Double-lumen catheter

a double-lumen catheter and catheter technology, applied in the field of catheters, can solve the problems of occlusion of the uptake lumen end, failure of the catheter, and many failure modes of the prior art catheter,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

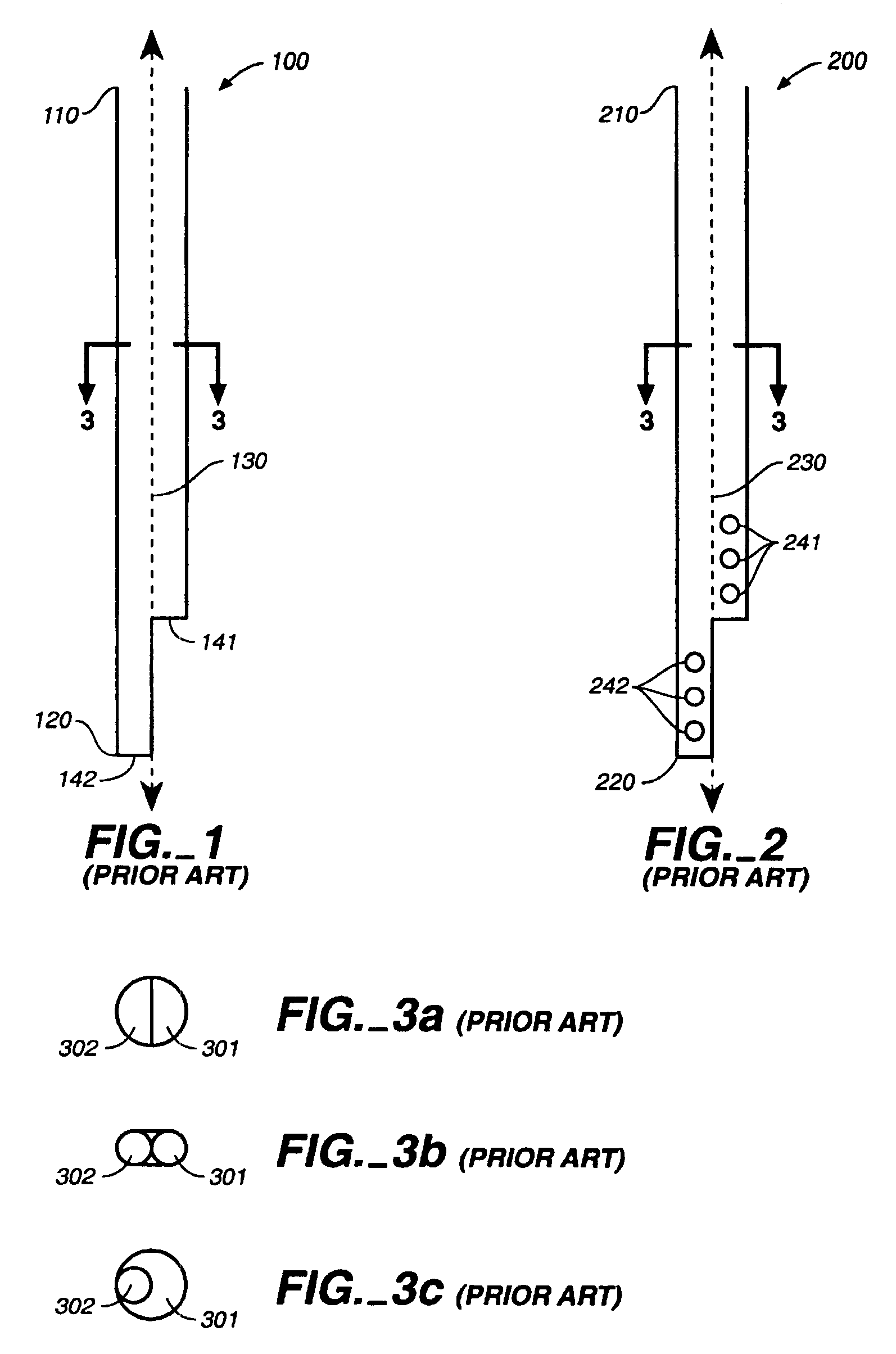

[0025]FIG. 4 is a side view of the catheter of the present invention. Catheter 400, in FIG. 4, has a proximal end 410, a distal end 420, and a central axis 430. Catheter 400 includes a shaft segment 490 (which may also herein be referred to as the intravenous portion) and a distal end segment 450. In one embodiment, distal end segment is 450 is much smaller than the shaft segment 490. (Please note that figures in this application are not drawn to size.) Central axis 430 is a straight line that runs along the length of the catheter 400, including the shaft segment 490 and distal end segment 450.

