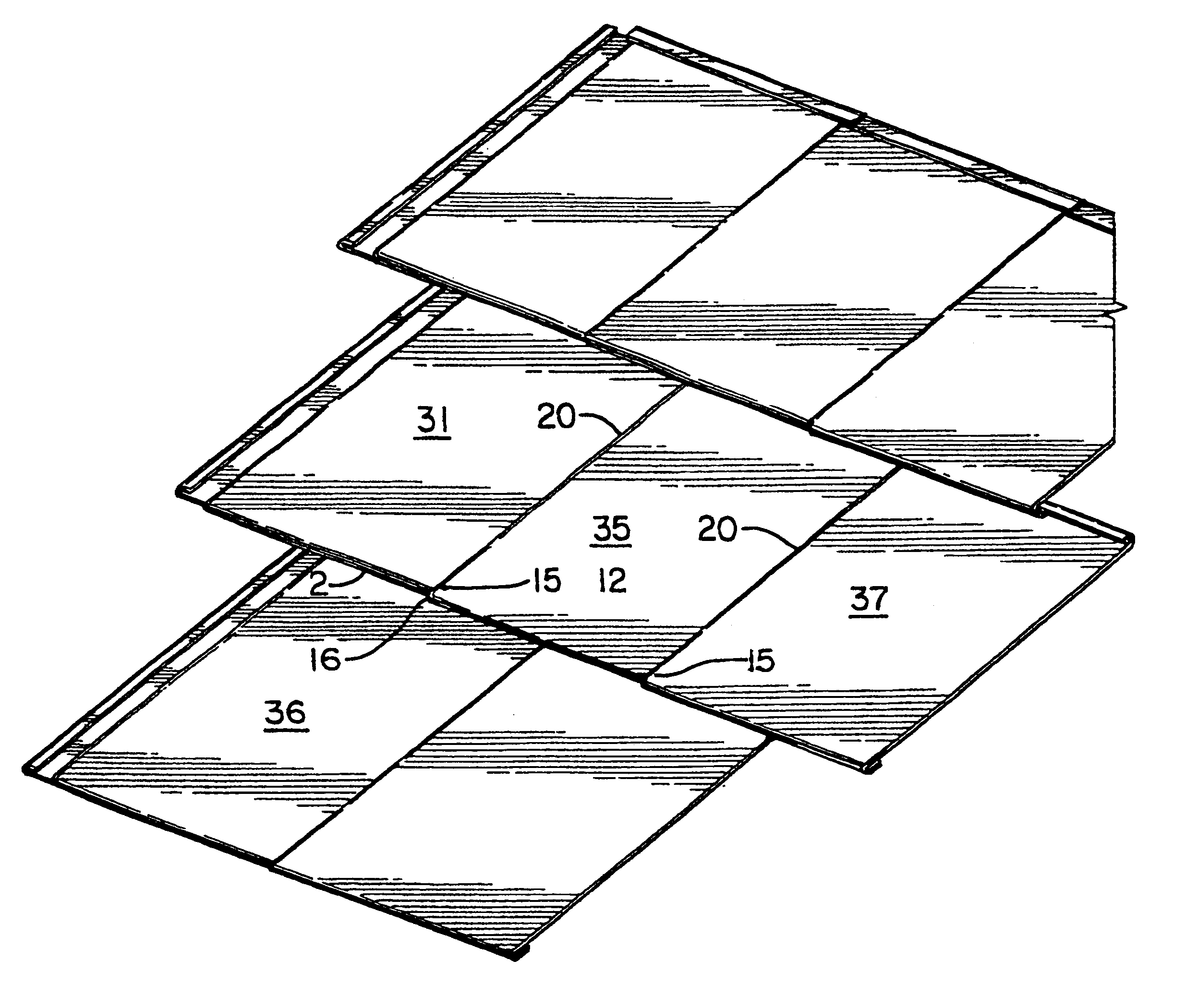

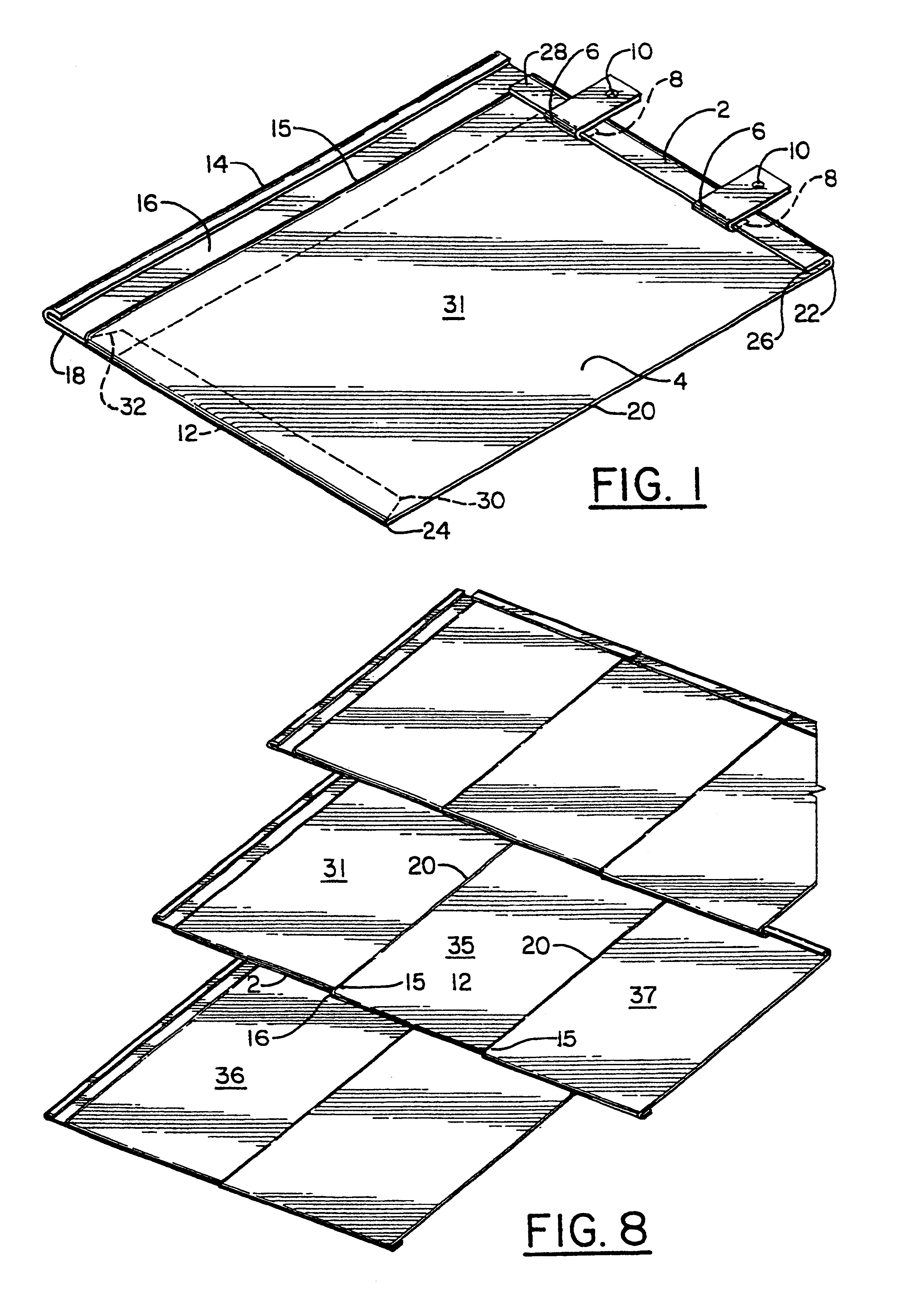

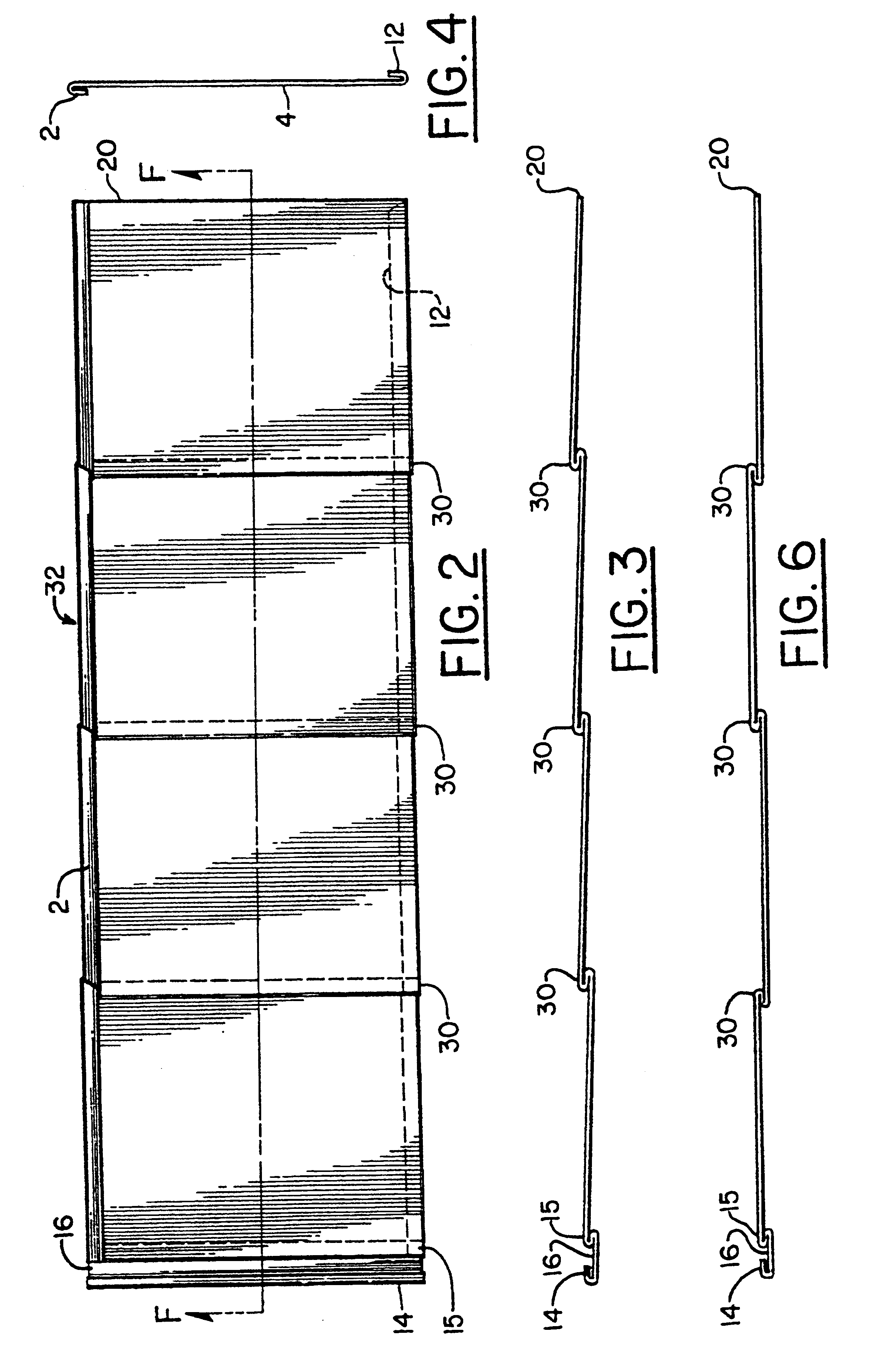

FIG. 1 shows a top view of a preferred embodiment of the shingle 31. Upper edge 2 is folded-over to the top plan surface 4 to allow engagement with mounting bracket 6, or with the lower edge 12 of the next higher shingle. Mounting bracket 6 has a folded-under lower edge 8 and a hole 10. The bracket lower edge 8 is hooked onto the shingle upper edge 2 and nailed to the roof (not shown) through hole 10 to hold the shingle 31 in place on the roof (not shown).

The shingle lower edge 12 is folded under for engagement with the upper edge fold 2 of the next lower shingle. The left side, or trailing, edge 14 is folded-over toward the top surface of the shingle 31. The shingle top surface has an S fold 15 spaced inwardly from the trailing edge 14 that divides a gutter surface 16 from the rest of the top surface 4 of the shingle 31. Thus, water flowing to the left side of the shingle 31 over the S fold 15 is caught in a gutter formed by trailing edge 14, gutter surface 16 and S fold 15. The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com