Modular force-measuring cell for a weighing scale, and weighing scale

A force-measuring element and modular technology, applied in weighing, measuring devices, weighing equipment using elastically deformable parts, etc., can solve the problem of the thermal effect of the storage module on the force sensor, eliminate local temperature effects, save energy Cost, effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

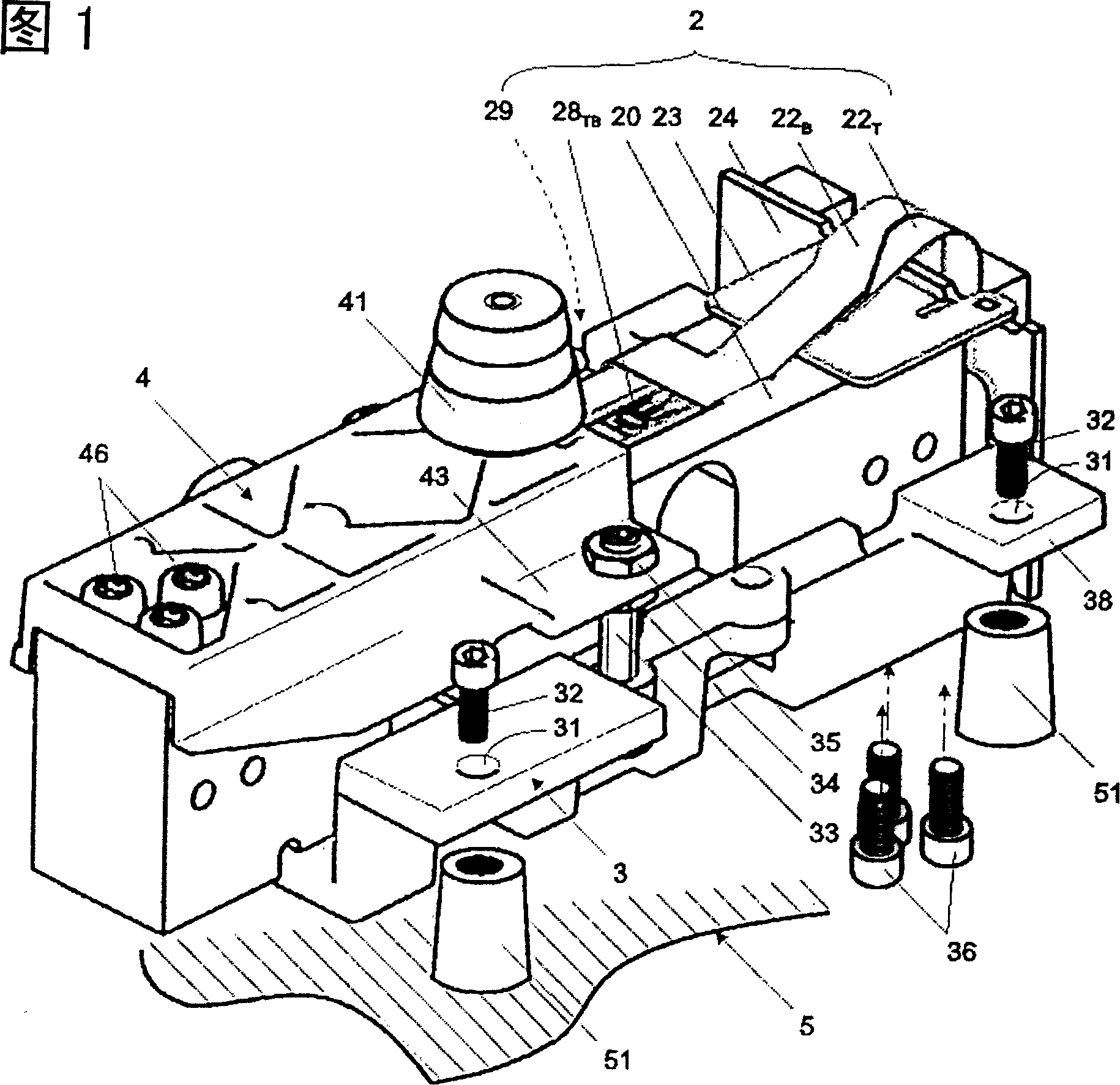

