Method for sharpening bedknives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]In the following detailed description, certain specific terminology will be employed for the sake of clarity and a particular embodiment described in accordance with the requirements of 35 USC 112, but it is to be understood that the same is not intended to be limiting and should not be so construed inasmuch as the invention is capable of taking many forms and variations within the scope of the appended claims.

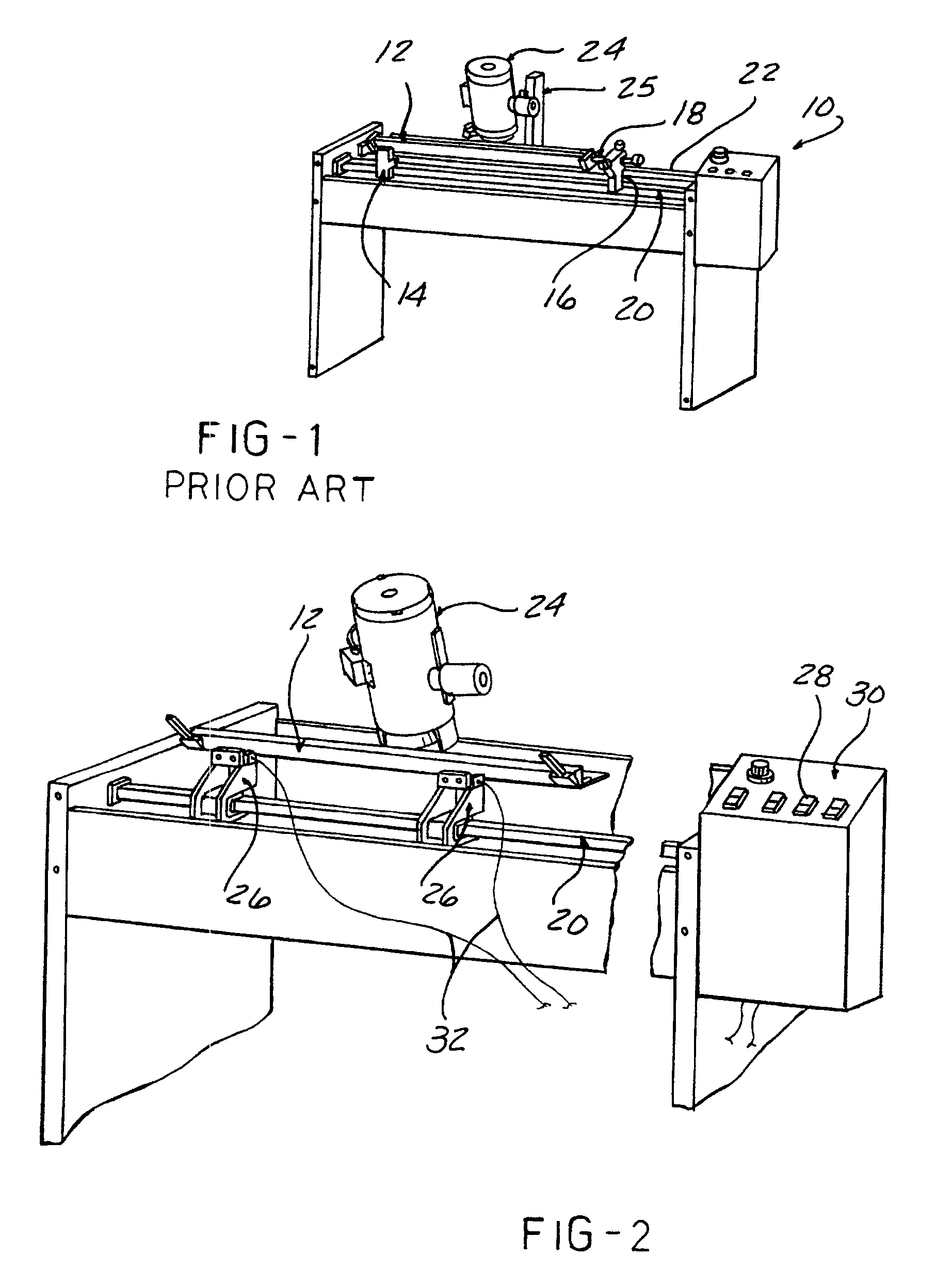

[0021]Referring to FIG. 1, a prior art bedknife grinder 10 is depicted in which a bedknife 12 is mounted between centers 14 and 16 engaging the pivot points 18 on which the bedknife 12 is supported in the mower. The centers 14, 16 are clamped to a support rail 20 extending parallel to ways 22 on which a grinding motor 24 carriage 25 is traversed by means of a power screw (not shown). In order to properly set up the machine for grinding, the bedknife 12 axis is aligned with the carriage ways 22 by means of a gauge and adjustment of the right hand center 16. This requires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com