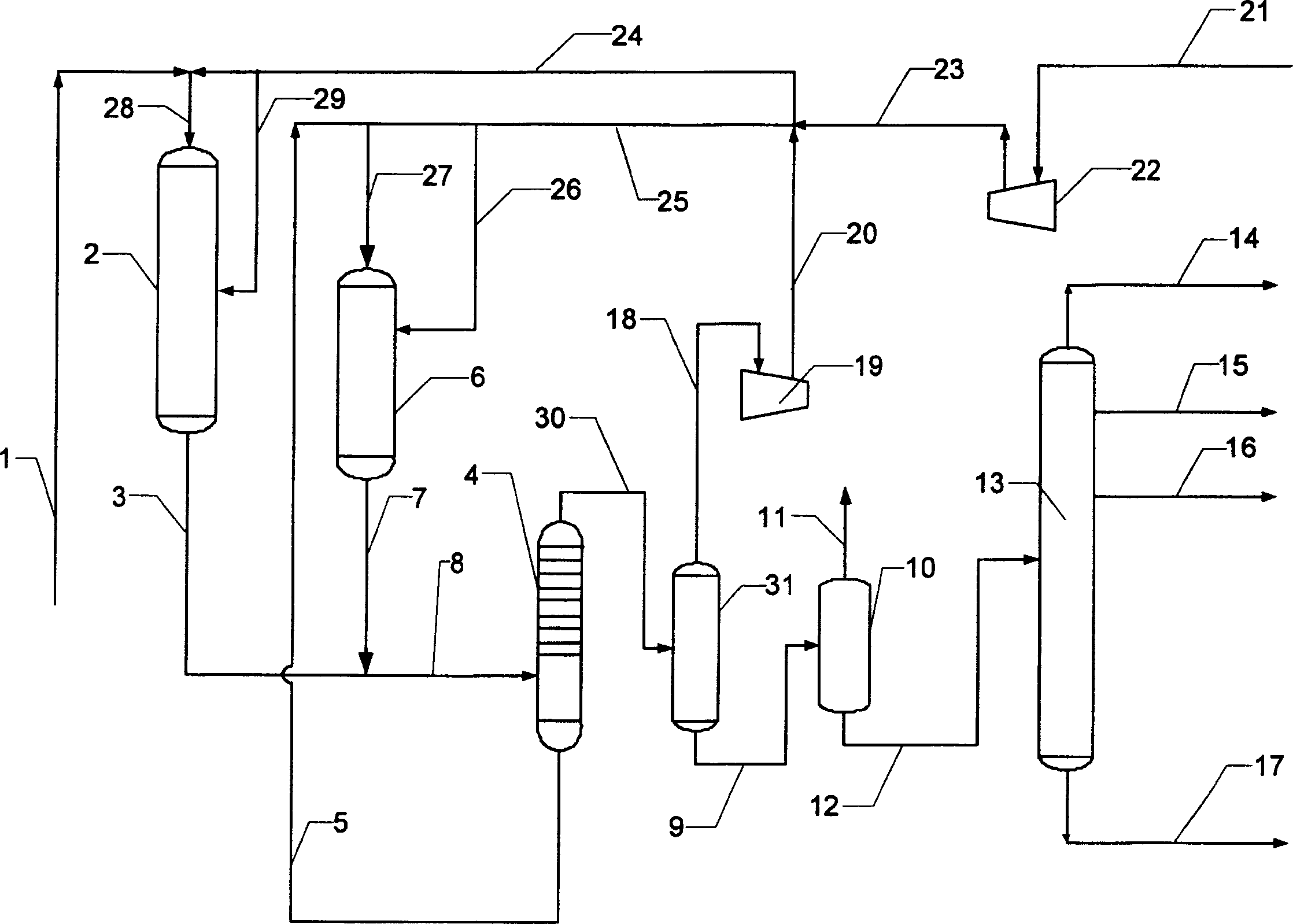

Medium pressure hydrogenation method for maximumly producing high quality diesel fuel

A diesel and medium-pressure technology, which is applied in hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of increased system pressure drop, increased hydrotreating reactors and catalysts, and increased circulating hydrogen flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The test raw material is a mixture of 46 wt% catalytic cracking diesel oil, 54 wt% atmospheric third-line distillate oil, and vacuum first-line distillate oil. According to the product plan of producing high-quality diesel fractions, the fractions above 370°C are recycled through the hot high-pressure separator. Hydrocracking reactor 6. The properties of raw oil, process conditions and product distribution are listed in Table 1, Table 2 and Table 3 respectively, and the yield of diesel fraction (150~370° C.) in Table 3 is 92.0% by weight. Table 4 lists the properties of naphtha fractions (65-150°C) and diesel fractions (150-370°C). It can be seen that naphtha has high aromatic potential, while diesel fractions meet the requirements of the World Fuel Oil Standard II, low sulfur and low Aromatic diesel requirements.

[0038] Raw oil properties

[0039] Hydrocracking operating conditions

[0040] * The amount of raw oil processed by the hydrocracking ...

Embodiment 2

[0044] The raw material for the test is a mixture of 20 wt% catalytic diesel and 80 wt% vacuum gas oil. According to the product plan of producing more high-quality diesel fractions, the fractions above 370°C are recycled back to the hydrocracking reactor 6 through thermal high fractionation. The properties of raw oil, process conditions and product distribution are listed in Table 5, Table 6 and Table 7 respectively, and the yield of diesel fraction (150~370° C.) in Table 7 is 82.0% by weight. Table 8 lists the properties of naphtha fractions (65-150°C) and diesel fractions (150-370°C). It can be seen that naphtha has high aromatic potential, while diesel fractions meet the requirements of the World Fuel Oil Standard II, low sulfur and low Aromatic diesel requirements.

[0045] Raw oil properties

[0046] Hydrocracking operating conditions

[0047] * The amount of raw oil processed by the hydrocracking reactor includes the unconverted oil of the hydrocrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com