Universal coupler for spinal fixation

a universal coupler and spinal technology, applied in the field of spinal fixation connectors, can solve the problems of complex surgical procedures, designed to accommodate stress much higher, and current bolt-to-rod connectors that do not allow adjustment in multiple planes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

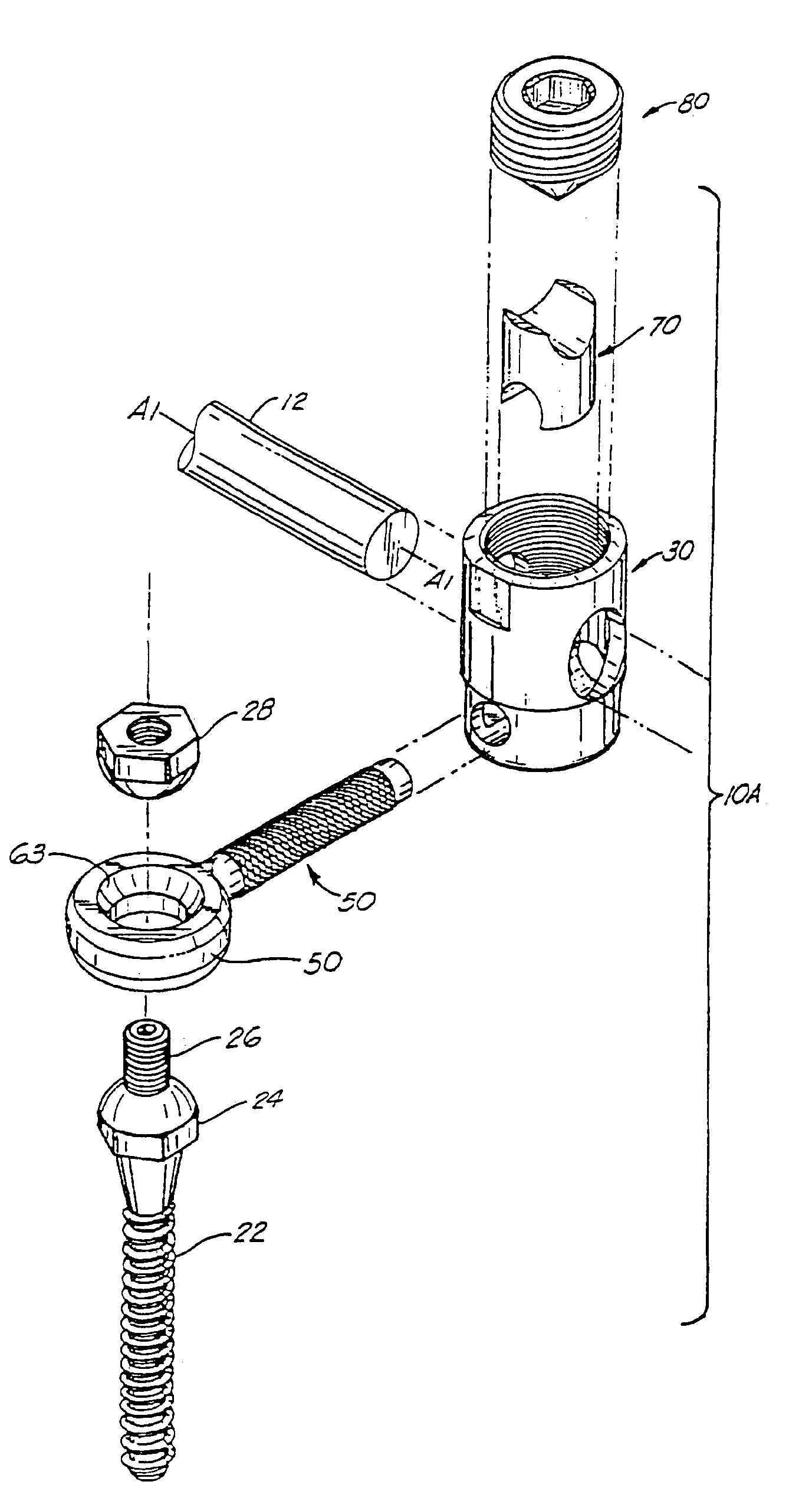

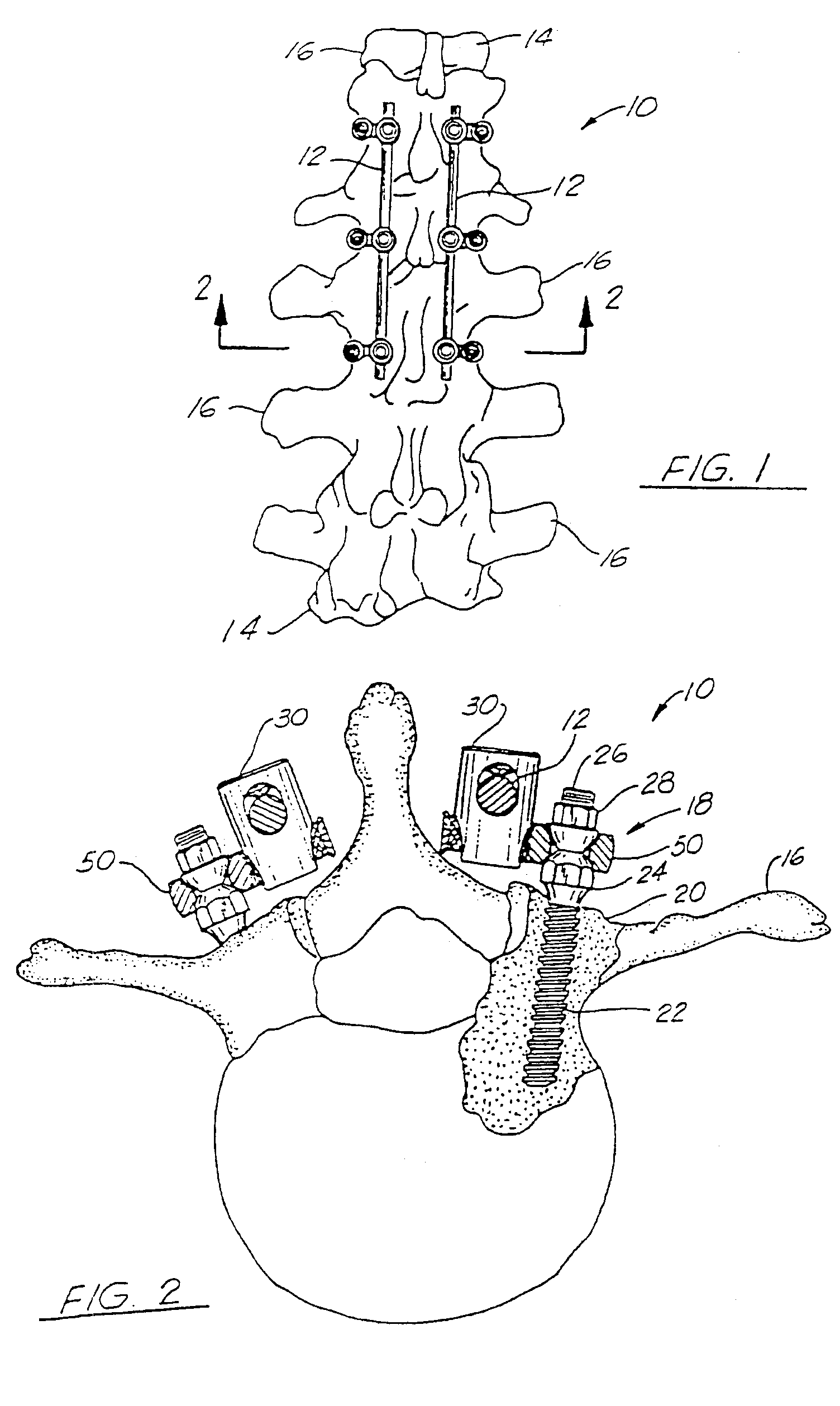

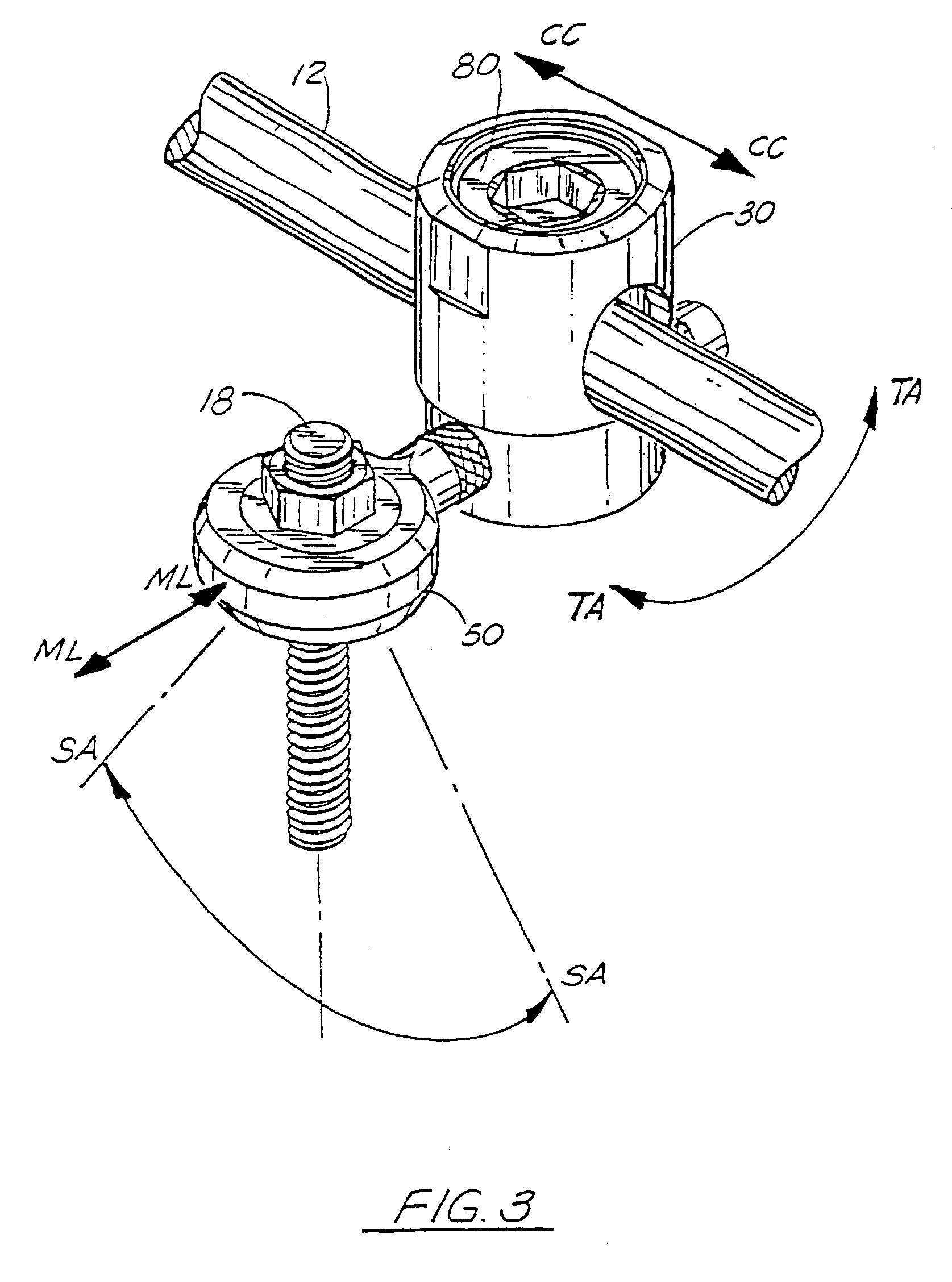

[0034]FIGS. 1 and 2 show the preferred embodiment of the coupler assembly of the present invention, designated generally by the numeral 10 implanted in a spinal column. Coupler assembly 10 includes a coupler body or member 30, an eyebolt member 50, an insert 70 and a set screw 80, and is used to attach longitudinal rods 12 to a vertebral column 14 comprising a plurality of vertebrae 16. The coupler assembly 10 is shown attached to three vertebrae 16 as part of a spinal implant system that is used to hold and stabilize vertebrae 16. Although the attachment of only three vertebrae 16 is shown, it should be understood that the number of assemblies 10 used can vary such that any number of vertebrae can be held in place.

[0035]Each of the assemblies 10 is connected to a respective vertebrae 16 by a fastener 18 which may be either a bone bolt (FIGS. 2, 3, 4) or a bone screw 18A (FIG. 4A). The fastener 18 is shown in FIGS. 2, 3 and 4 as bone bolt 18 having a first threaded end portion 22 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com