Liquid crystal distributor

A dispensing device and liquid crystal technology, applied in the direction of spraying device, spraying device, identification device, etc., can solve the problems of deterioration of liquid crystal material 14, increase of manufacturing cost, deterioration of liquid crystal material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below with reference to the drawings.

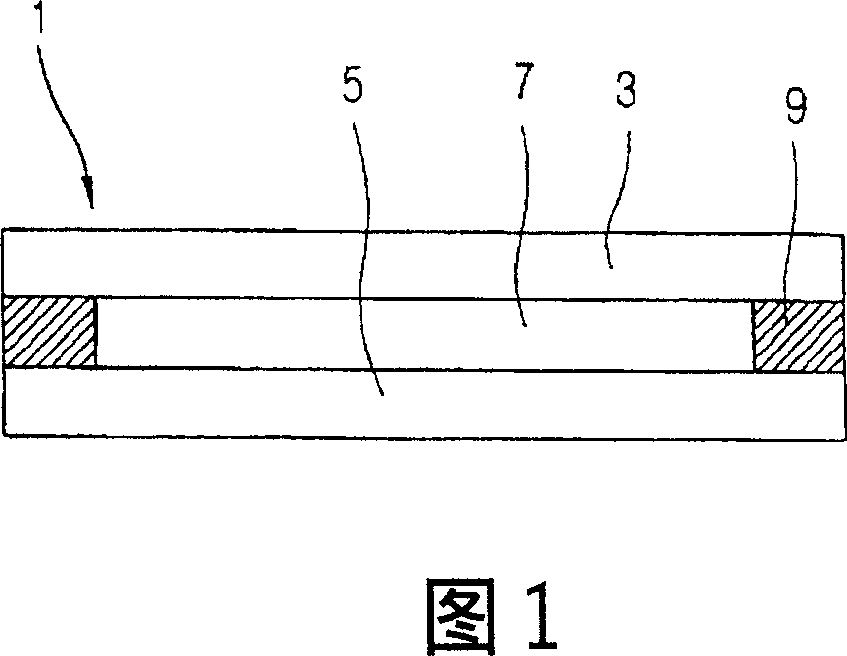

[0043] Fig. 4 is a cross-sectional view of a liquid crystal display device manufactured according to the liquid crystal dispensing method of the present invention. In Fig. 4, before the lower substrate 105 (i.e. TFT substrate) with many driving elements and the upper substrate 103 (i.e. CF substrate) with many color filters are bonded together, a series of droplets can be evenly spaced The liquid crystal material 107 is dispensed at intervals on the surface of the lower substrate 105 having the driving elements. Additionally, or alternatively, a liquid crystal material 107 may be dispensed on the upper substrate 103 with color filters. In addition, a sealing pattern may be formed along the periphery of the lower substrate. It is also possible to form the seal pattern 109 on both the upper and lower substrates 103 and 105 . The sealing pattern 109 may include a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com