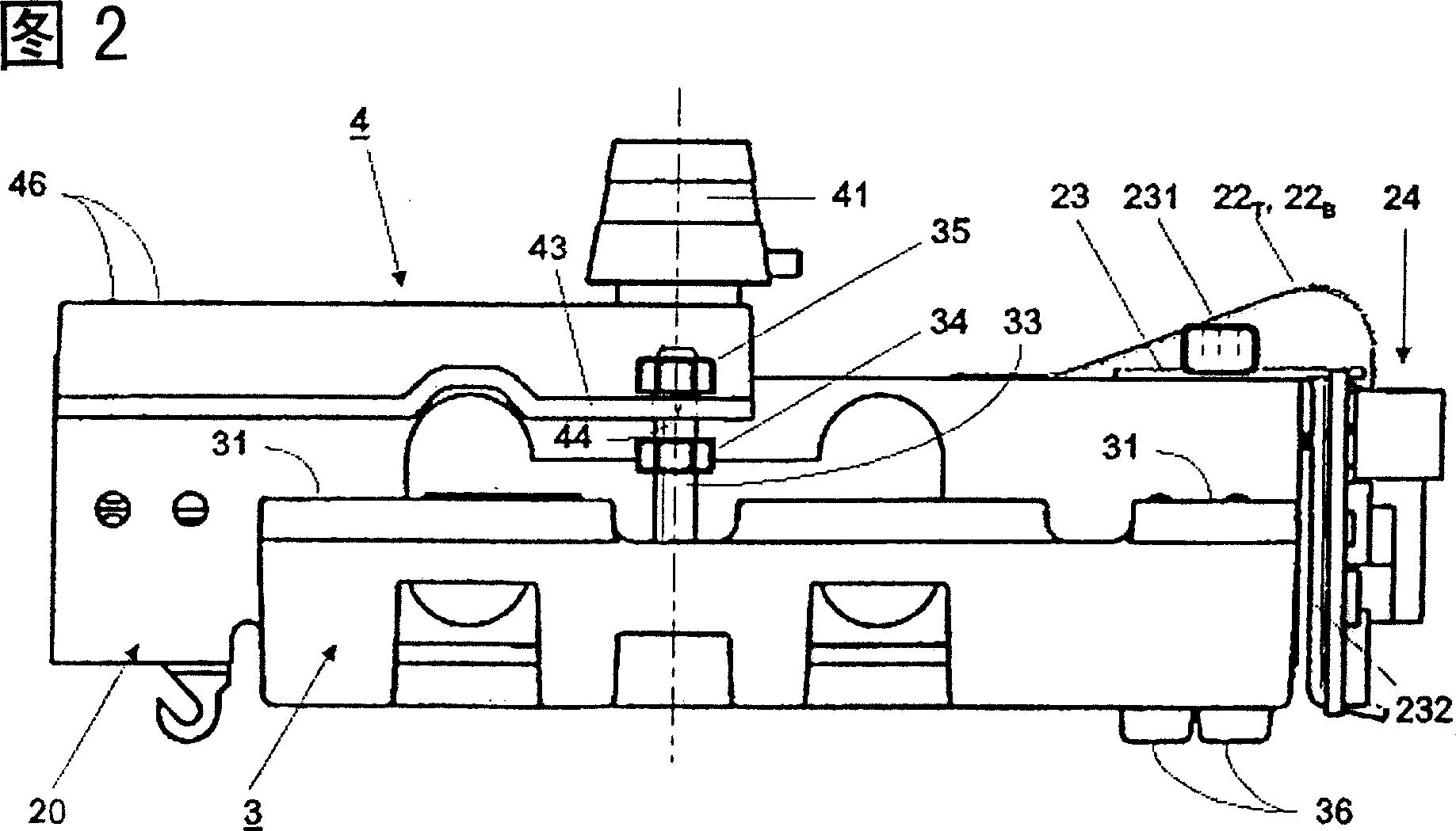

[0042] Figures 1 and 2 illustrate a modular load cell 2 according to the invention, which is connected to a weighing tray frame 4 and a fastener 3 by screws 36 and 46, respectively, and which consists of a load cell with a sensor 28, The force sensor 20 of 29 is composed of a circuit module 24 with a memory module 245 for storing compensation data and at least one circuit arrangement 243, 244 for converting an analog measurement signal (see also FIG. 5 ).

