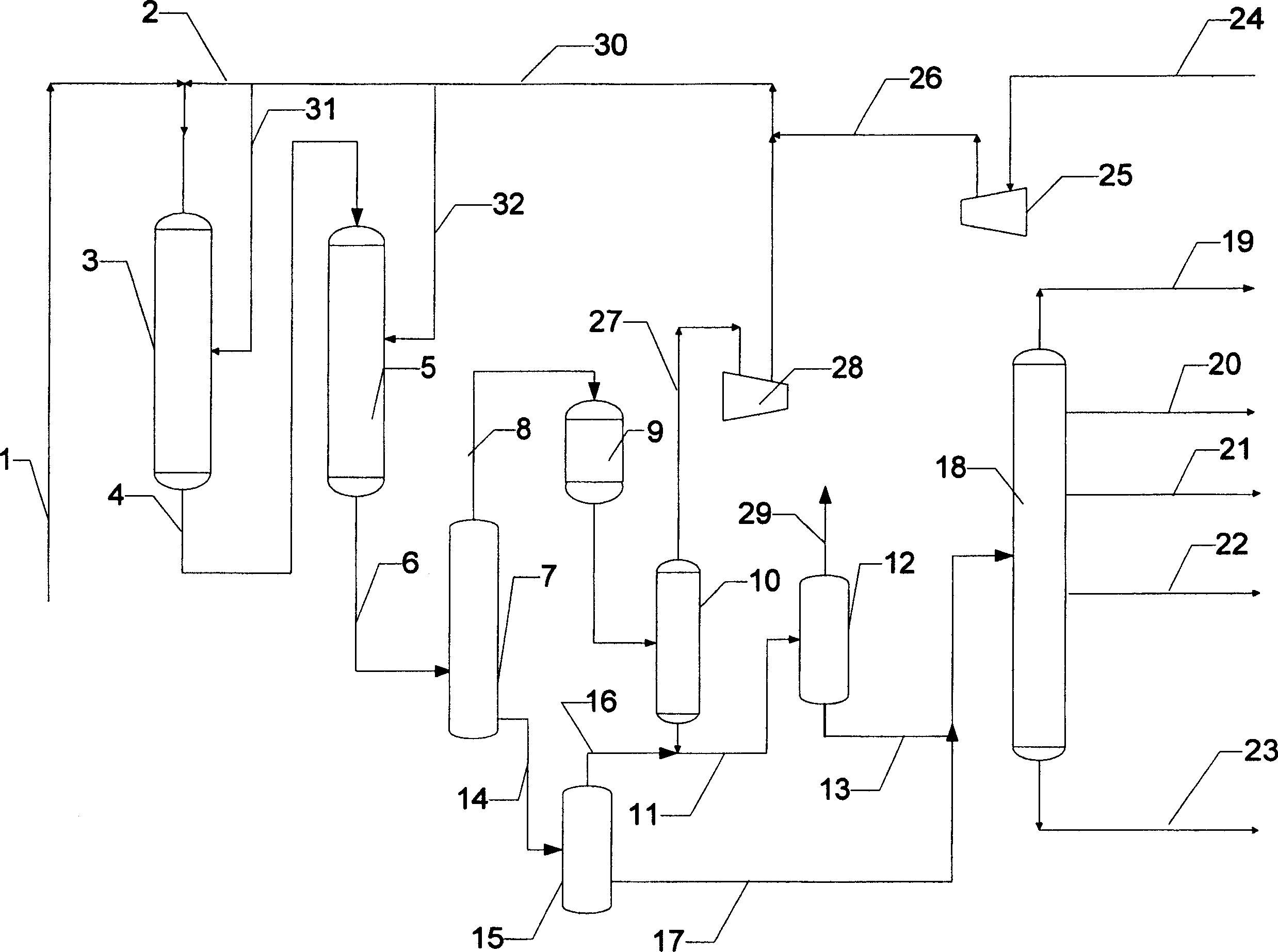

Medium pressure hydrocracking process for preparing jet fuel

A technology of hydrocracking and jet fuel, which is applied in the field of hydrocarbon oil cracking, and can solve problems such as multiple equipment, increased equipment investment, and large circulation of kerosene fractions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Compared with Comparative Example 1, the hydrocracking reaction effluent of this example is subjected to hydrotreating with the gas phase stream after high-pressure separation, and other conditions are the same. Tables 1 to 4 are the properties of raw oil, process operating conditions, product yield and main product properties.

[0034] Contrast result shows, the present invention has reached production qualification under the situation that catalyst volume increases very little # Jet fuel requirements, while product distribution and other product properties have changed little.

Embodiment 2

[0038] Compared with Comparative Example 2, the hydrocracking reaction effluent in this example is subjected to hydrotreating with the gas phase stream after high-pressure separation, and other conditions are the same. Tables 5 to 8 are the properties of raw oil, process operating conditions, product yield and main product properties.

[0039] Contrast result shows, the present invention has reached production qualification under the situation that catalyst volume increases very little # Jet fuel requirements, while product distribution and other product properties have changed little.

[0040] Raw oil properties

[0041] Comparative example 1

[0042] * Based on fresh ingredients

[0043] Product Distribution (Based on Fresh Raw Materials)

[0044] Comparative example 1

[0045] Raw oil properties

[0046] Comparative example 2

[0047] * Based on fresh ingredients

[0048] Product yield (based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com