Method and device for measuring stepped driving wheel pair with structural optical sight sensing

A measurement method and measurement device technology, which is applied in the direction of rim measurement/measurement, can solve the problems of not having the diagnosis of wheel tread abrasion and peeling, the reliability and measurement accuracy need to be further improved, and the inability to meet the high-precision requirements, etc., to achieve Improve the real-time performance and work efficiency, improve the measurement accuracy and system reliability, and realize the effect of dynamic online automatic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

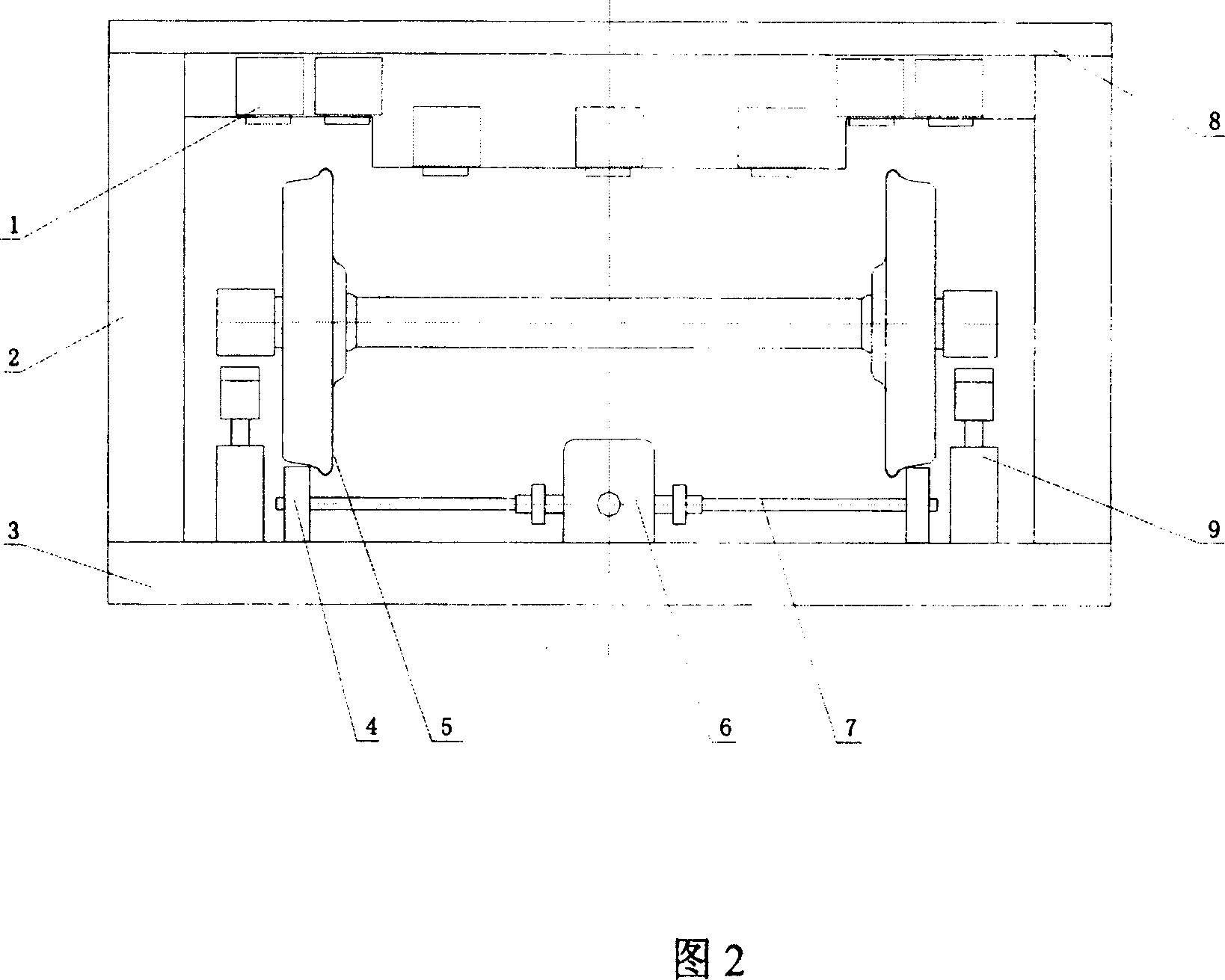

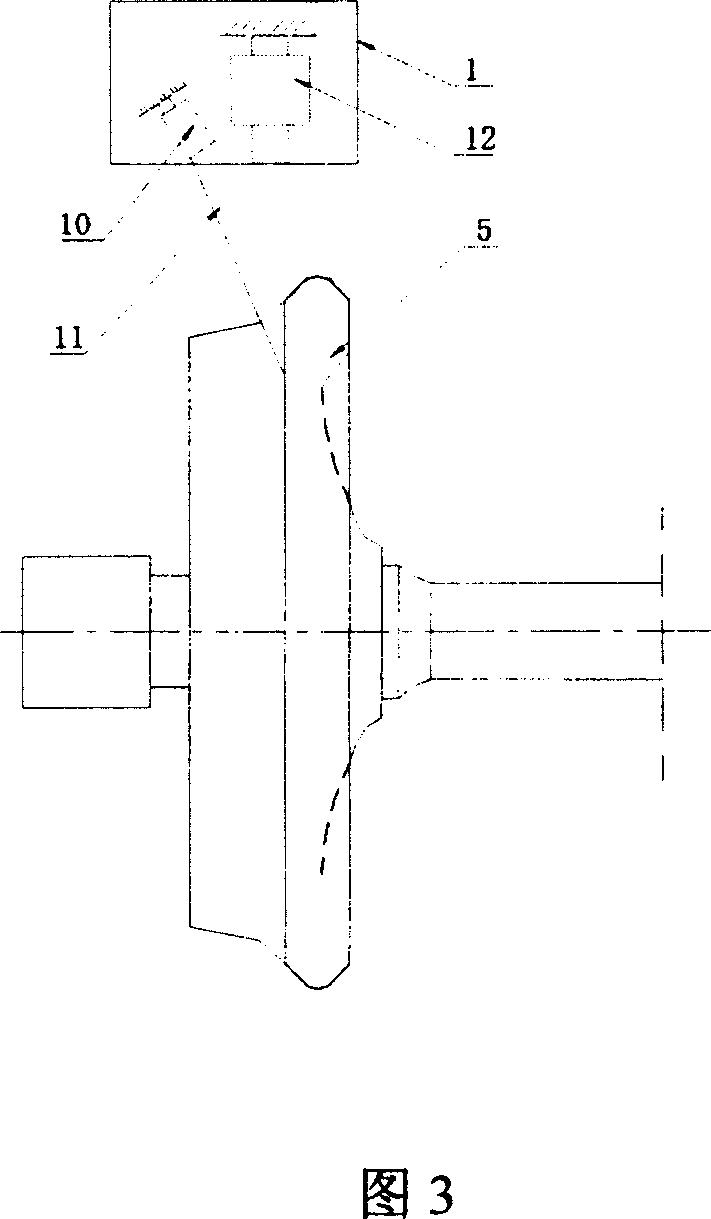

[0034] The present invention will be further specifically described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

