Window frame for manufactured housing

a technology for manufactured housing and window frame, which is applied in the direction of building components, applications, and closure members, etc., can solve the problems of small misalignment of the end of the window frame, the expansion and contraction of vinyl and aluminum, and the problem of lap siding manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

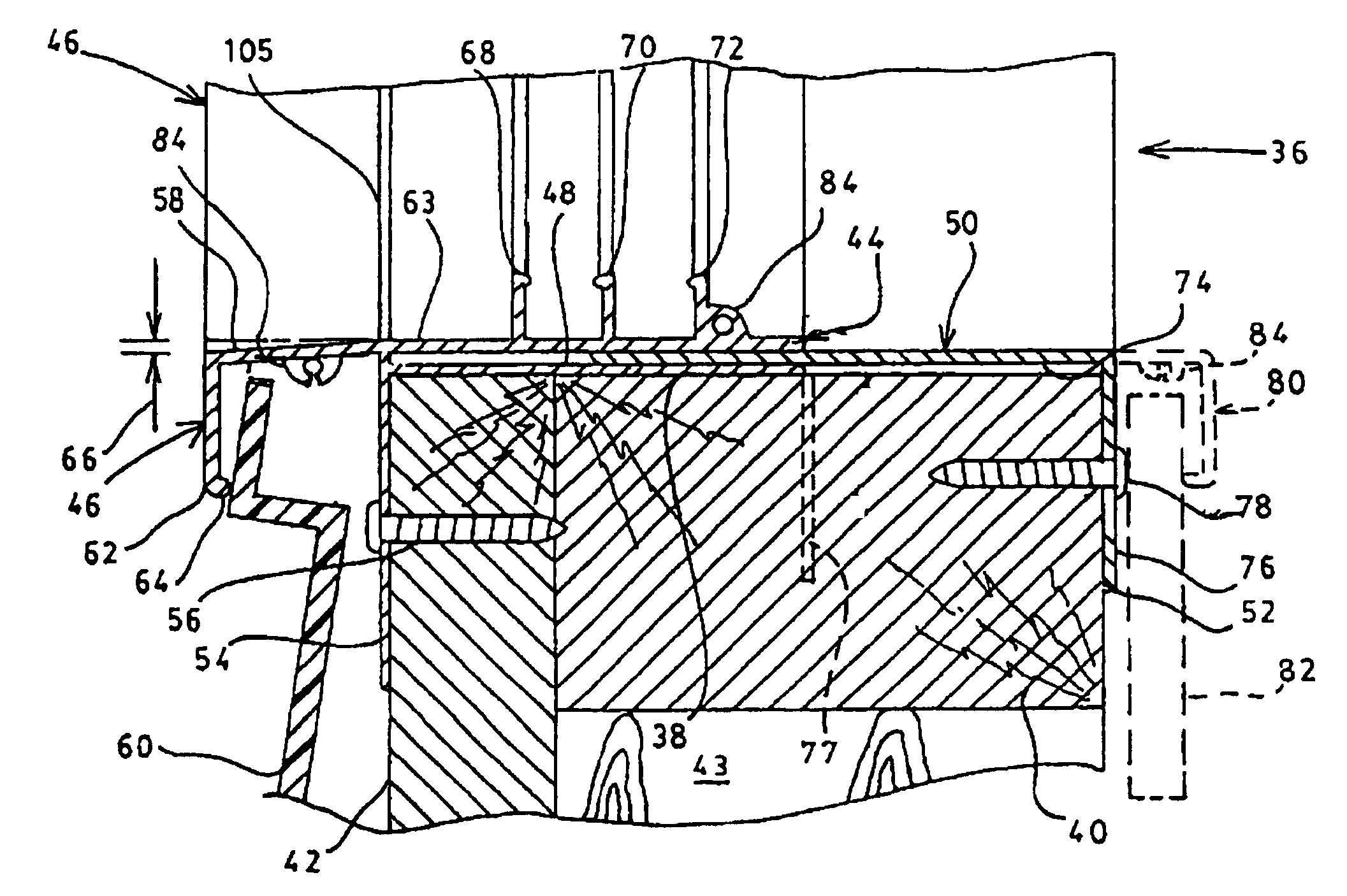

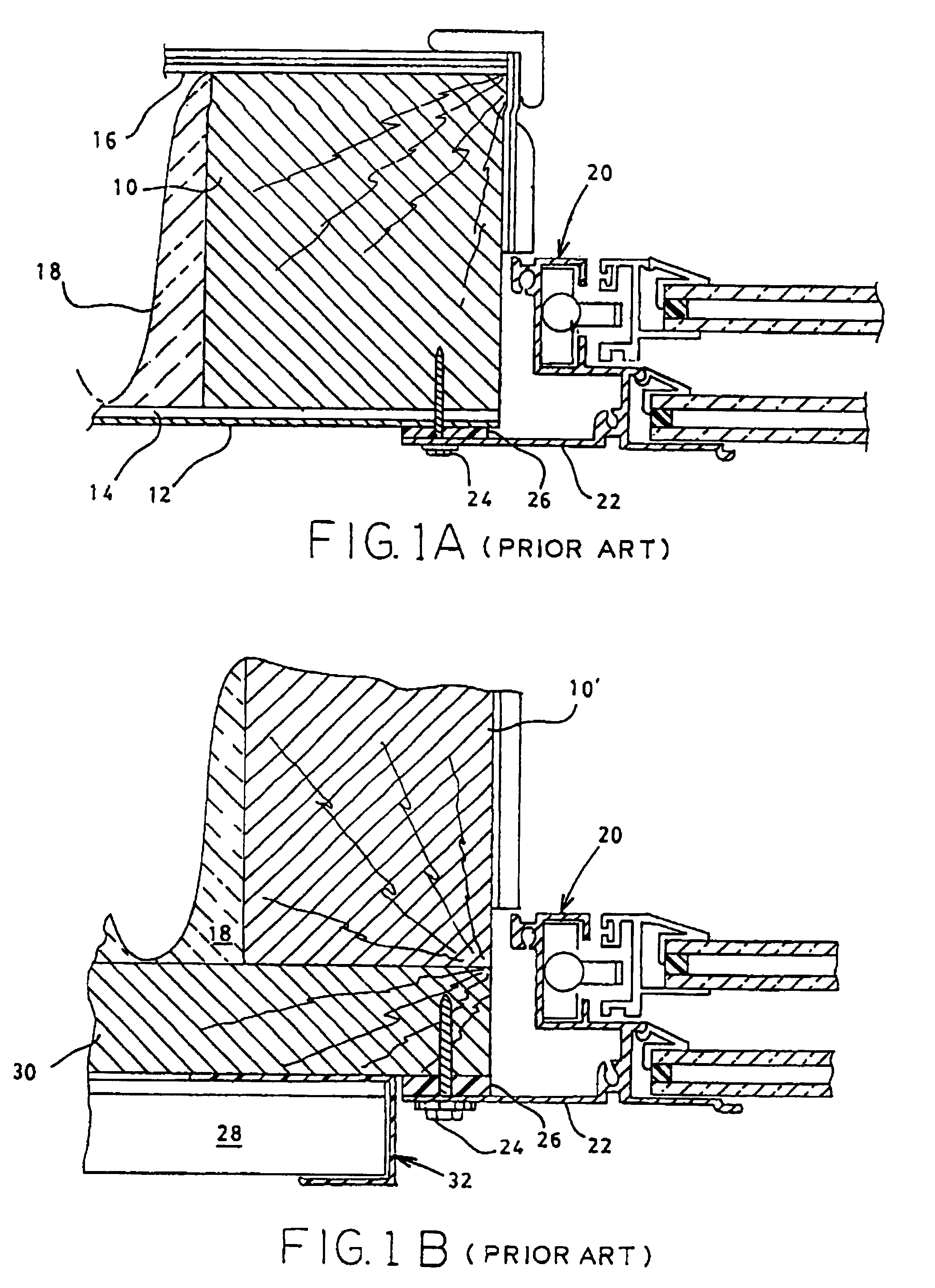

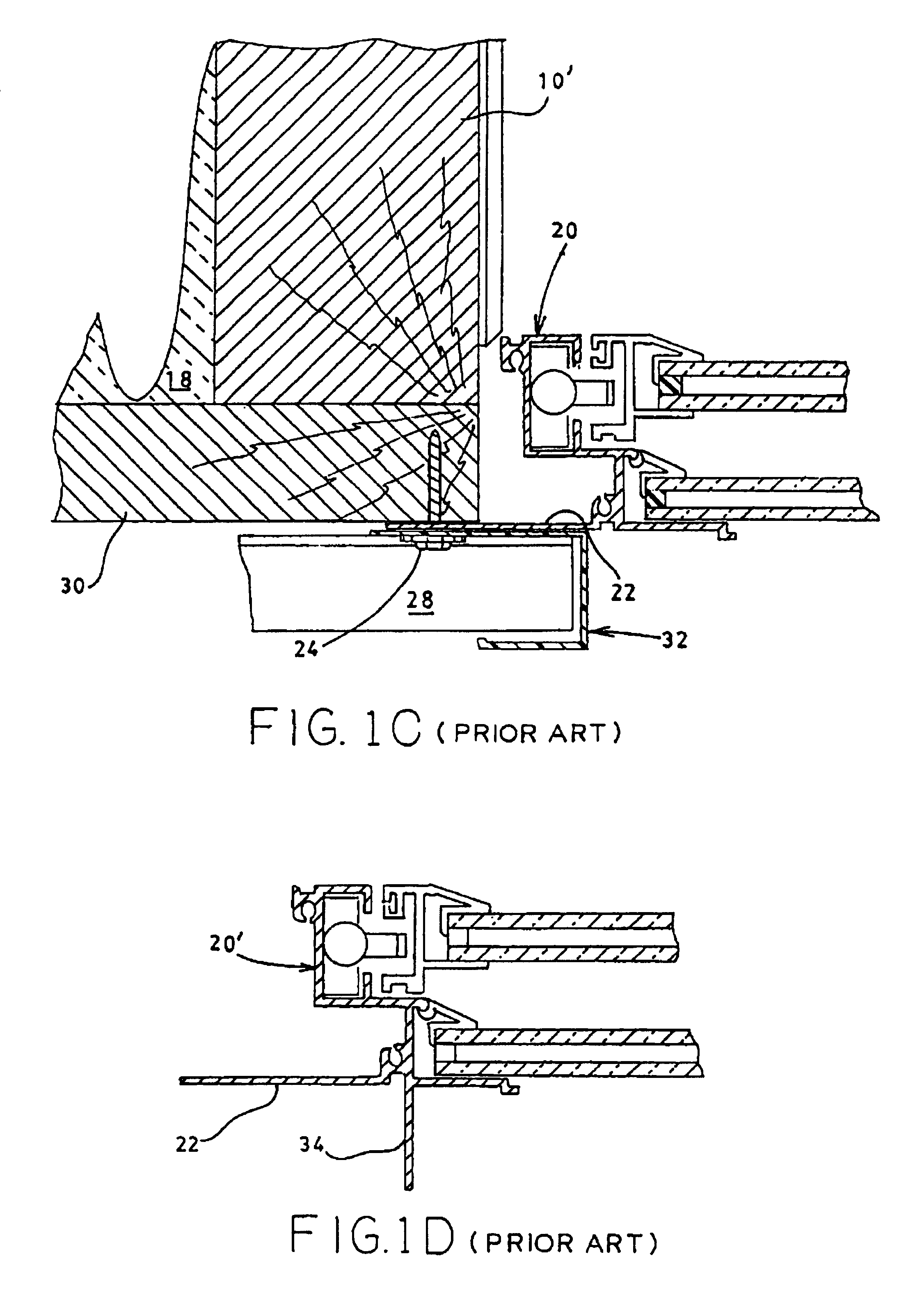

[0021]The departure of the present invention from the prior art of window / siding relationships will be better understood by first considering the construction that had existed prior to the present invention. Therefore, referring to FIG. 1A, shown therein is an early wall / window structure as utilized in manufactured housing. The frame of the housing unit was typically a series of 2 in.×2 in. elements 10 that were covered on the exterior with sheet metal 12 which was, in some embodiments, embossed or corrugated to give some improved visual appearance. There may be, or may not be, a thin sheeting layer 14 The inner surface of this building frame was typically covered with panelling 16, and the void between the layers was filled with insulation 18. At places where windows were desired, an opening was cut through the wall of appropriate size, and a prefabricated window unit 20 was inserted having a perimeter flange 22. Although this FIG. 1A (and FIGS. 1B-1D) illustrate upper and lower do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com