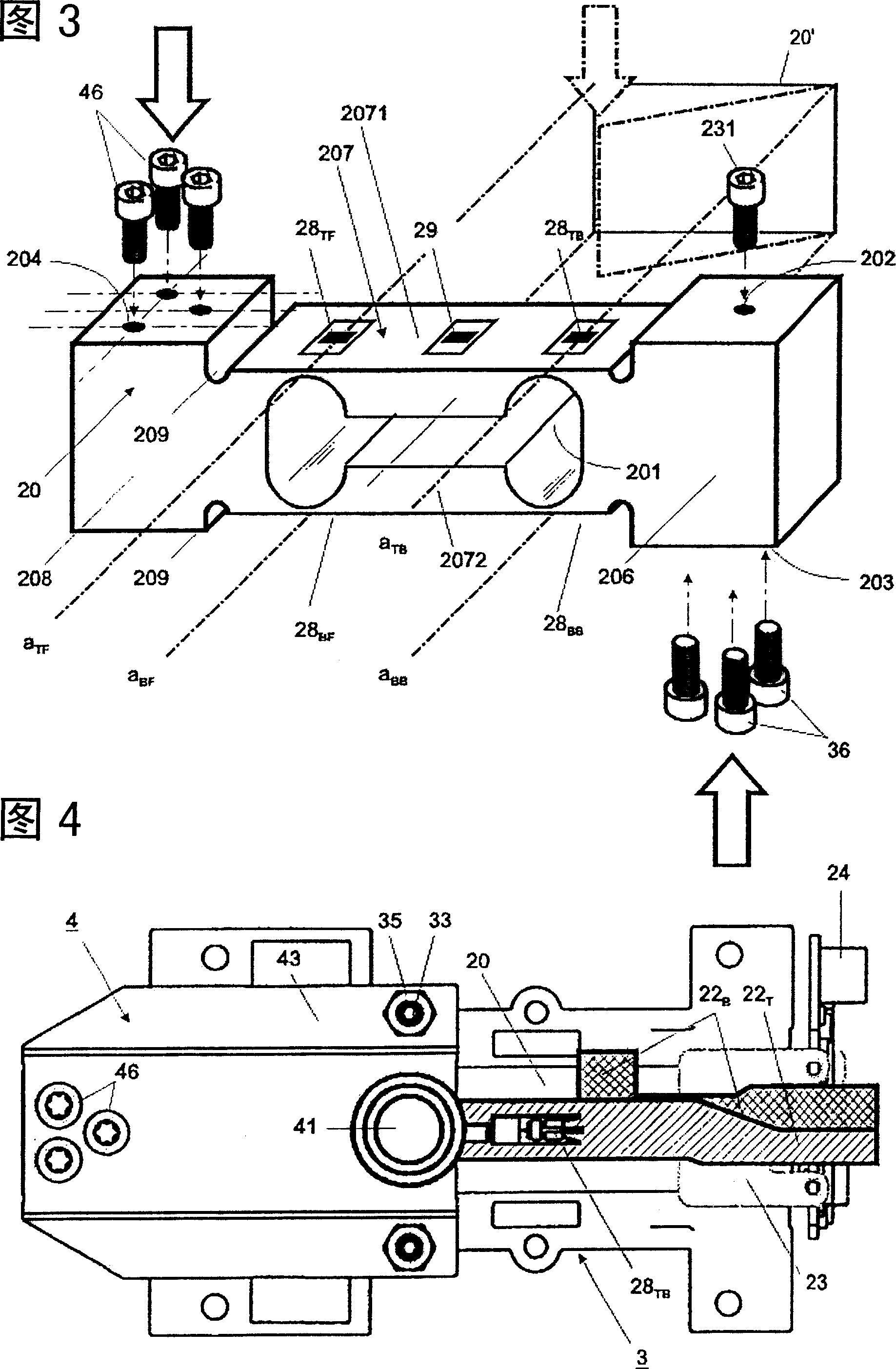

[0043] The force sensor 20 shown in a preferred embodiment of FIG. 3 has a deformation body 207 designed as a parallelogram measuring element with horizontal parts 2071, 2072 (see FIG. 3, element 20'), the two horizontal The parts are pivotally guided in the manner of a parallelogram linkage. The deformation body 207 connects the weighing frame-mounted fixing part 206 of the force sensor 20 to the force introducing part, in this case the load receiving part 208 . In order to decouple the stress field of the deformation bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com