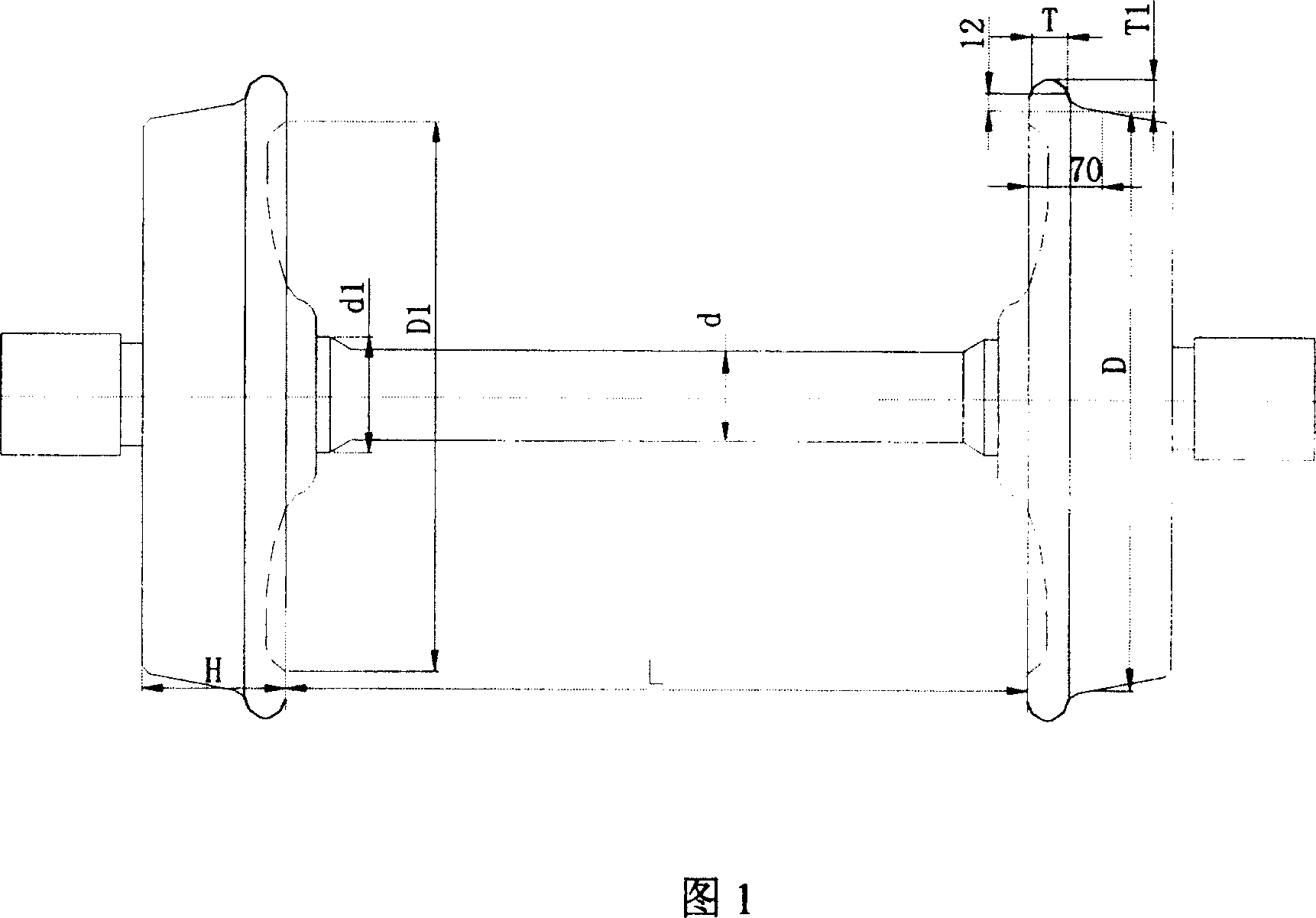

[0035] Fig. 1 is a schematic diagram of the profile of the wheel set and the parameters to be measured. The geometric parameters of the wheel set that can be measured by the present invention include: wheel set tread wear (T1-27), axle central diameter d, wheel seat diameter d1, wheel rim thickness T, Wheel diameter D, wheel rim width H, rim inner diameter D1, maximum wheel diameter difference of the same wheel set, wheel set inner distance L, three largest differences of wheel set inner distances, wheel set tread scratches and peeling, wheel rim thickness (D- D1) / 2. Except for the parameters of axle central diameter d, the largest wheel diameter difference of the same wheel set, the inner distance L of the wheel set, and the three largest differences in the inner distance of the wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com