Long roll gap roll sequeezer for fibre fabric dewatering

A technology of fiber fabrics and roller presses, which is applied in the direction of paper machines, press parts, textiles and papermaking, and can solve problems such as increased stress and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

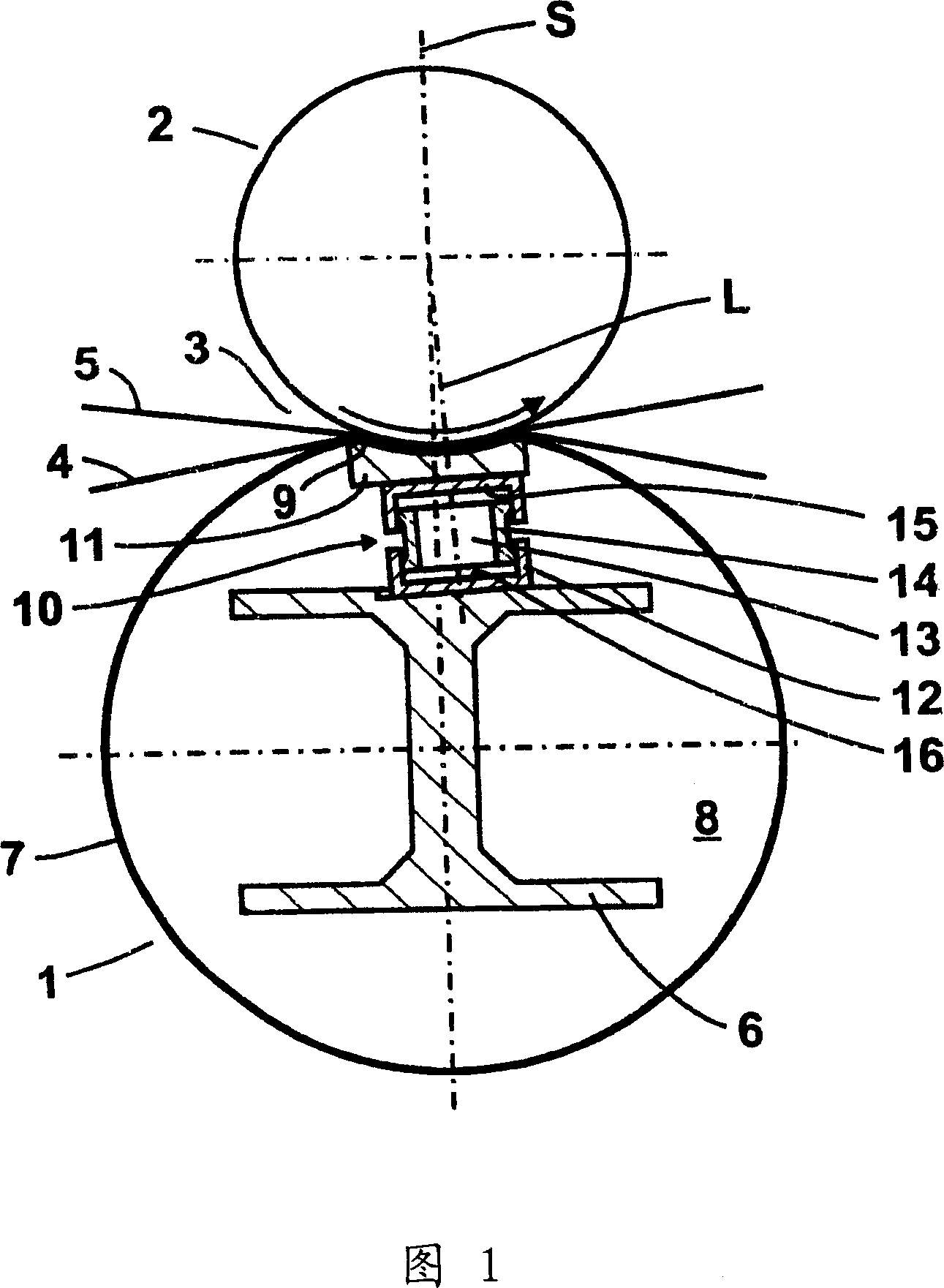

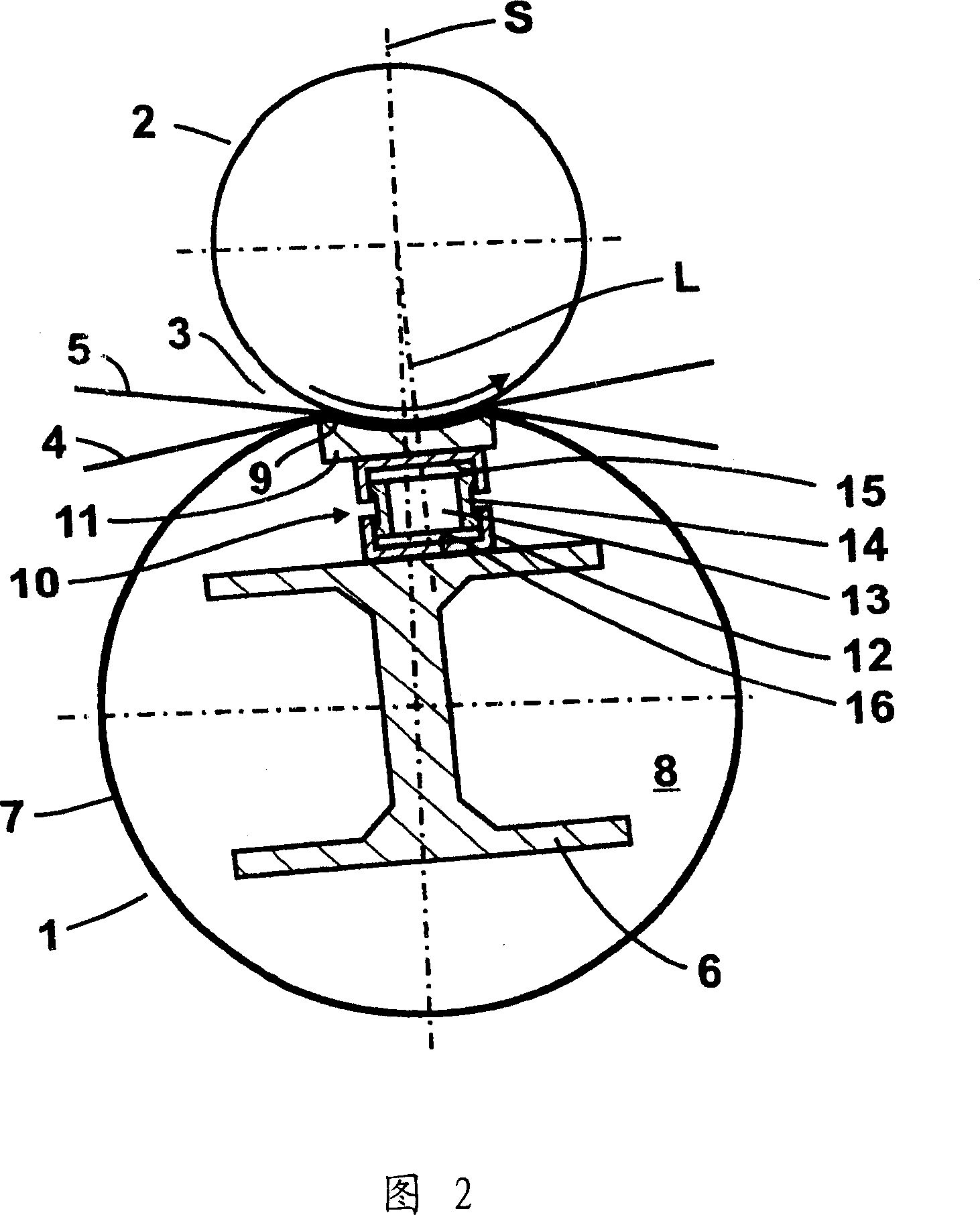

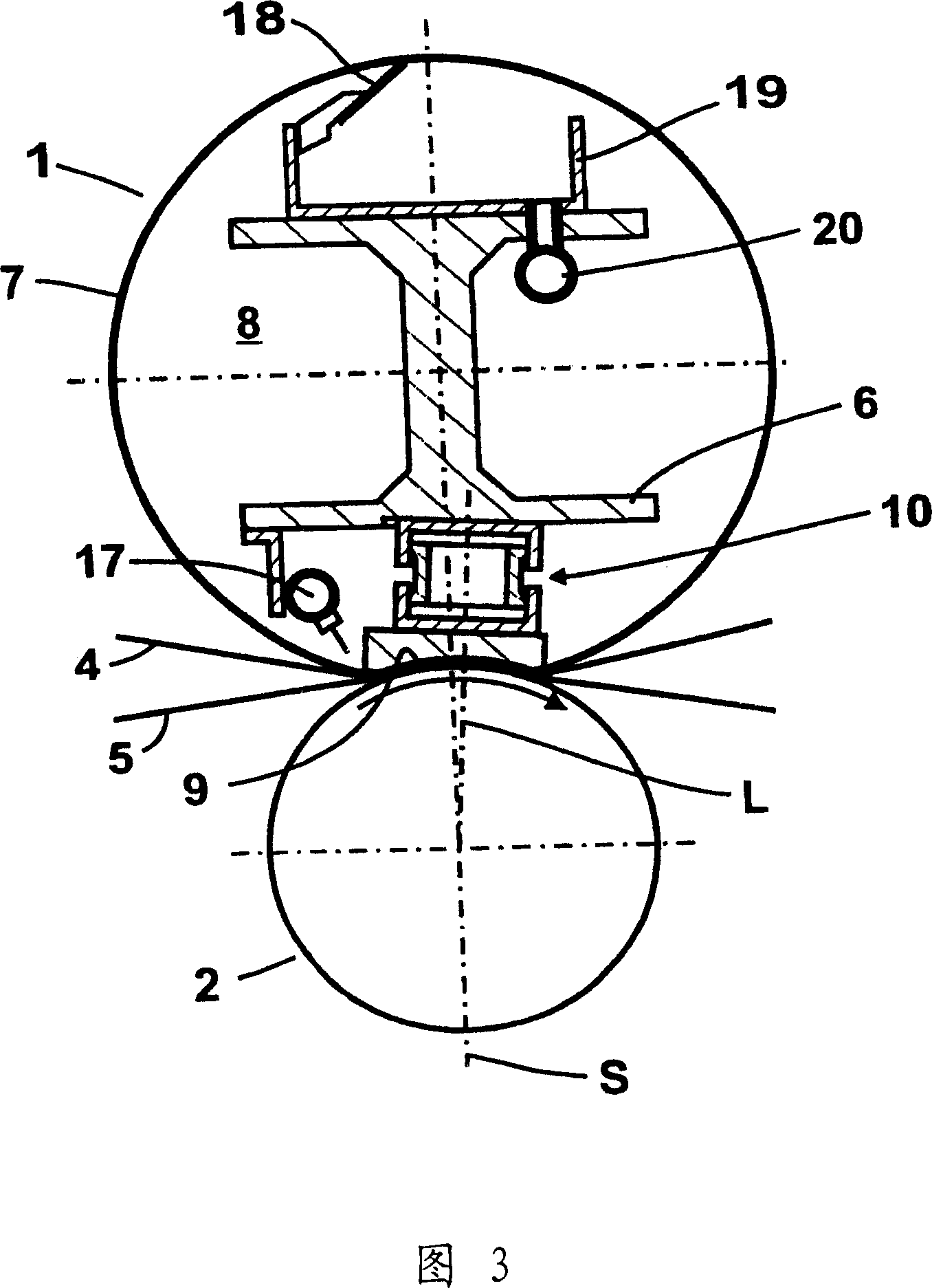

[0016] Figure 1 shows a long nip roller press for dewatering fiderous webs, especially paper webs, which may be part of a paper machine.

[0017] A long nip roller press consists of a long nip press roller 1 and a driven counter roller 2 which interact within a press nip 3 . The long-nip press roll 1 and counter roll 2 define with their roll centers a superposition plane S, where superposition plane S extends vertically. Optionally, the long nip press roll 1 and the counter roll 2 can also be arranged in such a way that the superposition plane S extends at an angle or horizontally. At least one felt fabric 4 and fiber fabric 5 to be pressed are guided through the press nip 3 .

[0018] The long nip press roll 1 comprises a stationary support 6 and a roll mantle 7 rotatable about the support 6 and made of a flexible material such as rubber or plastic. The roll mantle 7 is tubular and is fixed at its ends to a mantle (not shown) positioned so as to be rotatable on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com