[0026]Catheter 400 includes an uptake lumen side hole 441 and a return lumen end hole 442 in the distal end segment 450. In catheter 400, uptake lumen side hole 441 is the only uptake lumen hole. Catheter 400 does not have any other uptake lumen side holes in addition to uptake lumen side hole 441. Additionally, catheter 400 does not include an uptake lumen end hole since the distal end of upt...

second embodiment

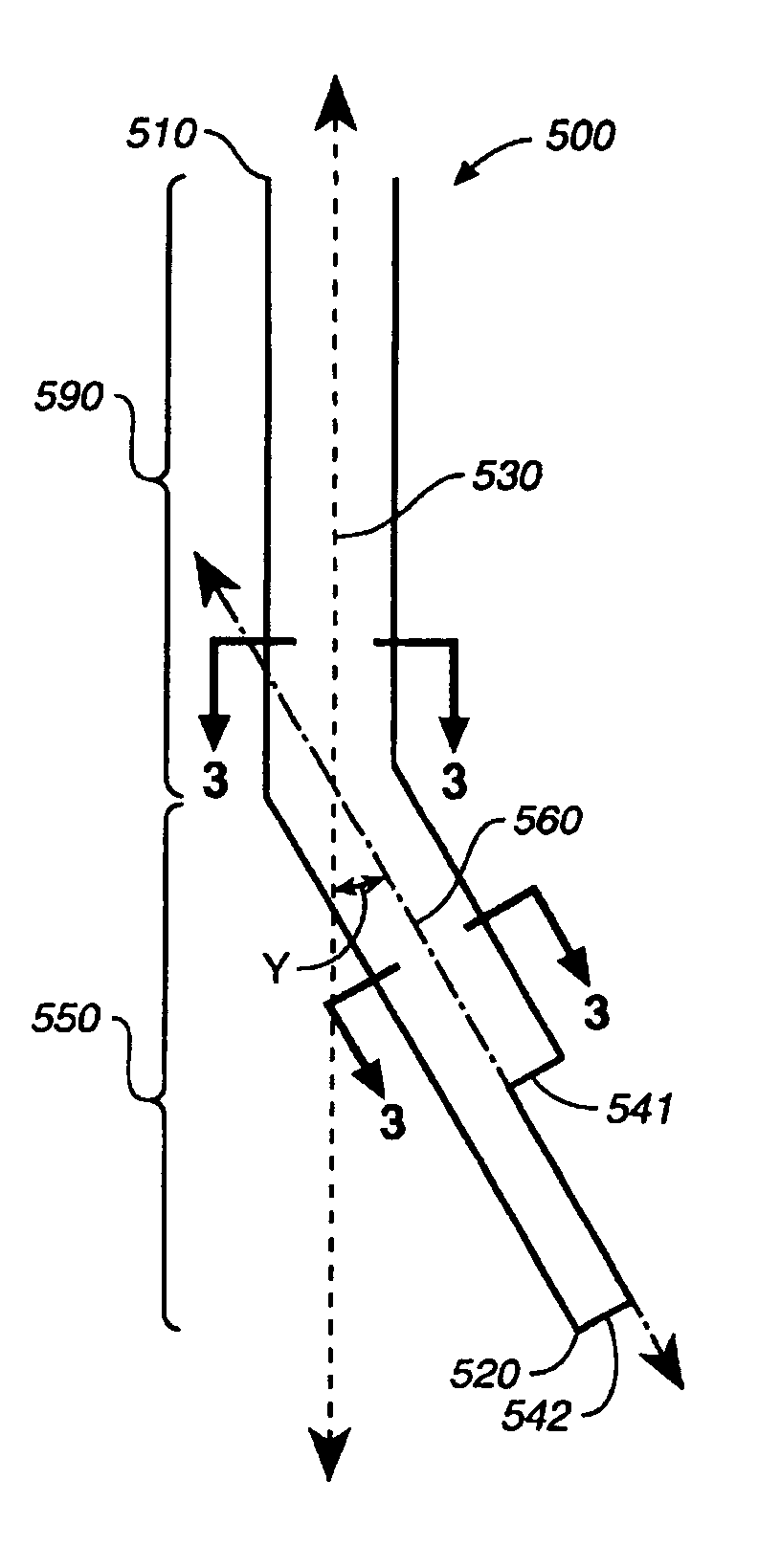

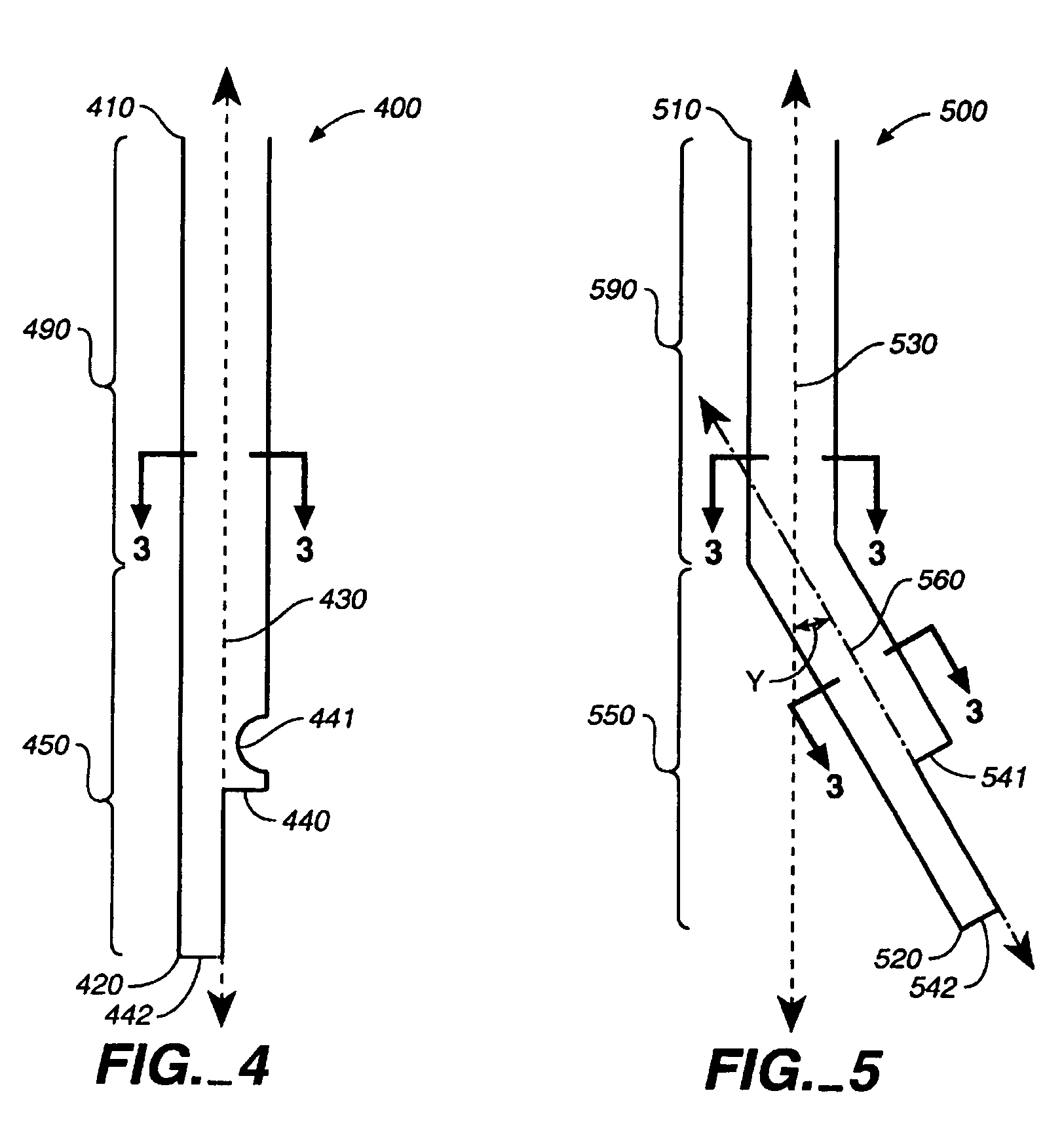

[0030]FIG. 5 is a side view of the catheter of the present invention. Catheter 500 has a proximal end 510, a distal end 520, and a central axis 530. Catheter 500 includes a shaft segment 590 and a distal end segment 550. Central axis 530 runs along the length of shaft segment 590. Distal end segment 550 includes central axis 560 which forms a non-zero angle Y with central axis 530. Thus, the distal end segment 550 is angled away from the central axis 530 of the catheter.

[0031]Angled distal end segment 550 includes both a portion of the uptake lumen and a portion of the return lumen. Three embodiments of the cross sectional view along line 3—3 in the distal end segment 550 are shown in FIGS. 3a, 3b, and 3c.

[0032]Angled distal end segment 550 includes a return lumen end hole 542 and an uptake lumen end hole 541 that is located proximally with respect to the return lumen end hole 542. Angled distal end segment 550 allows the uptake lumen end hole 541 of the uptake lumen of the catheter...

third embodiment

[0034]FIG. 6 is a side view of the catheter of the present invention. In FIG. 6, catheter 600 has a proximal end 610, a distal end 620, and a central axis 630. Catheter 600 includes a shaft segment 690 and a distal end segment 650. Central axis 630 runs along the length of shaft segment 690.

[0035]Distal end segment 650 includes an uptake lumen end segment 651 and a return lumen end segment 652. Uptake lumen end segment 651 and return lumen end segment 652 each comprise separate tubes. Uptake lumen end segment 651 has a central axis 661 that forms a non-zero angle Z with central axis 630. Thus, uptake lumen end segment 651 is angled with respect to the central axis 630. On the other hand, return lumen end segment 652 has a central axis 662 that is parallel to the central axis 630. Thus, return lumen end segment 652 is not angled with respect to the central axis 630. However, there is a non-zero angle Z between central axis 662 of the return lumen end segment 652 and central axis 661 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com